What is technology veneer?

01 What is technology veneer?

Technology veneer is the use of the principle of bionics, fast-growing wood processing, through the restructuring of landscaping, made of wood finish materials with better performance.

Material characteristics

Compared with natural wood veneer, technology wood veneer texture, color is more rich and diverse, not only eliminated the natural wood veneer of dead knots, insect holes, white edges and other defects, the surface is smoother, more consistent color, and high wood utilization, easy to process, replicable, and popular price.

① corrected the natural defects of the veneer: virgin wood in the natural growth process, due to climate, geography, tree species and other reasons, the existence of defects and performance defects can not be avoided, the texture structure and color is not entirely in line with the needs of the product, science and technology veneer corrected the natural imperfections of the virgin wood to make up for the performance defects of the virgin wood veneer.

② rich texture and color: technology veneer using computer design, can be designed into a variety of textures and colors to meet the individual needs of consumers.

③ Wide range of raw materials: technology veneer raw materials from a wide range of sources, lighter color, easy to process wood can be used to protect forest resources.

④ Decorative width and size: technology veneer overcomes the limitations of natural veneer diameter level, according to different needs can be processed into different width sizes.

However, the production process of technological veneer is more complex, and the production process requires strict quality control in order to achieve satisfactory results.

Material Classification

. According to the texture, there are straight grain, mountain grain, durum grain, wave grain, point grain.

2. According to the species, there are teak, red oak, white oak, sour branch, ebony, iron knife, Sabbia, zebra, black walnut, cherry, chicken wing and so on.

Material production process

The production process of technological wood veneer includes chipping, staining, combining, gluing, pressing, edging, cutting and testing. The wood is processed and reintegrated to give it infinite variations.

02 Difference between natural wood veneer and technological wood veneer

1. Wood veneer types

"Natural veneer": natural wood is directly planed and cut into micro-thin veneer with a thickness of 0.2-0.5mm or so, which is widely used in the fields of furniture, luxury cars, airplanes, yachts' interiors, flooring, musical instruments and so on.

"Technology veneer": wood veneer industry "cloning technology", can imitate a variety of natural wood veneer texture, color and so on. Apply to furniture, doors and windows, decoration, flooring, wood crafts and so on.

2.Craft PK

Natural wood veneer: is completely with the original wood planing and become, without any artificial modification, retaining the natural texture and texture.

Technology veneer: it needs to go through a series of bleaching, coloring, restructuring texture and other processes.

Technology veneer can fill the wood defects: natural wood veneer more or less defective, color texture natural, it is difficult to coordinate. But technology veneer surface smooth, what effect to have what effect.

03 technology wood veneer fire problems

When it comes to wood products, we will certainly consider how its fire performance? This is related to the substrate and composite treatment process, different manufacturers and different brands have different treatment processes. Below, we will look at it together~

Substrate

We usually use most of the substrate is multi-layer board (including multi-layer flame retardant board), woodworking board, integrated board, osone board, paint-free board, particle board, oriented strand board, WoXiangBan, gypsum board, cement board, calcium silicate board, acrylic board, plastic wood board, rock board, artificial board, fire prevention board ......

Class A Fireproof

Wood veneer and aluminum foil are laminated together after a special composite process, as a kind of veneer material, overlaying on the surface of building boards, it is a kind of green and environmental protection material integrating flame retardant and easy to construct, and it can reach the fire protection requirement of A-class fire prevention.

Super ductility

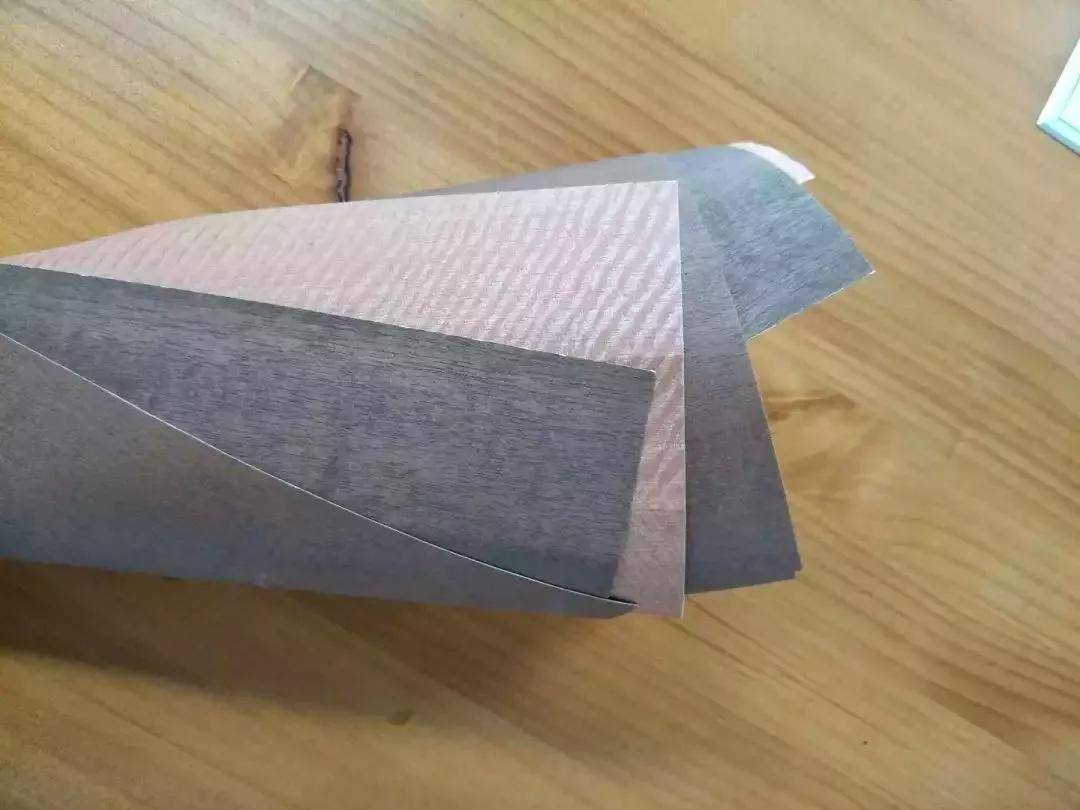

As we all know, wood veneer, as a natural material, is very brittle and prone to cracks and even breakage after bending. But after the aluminum foil laminated veneer, the ductility is greatly enhanced, can be bent and folded, suitable for curved molding wall, and even right-angle bending.