The full name and meaning of CPL

Full English name: Continuous Pressure Laminate

What is CPL?

CPL is a decorative laminated material manufactured through a continuous production process. It is a kind of

roll material and has the following characteristics:

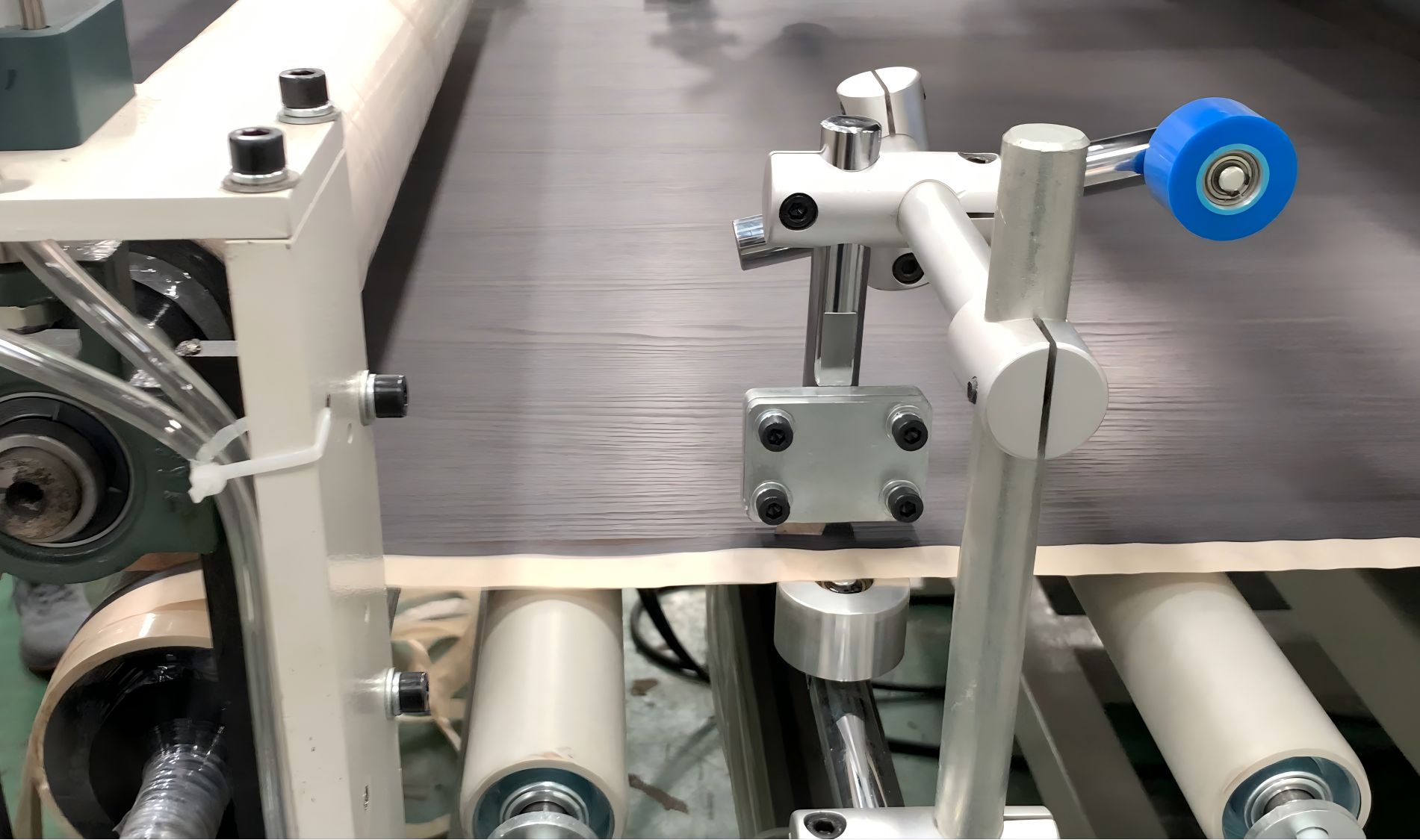

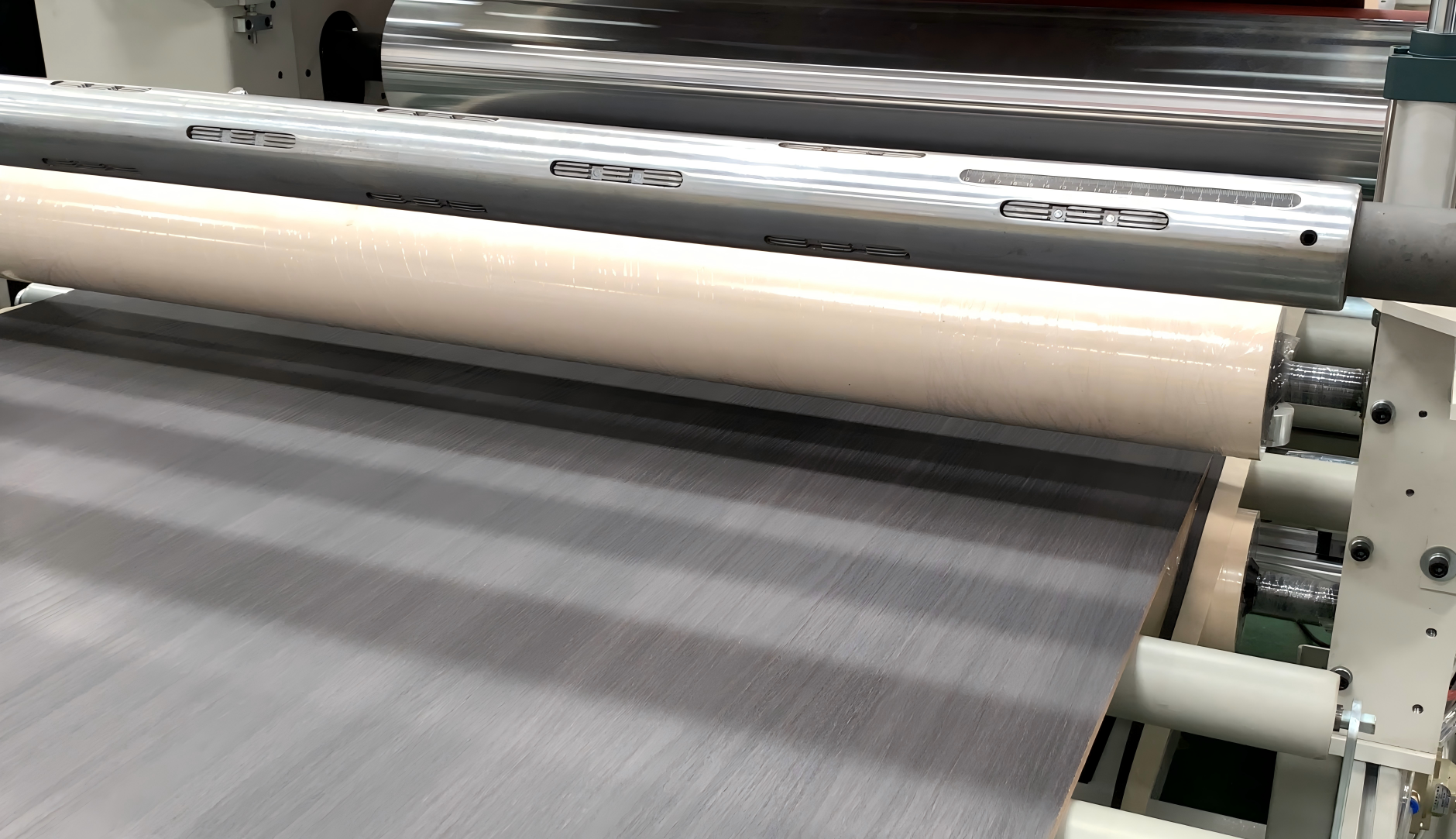

Production process: Its manufacturing process is similar to papermaking. After impregnating decorative paper

and melamine resin, it is pressed and cured through a continuously operating high-temperature and high-pressure

drum to form a continuous roll-shaped material. This is different from the single-piece pressed HPL (high-pressure

decorative board).

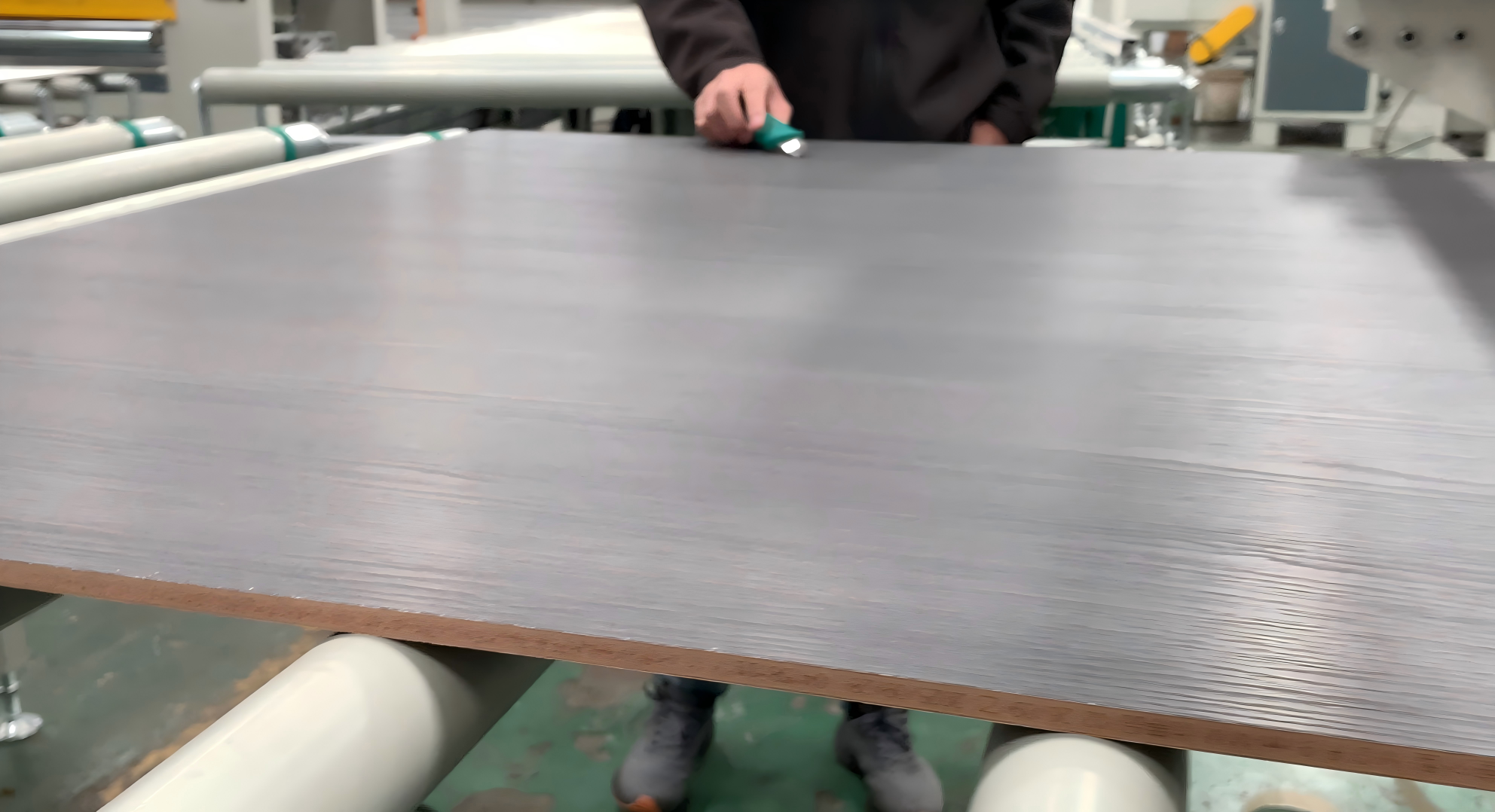

Physical properties: Generally, it is relatively thin (about 0.15-0.6 millimeters), soft in texture and can be rolled up.

Main use: Mainly used for covering. It is adhered to the edge or surface of the base material (such as particleboard,

medium-density fiberboard MDF), and is widely used in the edge banding of cabinets, wardrobes, office furniture

and the decorative surface of door panels.

The differences between CPL, HPL and PVC films

For a better understanding, it can be compared with common materials:

| Characteristics | CPL (Continuous Pressure Laminate) | HPL (High Pressure Laminate) | PVC Film (Polyvinyl Chloride Film) |

| Form | Roll Material | Hard Sheet Material | Roll Material |

| Flexibility | Good, bendable | rigid, non-bendable | Excellent, very soft |

| Main applications | edge banding, interior door panels | horizontal countertops, counters, surfaces requiring high wear resistance | soft furniture, light-load surfaces |

A Brief Summary

CPL can be regarded as the thin sheet version of HPL. It inherits the excellent wear resistance, scratch resistance

and chemical corrosion resistance of HPL, but presents it in a more flexible form, making it highly suitable for

modern automated edge banding and coating production lines.

Compared with PVC film, CPL usually has higher hardness and wear resistance because it contains paper and

thermosetting resin, while PVC is a thermoplastic