Wrapping machine how "universal"?

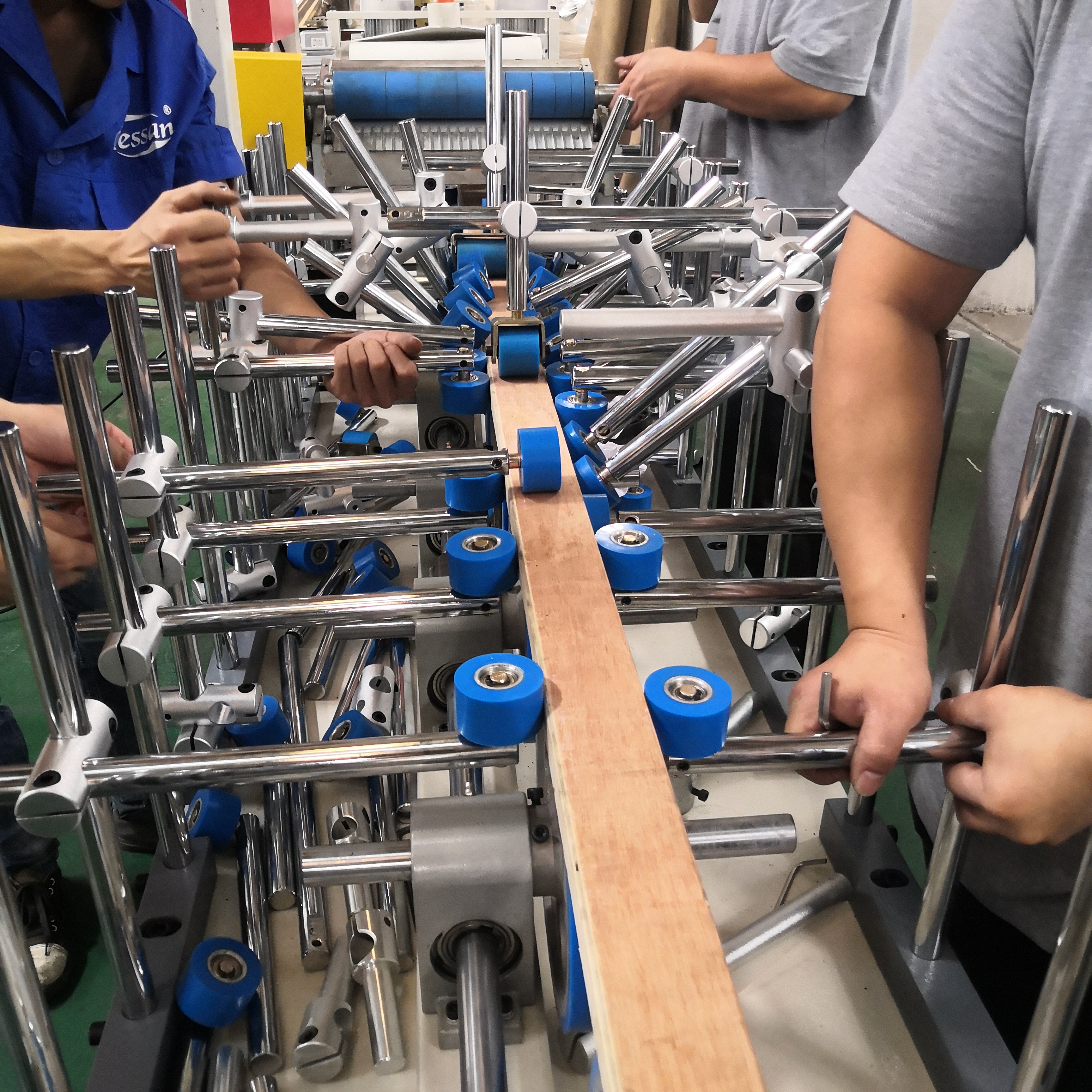

Universal wrapping machine is suitable for the production of PVC, decorative paint paper

and solid wood veneer laminated on the surface of various lines such as wood, aluminium-plastic

profiles, foam materials and so on. Instead of the traditional painting process, it is used for the

production of surface laminating of door set line, skirting line, button plate, curtain rod, window sill,

aluminium alloy doors and windows, photo frame, etc.

1、Substrate material: wood lines, MDF, wood-plastic, plastic, PVC, aluminium profiles and other lines.

Substrate requirements: for the rule line profiles, can have grooves, curved surfaces, but each point

longitudinally must be a straight line, have a certain degree of pressure resistance, the length of the

general length of more than 40 cm to unlimited length.

2, veneer materials: PVC decorative film, decorative paper, solid wood veneer, Boeing board, composite

aluminium film. The width is determined according to the needs of the substrate and the selected model,

generally less than 50 cm. For example, the widest laminating width of 300 universal wrapping machine is

30cm. Generally used in rolls. There are also extra wide profiles of about 100cm on the market. Solid wood

veneer can be rolled or single, solid wood veneer is generally the bottom with a non-woven fabric, without

non-woven surface material shall not be permeable to glue, in the corner and easy to break.

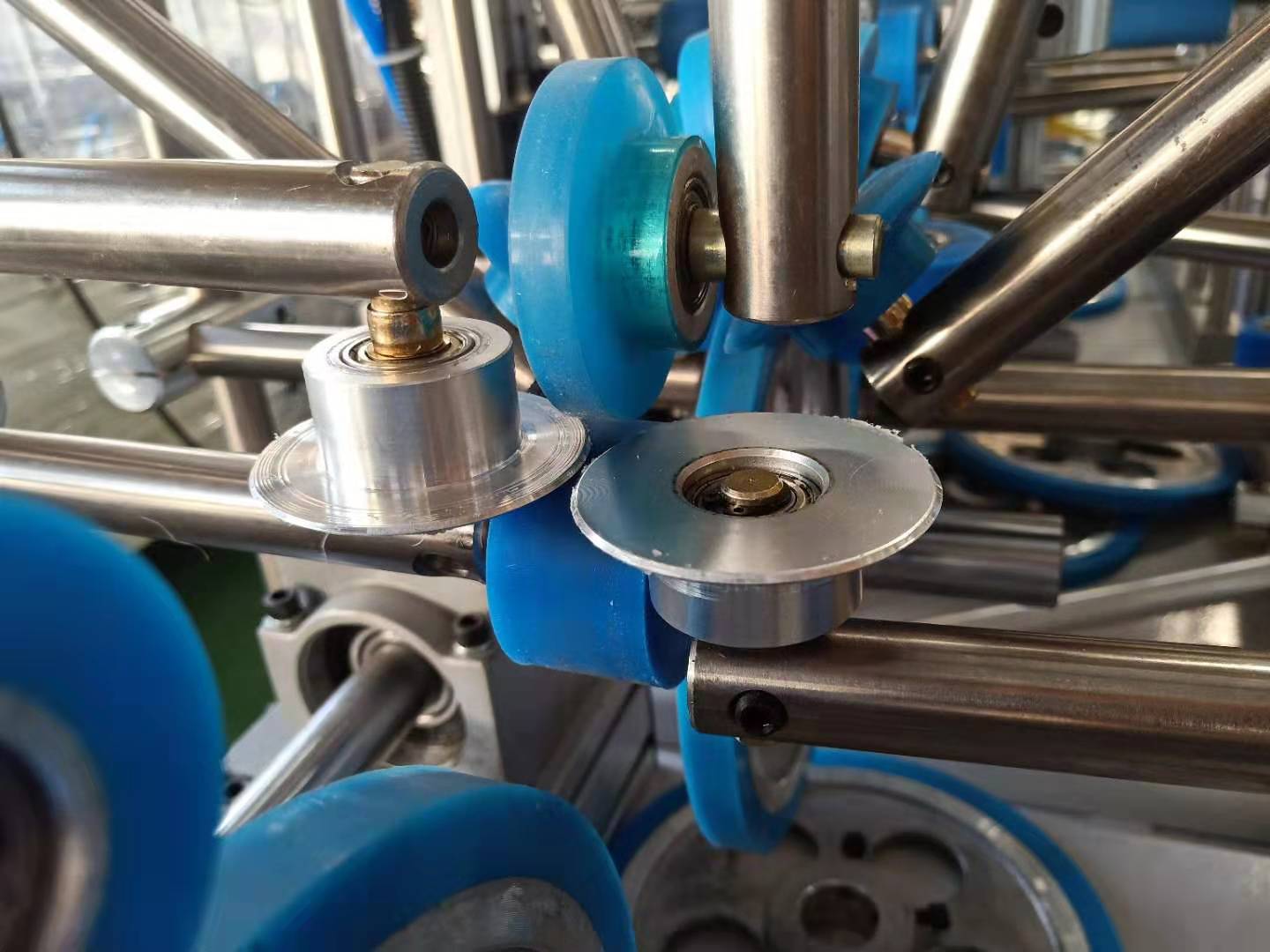

Using a variety of moulding pressure wheel, simulating manual veneer action, the surface decorative materials

attached to the surface of the substrate, generally choose the centre line of the profile or the highest point or

the lowest point as the starting point, will be the pressure wheel along the profile surface contour, point by point,

in turn, the fixed position, the formation of the profile contour of the envelope.

Daily maintenance:

1, the working environment should be kept clean to prevent dust from falling into the gluing system and affecting

the quality of gluing.

2、 The lubricating oil in the gearbox should be replaced with new lubricating oil after 1 month of initial use, and

then it should be replaced every half a year, and it should be replaced once every 3 months when the workload is heavy.

In the summer when the temperature is high, the viscosity of the reducer lubricant should be replaced. When the temperature

is low in winter, the reducer lubricant with small viscosity should be replaced. Transmission system: sprocket drive, chain part of

the monthly grease 1 time. If it is gear transmission system, the turbine seat should be greased once every fortnight, and the turbine

seat without oil seal should be added with grease twice a week.

3、 When the work is finished, the main power must be switched off.

4、 When repairing or adjusting the parts, it should be handled by relevant professionals.