How to use honeycomb laminating line to press honeycomb door panels

To press the honeycomb door panels with honeycomb laminating line, you can follow the steps below:

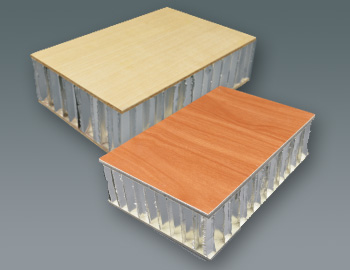

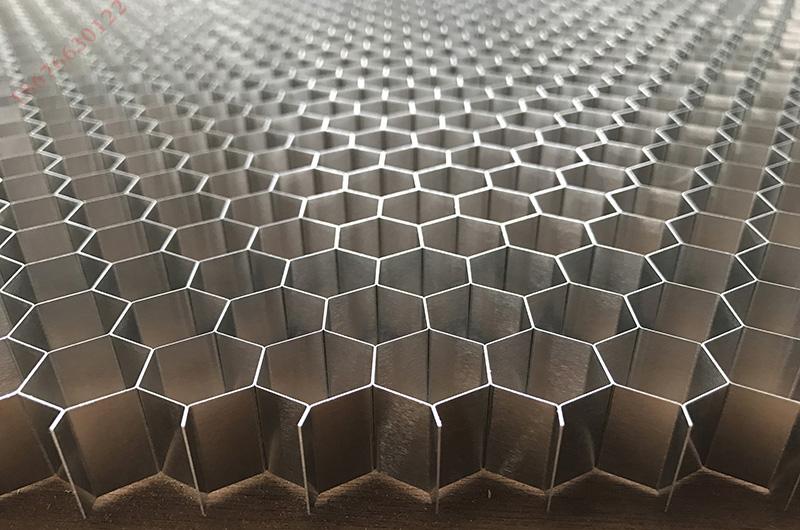

1. Prepare materials: Get the required honeycomb core board and panel materials. Honeycomb core board is usually made of honeycomb paper or aluminum honeycomb board, while the panel material can be wood, plywood, density board, etc.

2. Prepare the honeycomb laminating line: Ensure that the equipment and tools for the honeycomb laminating line are complete and in proper working condition. This includes honeycomb laminating machine, pressing machine, cutting machine, etc.

3. Prepare door panels: Cut the panel material to the appropriate size to fit the honeycomb core panel according to the required size and specification.

4. Preparing honeycomb core boards: Cutting honeycomb core boards to the same size as the panel material.

5. Apply glue: Apply glue evenly on one side of the panel material. This can be a suitable glue suitable for honeycomb lamination, such as polyurethane glue.

6. Press-fit: Place the glued panel material and honeycomb core board on the table of the honeycomb laminator. Make sure they are aligned and fit tightly. Then, place them in the press-fit machine and apply the proper pressure and temperature to glue them together. This process may take some time to ensure that the glue is fully cured.

7. Cutting and trimming: The pressed honeycomb door panels are removed from the press and cut into the desired size and shape using a cutter or other appropriate tool. The door panels are then trimmed so that the edges are flat and smooth.

8. INSPECTION AND QUALITY CONTROL: The quality and appearance of the door panels are inspected to ensure that they meet the requirements. If there are any defects or unqualified parts, they need to be repaired or replaced.

These are the basic steps for pressing honeycomb door panels using honeycomb composite production line. It is recommended to use Hessan Woodworking Machinery PUR adhesive honeycomb panel and door panel pressing production line, which is mainly used for honeycomb panel laminating, using PUR reactive hot melt adhesive, the whole line is equipped with a feeding table, dust remover, adhesive coating on the board, pressing platform, and the boards, after the laminating of the boards, will be pressed through the 6-meter rollers on-line successively. The production speed of this line is fast, eliminating the need for long time pressurization during the transmission of water glue lamination. It is suitable for all kinds of flat simple doors, thick plate furniture and other applications. It is the best choice to improve the new technology and save energy.

Applicable materials

Surface material: medium fiberboard, particle board, fireproof board

Substrate: Paper honeycomb with frame, Foam board

Glue: PUR reactive hot melt adhesive

Workflow:

1.Unloading table

2.Conveyor platform (one or two persons to feed the boards, depending on the size and weight of the boards)

3.Dust remover (to clear the surface particles or dust)

4. Drying tunnel (preheat the board, keep the glue open time, according to the characteristics of the glue to choose to use or not)

5. Single-side gluing machine (using ceramic rollers to control the glue, silicone rollers for coating, adjustable glue volume, uniform coating)

6. Artificial laminating platform (the operator puts the border and paper honeycomb on the board after gluing, and then puts another board after gluing to cover it in reverse, and sends it to the successive roller presses)

7. Roller press (total length 6 meters, through the encrypted roller, under the pallet for the belt conveyor, the three layers of material smooth pressurization. 6 meters of conveyor rows, can extend the press time as well as the frequency of boards.)

8.Discharging platform (manual lifting)

9.Stacking platform (finished product stacking)