what is PUR ?

In the custom furniture industry, you may often hear PUR honeycomb flat laminating line, PUR flat laminating line and other synonyms, so what is PUR in the end? Today I will give you a simple "chemistry class" to understand PUR. PUR is actually an abbreviation for PolyUrethane Reactive. To really understand the PUR glue, you can be familiar with and understand a chemical formula: 1 mol of water molecules and 2 mol of isocyanate reaction. As you can see from the chemical equation above, PUR glue is glued and cured by the reaction of the isocyanate (NCO) in its molecule with water in the air, which produces polyurea and carbon dioxide gas. Generally, before curing, PUR adhesive is a "prepolymer containing isocyanate" (i.e., small molecules with relatively small molecular weight). When heated, these small molecule pre-polymers begin to melt, thus transforming the adhesive from a solid to a liquid, making it easier to apply and glue. After sizing, these small molecules of prepolymer began to react with water molecules in the air, part of the prepolymer containing 3 or more isocyanate, is a PUR glue can crosslinking curing of important components, while water molecules play the role of crosslinking agent.

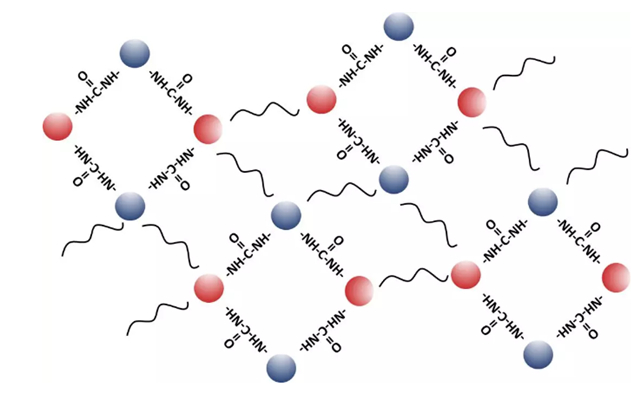

From the above reaction mechanism can also be seen, PUR glue and common EVA glue in the use of the principle of the difference between the EVA glue in the heating and melting did not occur "chemical reaction", just through the conversion between solid and liquid, to achieve the coating and bonding, the essence of its "physical changes The nature of the "physical change". PUR glue and water molecules in the air has a "chemical reaction", generated a new substance, the formation of a three-dimensional crosslinked network. This is also the EVA glue can be repeatedly heated and cooled to use, and PUR glue can only be used once, once the curing occurs to clean up very difficult reasons. Therefore, in the use of PUR glue in the process, the need for daily production after the completion of the equipment in the glue roll for a thorough clean-up, once forgotten or clean-up is not complete, the glue will be cured difficult to clean, affecting product quality.

First, the application of PUR glue As PUR glue is very easy to react with the water in the air, the way it is coated and stored with EVA glue is different, the shelf life is relatively short (unpacked up to about a year).EVA glue can be exposed to the air, and do not need to use a special melting machine, and PUR glue needs a special melting machine for melting. This special structure of the melting machine can maximise the PUR glue in the uncoated before and air isolation, while in the heating only from the heating plate nearest to the glue, to prevent unused PUR glue in the constant heating and cooling in the aging failure.

Second, the common PUR melting glue machine PUR easy to react with water characteristics, resulting in its construction window period can not be too long. After applying the glue, if it is exposed to air for too long, the PUR glue will lose its viscosity, resulting in bonding failure. For example, in the production process of flat stickers, after the plate is glued, it should be pressed immediately to ensure that the glue is active. (Information about PUR flat paste can be clicked: a flat paste production line capacity is how big?) At the same time, the reaction between PUR glue and water and need a certain time and temperature to achieve a complete reaction. Therefore, the general use of PUR adhesive bonding products, need a certain period of recuperation and recuperation temperature (with the PUR adhesive formula, generally 24 ~ 48 hours), especially in the winter low temperature, should pay extra attention to the recuperation time and temperature control, in order to avoid the occurrence of the phenomenon of the product deglossing.

Third, the performance of PUR glue laminated products EVA glue "reversibility" decided by its closed products in the high temperature and high humidity resistance is slightly less than the performance of the PUR glue is just the opposite. Because water molecules are involved in the curing reaction of PUR, PUR adhesives are better than EVA adhesives in terms of resistance to moisture and humidity. At the same time, from a molecular point of view, after curing the PUR glue has formed a three-dimensional crosslinked network, and will not be the same as EVA glue, will be softened by high heat will lead to deglossing, and therefore in the heat-resistant is also superior to EVA glue flat laminatedproducts.

Fourth, the conclusion of the custom furniture industry, the current PUR glue is mainly used in decorative panels of flat paste, as well as acrylic, PET, PVC and other surface materials,laminating or wrappingproduction. In the application of flat paste, PUR glue paste quality and product performance is better than EVA glue, but the equipment investment is relatively high, the glue cost is relatively large and more complex operation and use, is between the laser edge sealing and EVA glue between an investment choice. In the application of flat paste, PUR glue and most of the board bonding good, easy to roll coating, continuous production characteristics, so that it is in the production of decorative panels to obtain more and more applications.