Introduction

In today's competitive furniture manufacturing industry, efficiency and precision in acrylic processing have become critical success factors. Our company has developed an integrated solution combining an advanced acrylic laminating machine with a high-capacity acrylic cutting machine, creating a seamless production line for PVC film-coated acrylic sheet processing. This innovative system addresses multiple pain points in traditional acrylic fabrication methods.

The Challenges of Traditional Acrylic Processing

Conventional acrylic fabrication involves two separate, inefficient processes:

Lamination using outdated equipment

Cutting with limited-capacity tools

Most manufacturers still rely on pneumatic cutters that:

• Process just one acrylic sheet at a time

• Handle maximum 1.2mm thickness

• Require frequent operator intervention

• Produce inconsistent edge quality

These limitations result in:

Production bottlenecks

High material waste (up to 15% from edge defects)

Labor-intensive operations

Quality inconsistencies

Our Integrated Solution

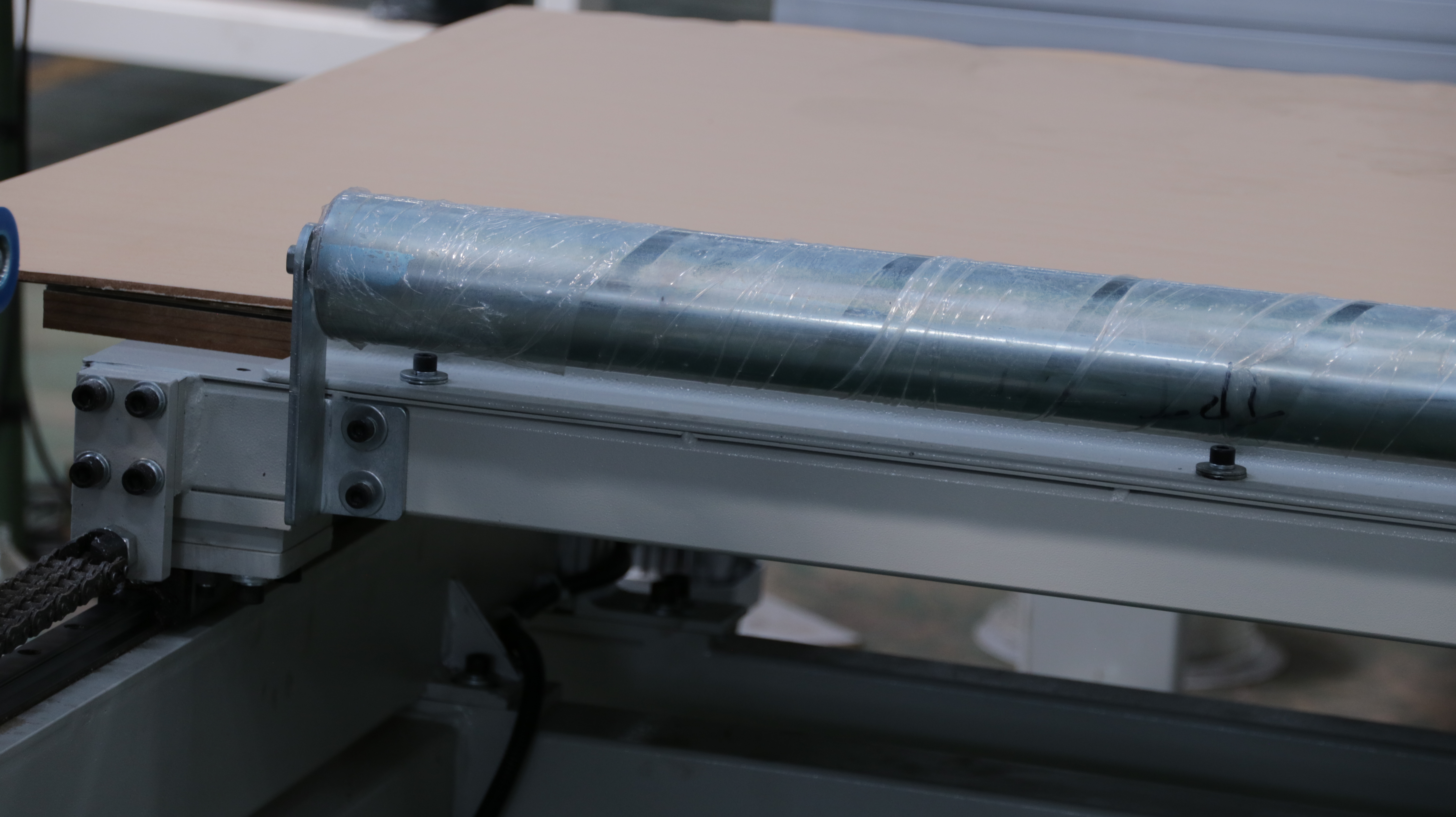

1. The Acrylic Laminating Machine

The first stage of our system features an automated acrylic laminating machine that applies PVC film with unmatched precision. Key advantages include:

• Uniform adhesive application

• Bubble-free bonding

• Precision alignment system

• Temperature-controlled rollers

• 30% faster than conventional laminators

This machine prepares acrylic sheets for subsequent processing by creating perfectly laminated substrates ready for cutting.

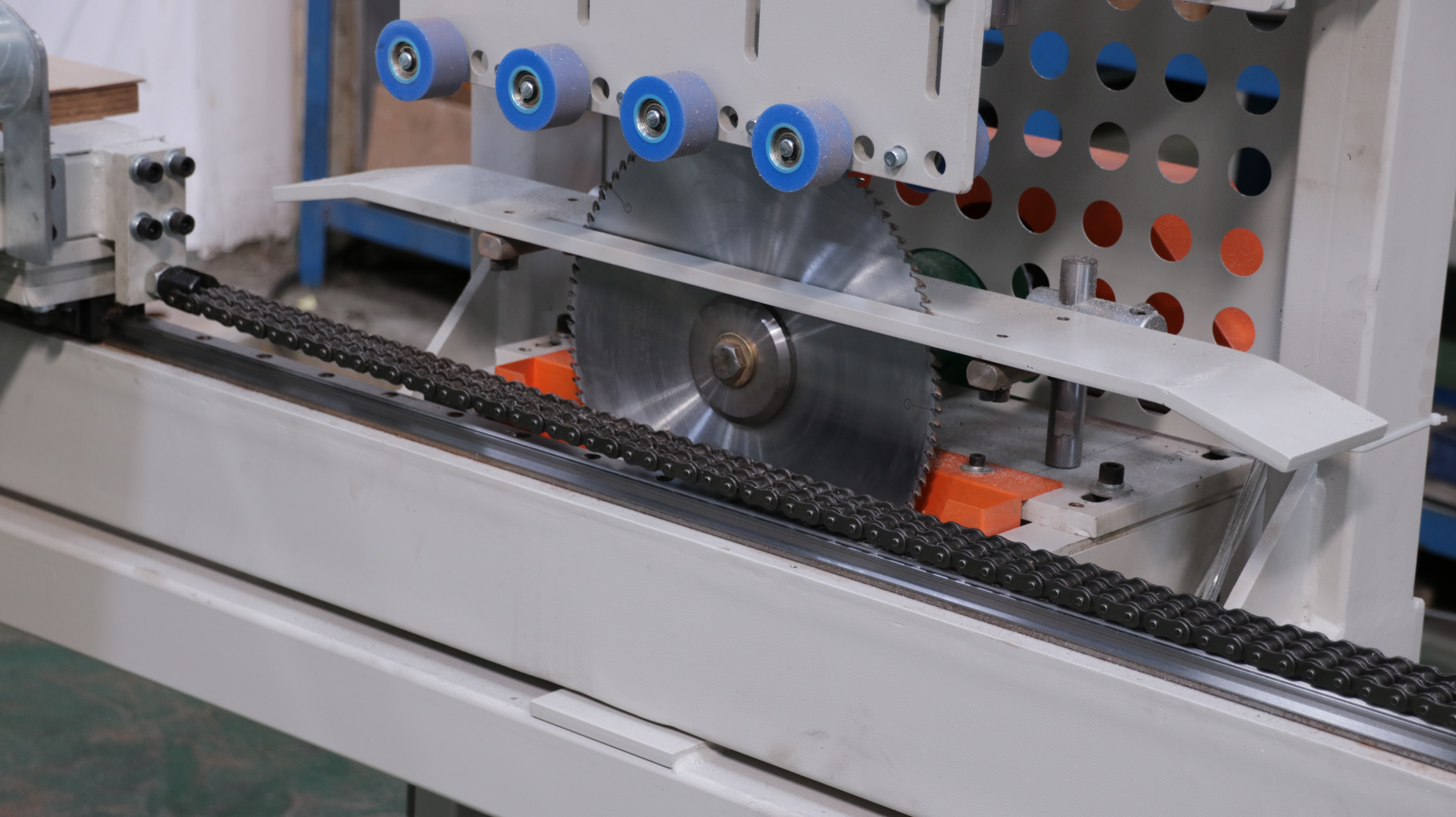

2. The High-Capacity Acrylic Cutting Machine

The second stage features our revolutionary acrylic cutting machine that redefines production efficiency:

• Processes 50 sheets of 1mm acrylic sheet simultaneously

• Converts 1.22×2.47/2.5m panels to standard 1.22×2.44m

• Maintains precision across entire stacks

• 5-6× faster than single-sheet cutters

• Reduces edge defects by 90%

Technical Specifications

| Parameter | Traditional Cutter | Our Machine |

|---|---|---|

| Capacity | 1 sheet | 50 sheets |

| Max Thickness | 1.2mm | 3mm (stacked) |

| Daily Output | 200 sheets | 1,200 sheets |

| Positioning Accuracy | ±2mm | ±0.5mm |

| Operator Required | Constant monitoring | Minimal supervision |

System Integration Benefits

The combination of our acrylic laminating machine and acrylic cutting machine creates unparalleled synergies:

Continuous Workflow

Automatic transfer from lamination to cutting

No intermediate handling

Consistent quality throughout

Material Optimization

Minimized PVC film waste

Reduced acrylic sheet edge trimmings

Higher yield from raw materials

Labor Efficiency

60% reduction in manual handling

One operator can manage both machines

Lower training requirements

Applications in Furniture Manufacturing

Our complete system excels in multiple furniture production applications:

Cabinet Components

Perfect for high-gloss PVC film finishes

Mass production of door panels

Consistent sizing for modular systems

Decorative Surfaces

Flawless edges for visible components

Efficient processing of laminated acrylic sheets

Custom sizing capabilities

Retail Fixtures

High-volume production capacity

Premium edge quality for display items

Durable PVC film surfaces

Economic Advantages

The financial benefits of our integrated system are substantial:

Capital Efficiency

Replaces multiple standalone machines

Lower total investment than separate units

Smaller footprint than conventional setups

Operational Savings

Energy consumption reduced by 25%

40% less floor space required

Lower maintenance costs

Return on Investment

Typical payback period: 8-12 months

Increased production capacity

Higher quality output commands premium pricing

Quality Improvements

Beyond efficiency gains, our system delivers superior quality:

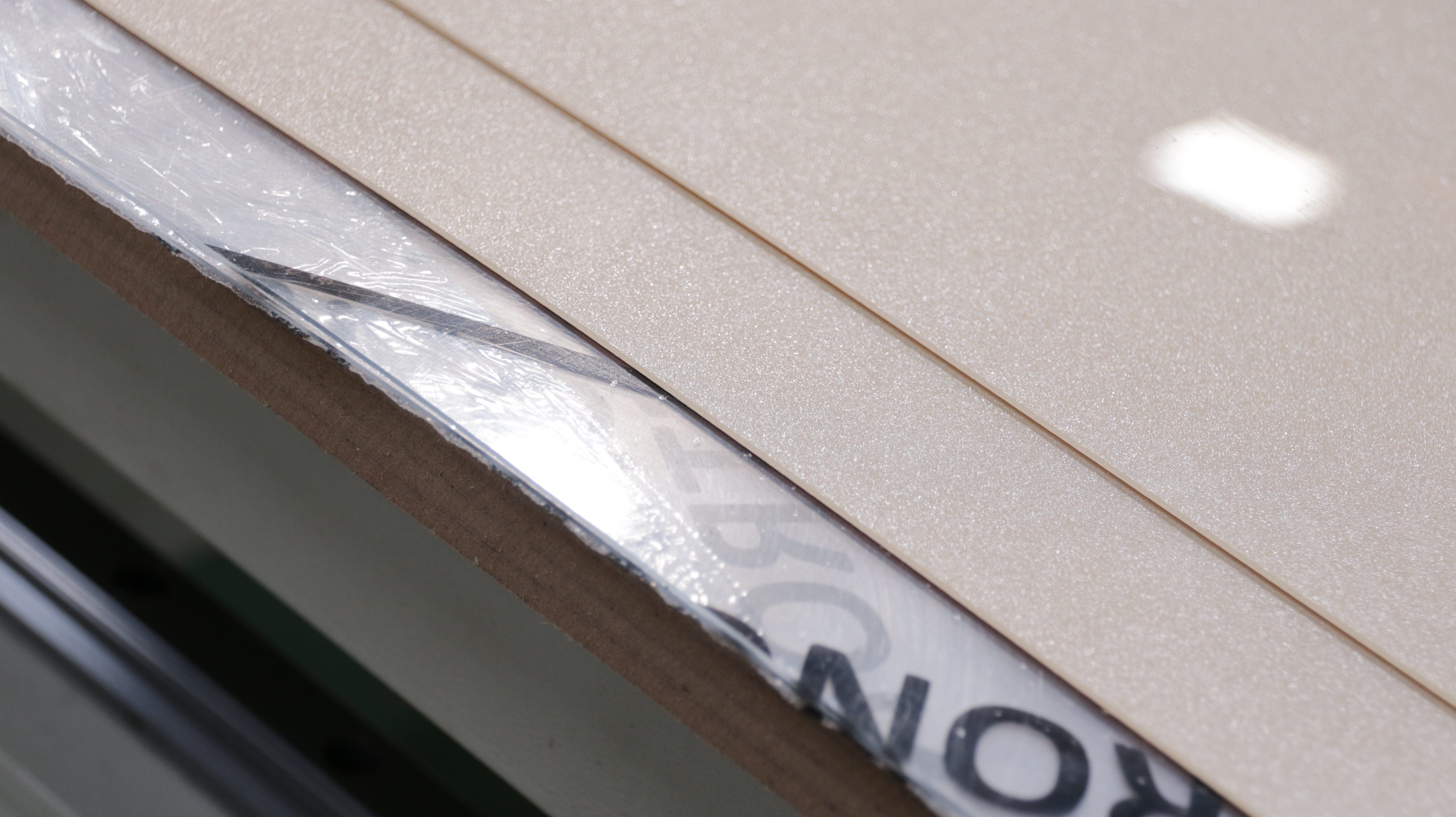

Edge Finish

Mirror-smooth cutting surface

No chipping or cracking

Consistent across entire batch

Dimensional Accuracy

±0.3mm tolerance maintained

Perfectly square edges

Uniformity across production runs

Surface Protection

PVC film remains undamaged

No scoring or scratching

Pristine final appearance

Industry Impact

Since its introduction, our system has:

• Been adopted by 3 major furniture manufacturers

• Processed over 500,000 acrylic sheets

• Saved an estimated 15,000 labor hours

• Reduced material waste by 120 tons annually

Future Developments

We continue to enhance our technology with:

AI-assisted quality control

IoT-enabled performance monitoring

Automated material handling options

Expanded size capabilities

Conclusion

Our integrated acrylic laminating machine and acrylic cutting machine system represents the future of acrylic sheet and PVC film processing. By combining lamination and precision cutting into one efficient workflow, we deliver:

Unmatched productivity

Superior quality

Significant cost savings

Operational simplicity

For furniture manufacturers seeking to upgrade their acrylic fabrication capabilities, our complete solution offers the perfect balance of performance and value. Contact us today to revolutionize your production process.