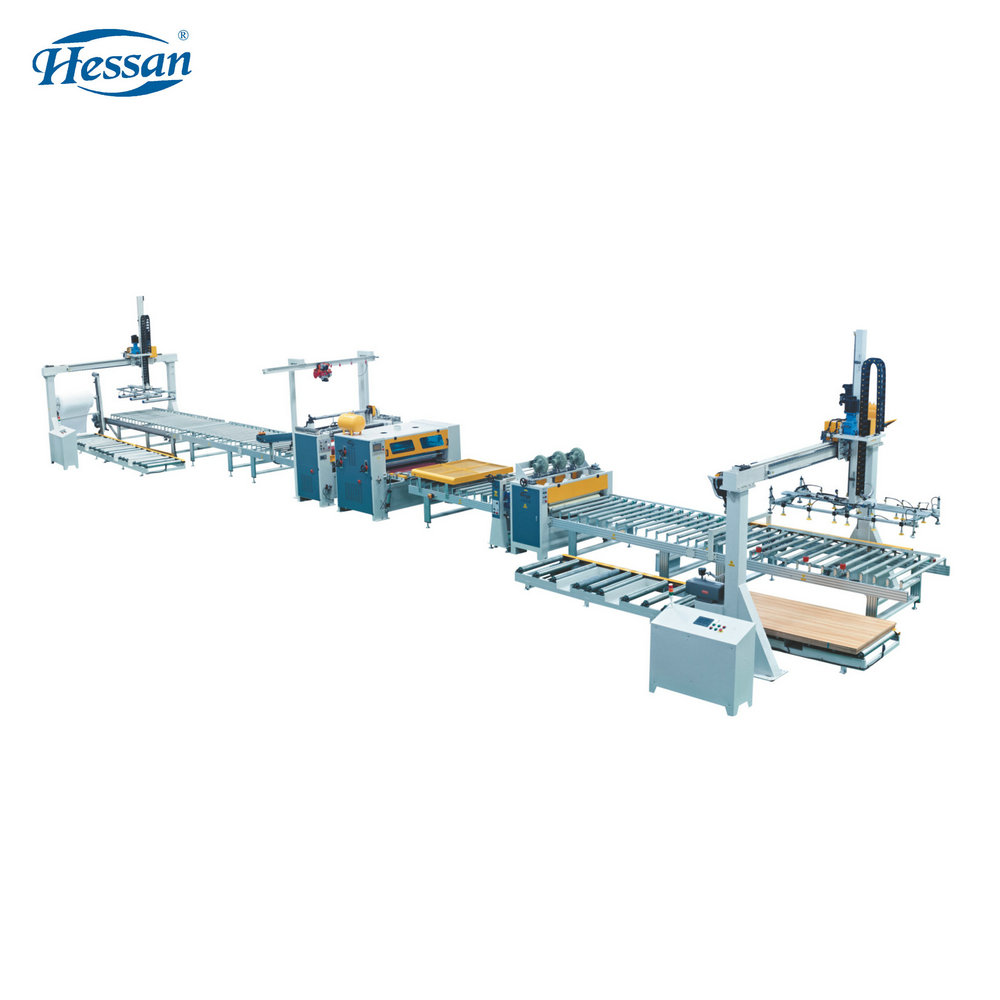

PUR hot melt adhesive flat laminating production line Details

PUR Flat Laminating Production Line is suitable for laminating surface materials of different materials on the surface of different plates. Its hot roller coated reactive hot melt adhesive (PUR) on the surface of the plate, the surface material and the substrate aligned with the overlay, to achieve the adhesive effect. Its glue has adhesion, cold resistance, high temperature resistance, waterproof, and other characteristics. The production line of the numerical control function, fully automatic line two people can operate the production, enterprises no longer have to worry about the lack of personnel, low efficiency, etc., is the ideal equipment for sheet laminating.

Scope of application; PUR glue is applicable to a wide range, such as a variety of panels on the lamination of aluminum foil, flooring composite, cabinet panels, honeycomb furniture (door), aluminum composite panels, fire prevention boards, melamine boards, etc., the

PUR sheet flat laminating machine is a sheet laminating equipment, although the structure of the flat laminating machine looks relatively simple, but its processing efficiency is still relatively fast, but also able to adapt to different sizes of panels, the following gives you the common failures of PUR wood panel laminating machine to cope with.

1, curling. If curling occurs during printing, it is recommended that you adjust the traction tension of the plastic film, you can also appropriately reduce the temperature of the hot roller of the press rollers, but also to control the temperature of the production process.

2, bubbles. PUR wood laminating machine production bubbles, you can clean the surface of the paper, but also color control of adhesives and thinning agent ratio problem, but also paper prints can be dried, adjust the humidity of the workshop.

3, wrinkles. PUR board laminating machine this phenomenon is more common, this phenomenon we should first adjust the guide roller conveyor belt, pay attention to the degree of neatness of the next paper, but also to adjust the pressure roller of the rubber roller and guide roller gap.

PUR board laminating machine operators should pay attention to:

(A) the machine manager in the view of the work handover book should pay attention to understand the work of the production of product quality conditions, equipment conditions, the handling of abnormal conditions and so on.

(B) before the production of the machine by the machine captain inventory of the machine personnel, and check whether the tools are complete, placed in the correct position, there is no debris on the machine. If the above situation occurs, then immediately organize and clean the end.

(C) Check the emergency switch and door safety device of PUR hot melt adhesive laminating machine. When found that the emergency switch and the insurance device failure, immediately stop the suspension of production, timely report to the supervisor and the Ministry of Equipment maintenance, and make a record.

(D) Fill in the material feedback sheet for the quality problems frequently occurring in the flat laminating process.

(E) for the shift has not been dealt with the abnormal situation to fill in the work handover book, clear handover to the opposite shift.

(F) Check whether the labeling and quantity of semi-finished products in the process are accurate, whether there is any abnormality in the quality, and give timely feedback to the machine manager and supervisor if there is any problem.

( G) check whether the materials for the production plan of the flat laminator of the current shift are in place, such as not in place shall be responsible for following up in place.