What is the method used by the laminator to remove the dust from the boards?

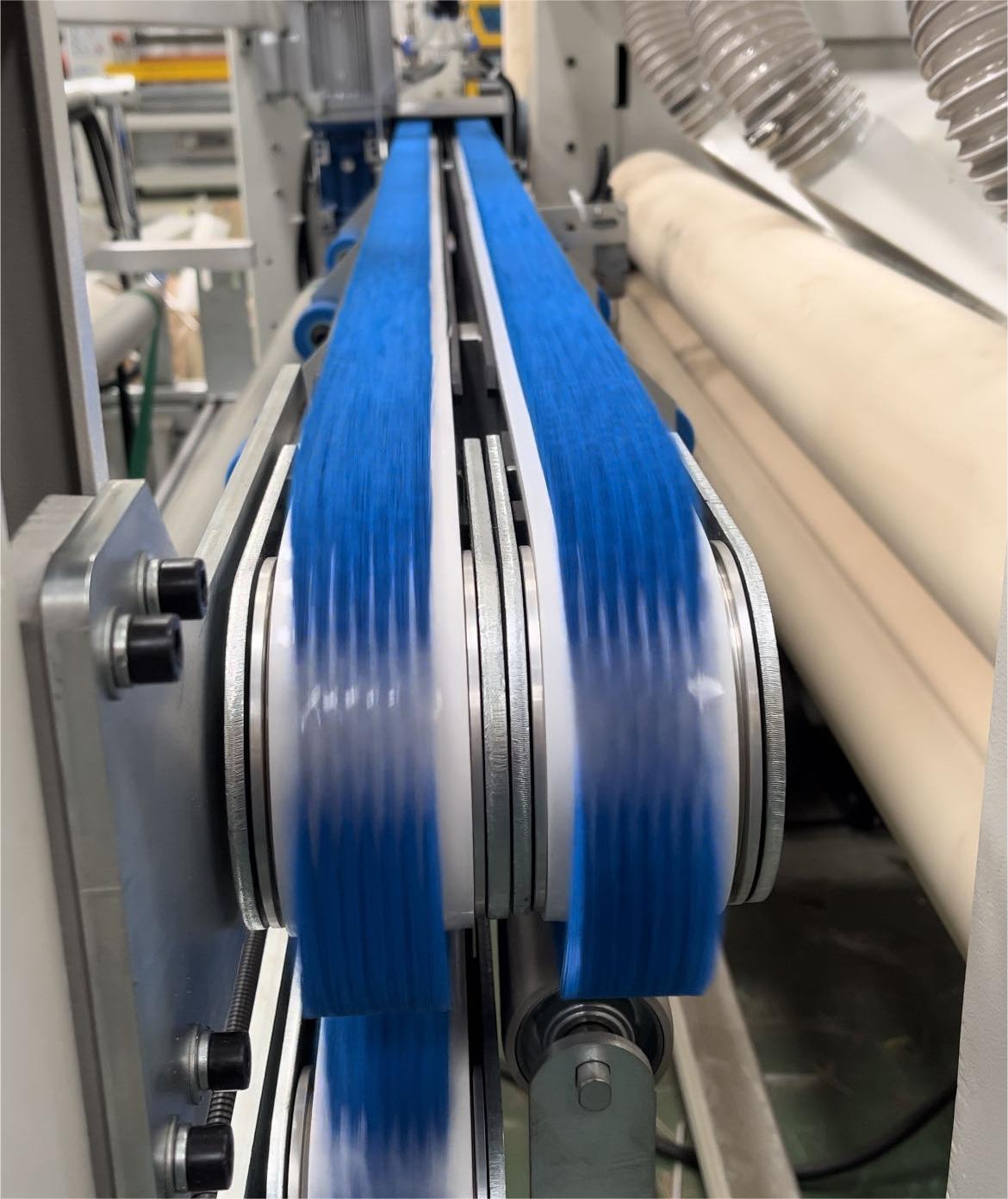

1. Static water plus brush duster: Static electricity attracts dust and particles to attach to the surface of the sheet.

The use of anti-static water reduces the generation and build-up of static electricity, thus reducing the likelihood

of the sheet attracting dust. Use a belt brush to dust the sheet.

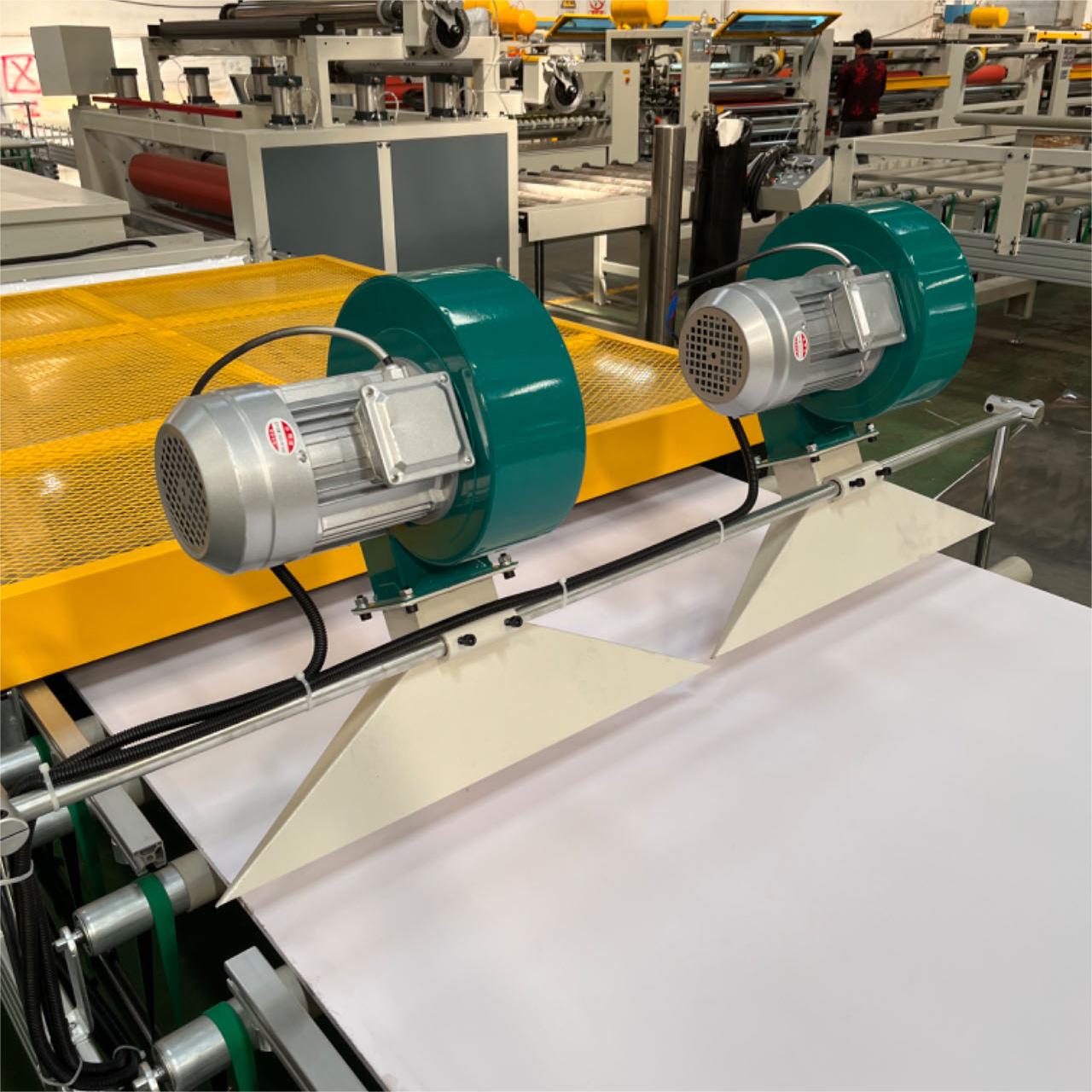

2. sisal double-sided brush: use the sisal material brush to wipe the surface of the plate to remove

the large dust and large particles attached to it.

3. High compressed air blowing: Use compressed air blowing gun or nozzle to send air into the working area

of the flat laminating machine to remove dust and impurities on the surface of the sheet. Aim the nozzle

at the surface of the sheet and use the airflow to blow the dust away. This method can quickly and effectively

remove light dust from the surface.

4. Sticky dusting paper: Use sticky dusting paper or sticky dust roller to adhere and remove dust and particles

from the surface of the sheet. Press the sticky paper gently onto the surface of the sheet and then tear it off

quickly to adhere the dust to the paper.

REGULAR MAINTENANCE:

It is important to regularly maintain and clean the sheet dusting equipment. Follow

HESSAN's recommendations for proper maintenance procedures. This includes cleaning filters, replacing worn

parts, lubricating mechanical parts, etc. Regular maintenance ensures proper operation of the equipment and

keeps dust removal consistent and efficient.