In the world of furniture manufacturing, cabinet making, and interior décor, the surface is everything. It's the first thing a customer sees and touches. Achieving a flawless, durable bond between a decorative layer (like PVC, veneer, or paper) and a substrate (like MDF, particleboard, or plywood) is a critical challenge. This is where PUR Panel Laminating Machines come in, representing a significant leap in technology over traditional hot melt adhesives.

What is a PUR Panel Laminating Machine?

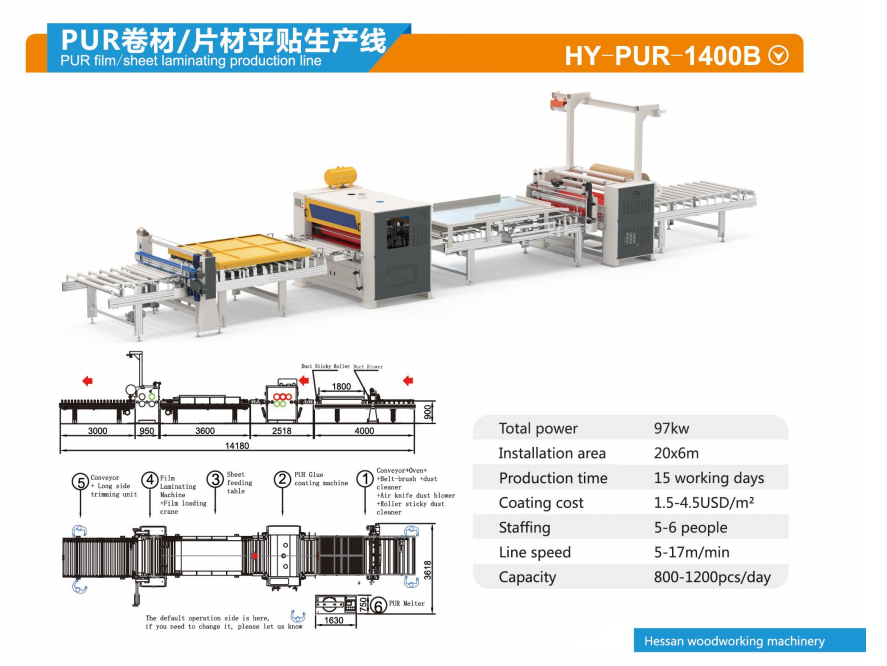

A PUR Panel Laminating Machine is an industrial system designed to automatically apply a reactive polyurethane (PUR) hot melt adhesive to securely bond a surface material to a panel. The machine typically consists of several key stations: a panel feeder, a precision glue applicator, a pressing section , and a cooling/output conveyor. Its core differentiator is the use of PUR adhesive.

The Game-Changer: PUR Adhesive

To understand the machine, you must understand the adhesive.

Traditional Hot Melt (EVA): Standard hot melts are thermoplastics. They melt when heated and re-solidify when cooled. While fast, they can be susceptible to heat and moisture, potentially leading to delamination over time.

PUR Hot Melt: PUR is a reactive adhesive. After it is applied as a hot liquid and solidifies upon cooling, it undergoes a secondary chemical reaction. It absorbs moisture from the air, causing it to "cure" and form irreversible cross-linked bonds. This process creates a powerful, permanent connection.

Key Advantages of PUR Laminating Machines

Exceptional Bond Strength & Durability: The cured PUR bond is incredibly strong and resistant to stress, making it ideal for demanding applications.

High Heat and Moisture Resistance: Products laminated with PUR can withstand extreme temperatures and high humidity without failing. This is crucial for kitchen cabinets, bathroom vanities, and outdoor furniture.

Superior Gap-Bridging Ability: PUR adhesive can fill minor imperfections and voids in the substrate, ensuring a consistent, bubble-free surface.

Excellent Chemical Resistance: The bond is resistant to many common solvents and cleaning agents, enhancing the product's lifespan.

Thinner Glue Lines: PUR achieves a strong bond with less adhesive, resulting in a cleaner finish and material savings.

Who Needs a PUR Laminating Machine?

This technology is essential for manufacturers who prioritize quality and longevity, including:

High-End Furniture and Cabinet Makers

Producers of Kitchen and Bathroom Cabinetry

Manufacturers of Office and Commercial Furniture

Companies producing flooring, doors, and wall panels

Conclusion

Investing in a PUR Panel Laminating Machine is not just an upgrade to your equipment; it's an investment in your product's reputation. By delivering a bond that is virtually indestructible under normal conditions, you can offer your customers unparalleled quality and durability. In a competitive market, this technological edge can be the defining factor that sets your brand apart.