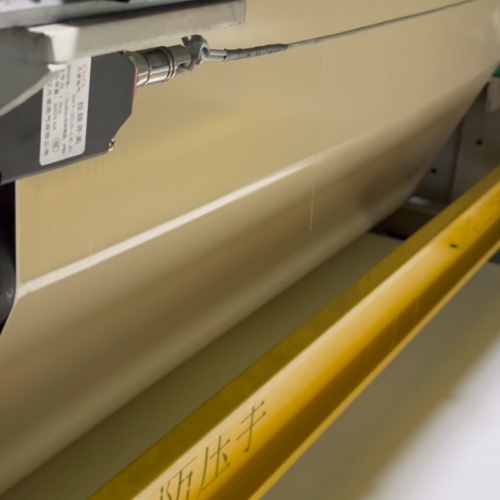

Large board wrapping machine is a kind of equipment specially used for surface wrapping processing

of large-size boards. It is widely used in furniture manufacturing, building decoration, automobile

interior and other industries. Below are some of the main features and functions of the Large Panel

Wrapping and laminatingMachine:

Main Features:

High efficiency:

The large board wrapping machine is able to complete the task of wrapping a large area

in a short time and improve the production efficiency.

Accuracy:

Adopting advanced control system to ensure the accuracy of the wrapping process and reduce

material waste.

Versatility:

It can handle a variety of different materials, such as PVC, wood grain paper, PET, etc., to adapt to the diversified market demand.

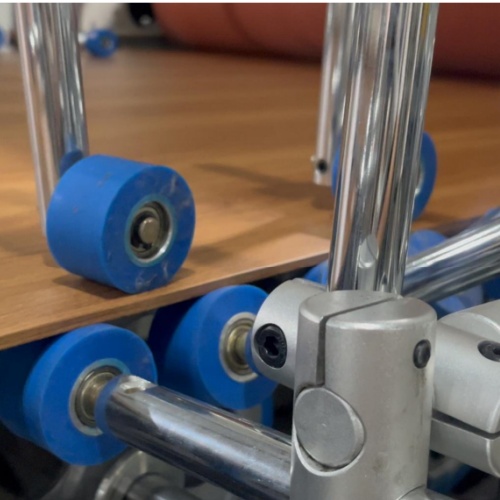

High degree of automation:

Many large board wrapping machines are equipped with automatic feeding, automatic cutting and other functions, which reduces manual operation and improves the automation level of the production line.

Strong adaptability:

Suitable for different thickness and size of boards with good flexibility.

Application Fields

Furniture manufacturing: used for wrapping table tops, cabinets and other furniture surfaces.

Building decoration: used for wrapping decorative materials for walls, ceilings, etc.

Automobile interior: used for surface treatment of interior parts such as doors and seats.

Precautions for operation

Regular maintenance: to ensure the normal operation of the equipment and prolong the service life.

Safe operation: operators need to be professionally trained to ensure safe use.

Material Selection: Select the suitable wrapping material according to the product demand to

achieve the best effect.

The introduction of the large plate wrapping machine greatly improves the production

efficiency and product quality, which is one of the indispensable equipments in the modern

manufacturing industry.