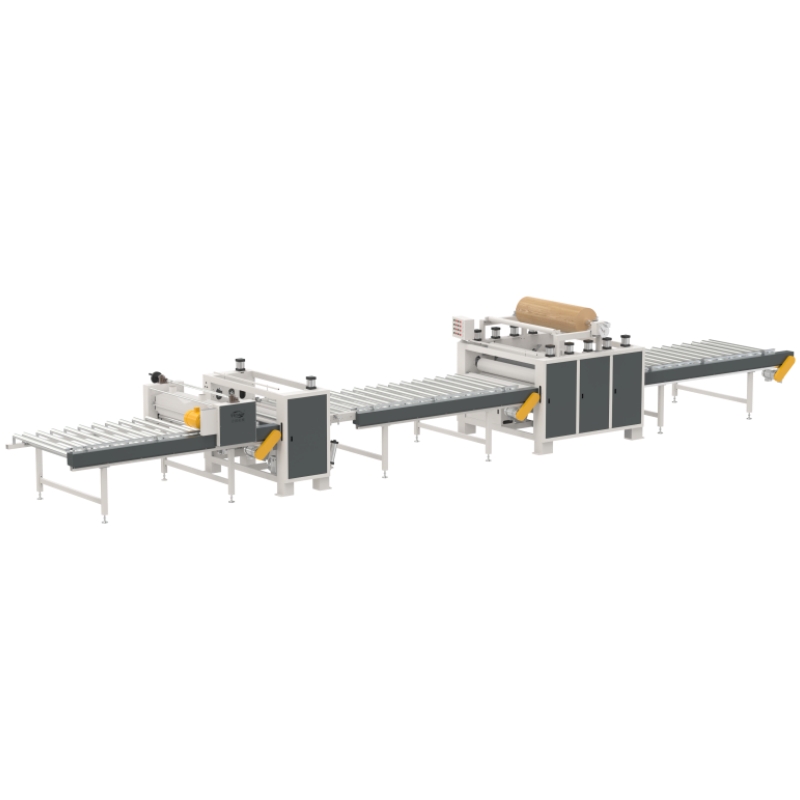

HY-PUR-1400D. Full automatic PUR HOT Melt glue laminating machine line. Hessan NEW HOT SALE full automatic PUR laminating machine. This machine is new designed in 2020, and hot sale in China. We have sold 50 more in China during Jan to April 2021. This machine can laminate Not only Transprent PET/PVC, HIGH GLOSSY PVC/PET/PP, but also Acylic sheet, CPL, HPL, Aluminium /steel sheet, Venneer .

EmailMore

These production lines are specialize in sticking the decorating paper or PVC on the MDF, chipboards and plywood for producing panel of furniture which high efficient capability and pressure create a smoothly excellent surface of the finished product. It‘s your idea equipment of plywood & furniture company

EmailMore

1. Surface energy improvement Principle: Plasma is generated on the surface of materials through high-voltage corona discharge, causing the surface molecules of materials (such as plastics, films, metal foils, etc.) to polarize or introduce oxygen-containing polar groups (such as -OH, -COOH). Effect: Reduces the contact Angle, enhances wettability, and makes it easier for inks, adhesives or coatings to adhere. 2. Cleaning and activation Removing contaminants: Halo discharge can decompose weak boundary layers such as surface grease and dust. Microscopic roughening: Forming tiny etches at the nanoscale to enhance mechanical interlocking capabilities

EmailMore

HY-PUR1400A adopts advanced technology and precise mechanical structure to accurately laminate PUR rolls on different substrates. A wide variety of materials can be used, such as common wood, metal and plastic sheets as substrates, while PUR rolls include various types of decorative paper, PET, PP, PVC, CPL films, etc. Through dusting, heating, gluing, pressing and other processes, the coil and the substrate are tightly combined, with the advantages of strong bonding and flat fit, etc. It is widely used in many fields such as furniture manufacturing, architectural decoration, automotive interior, etc., which effectively improves the aesthetics and durability of the products and meets the diversified market demands.

EmailMore

This is a laminating production line, with the corona machine to use better, 1. Corona treatment to make the material surface activity enhancement, reduce the bubble generation, improve the lamination precision, so that the lamination is more flat 2. Can change the surface properties of some difficult to fit the material, so that the flat laminating machine can be processed more different material combinations.

EmailMore