In woodworking, furniture manufacturing, and decorative panel production, achieving a flawless surface finish is critical. Before applying PUR (Polyurethane Reactive) hot-melt adhesive in flat lamination processes, any dust or debris on the substrate can lead to poor adhesion, bubbling, or delamination. To ensure optimal bonding, double-sided dust removal systems equipped with sisal brushes are widely used.

PUR adhesives are known for their strong bonding, moisture resistance, and durability. However, their performance heavily depends on surface cleanliness. Even microscopic dust particles can:

Reduce adhesive penetration, weakening the bond.

Cause air entrapment, leading to bubbles or blisters.

Result in uneven surfaces, affecting the final product’s aesthetics.

Traditional dust removal methods may not be sufficient for fine particles. Sisal brushes, due to their natural fiber properties, provide superior dust removal without damaging delicate surfaces.

Sisal is a natural fiber derived from the Agave sisalana plant, known for its:

High abrasion resistance – Long-lasting durability.

Natural stiffness – Effective in dislodging embedded dust.

Non-static properties – Prevents dust re-attachment.

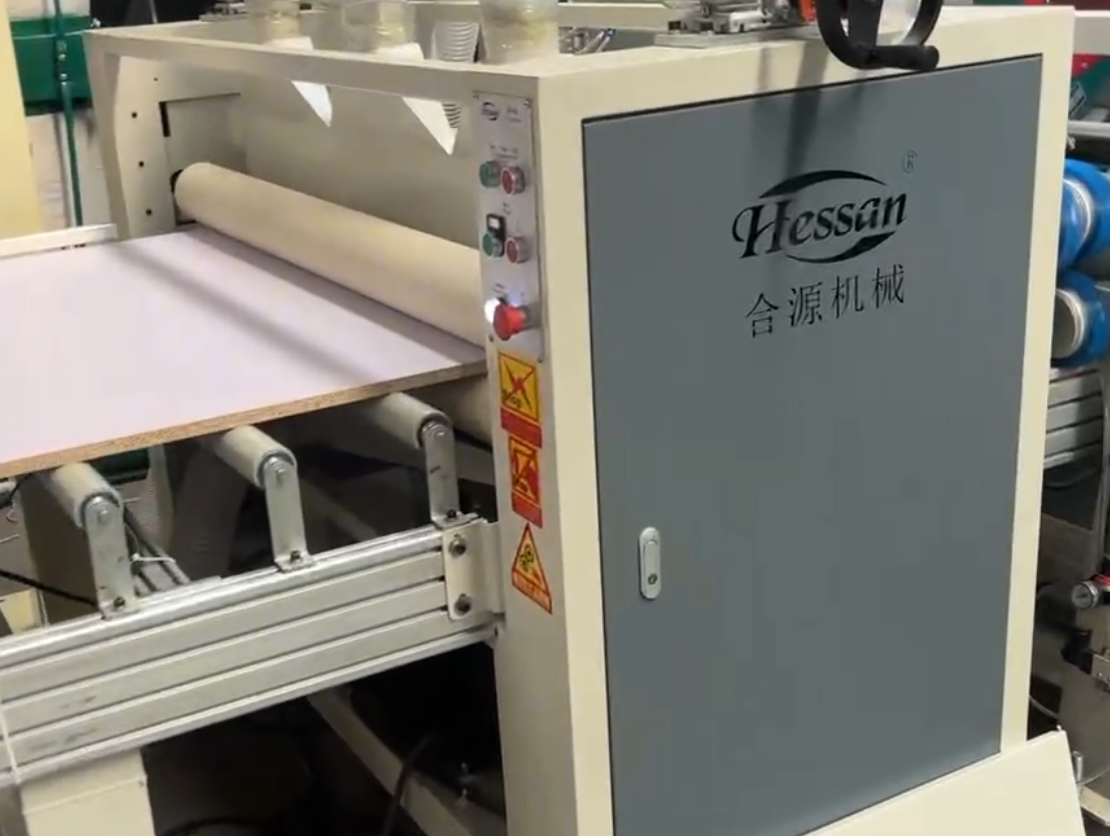

A double-sided sisal brush system consists of two rotating brushes (top and bottom) that clean both surfaces of the substrate (e.g., MDF, particleboard, or plywood) simultaneously before adhesive application.

How Does a Double-Sided Sisal Brush Dust Removal System Work?

Material Feeding – The panel enters the dust removal unit via a conveyor belt.

Brush Rotation – Motor-driven sisal brushes rotate at high speed (typically 800-1500 RPM).

Dust Dislodging – The stiff sisal fibers lift and eject dust from grooves and pores.

Exit & Lamination – The cleaned panel proceeds to the PUR adhesive applicator for bonding.

Key Components:

Sisal Brush Rollers (Top & Bottom) – Primary cleaning agents.

Adjustable Pressure System – Ensures optimal contact without damaging the substrate.

Advantages of Sisal Brushes for Double-Sided Dust Removal

Superior Dust Removal – Reaches deep into wood grain for thorough cleaning.

Gentle on Surfaces – Unlike metal brushes, sisal does not scratch delicate substrates.

Static-Free Cleaning – Prevents dust from reattaching to the panel.

Long Service Life – Sisal fibers resist wear, reducing replacement frequency.

Eco-Friendly – Natural fibers are biodegradable and non-toxic.

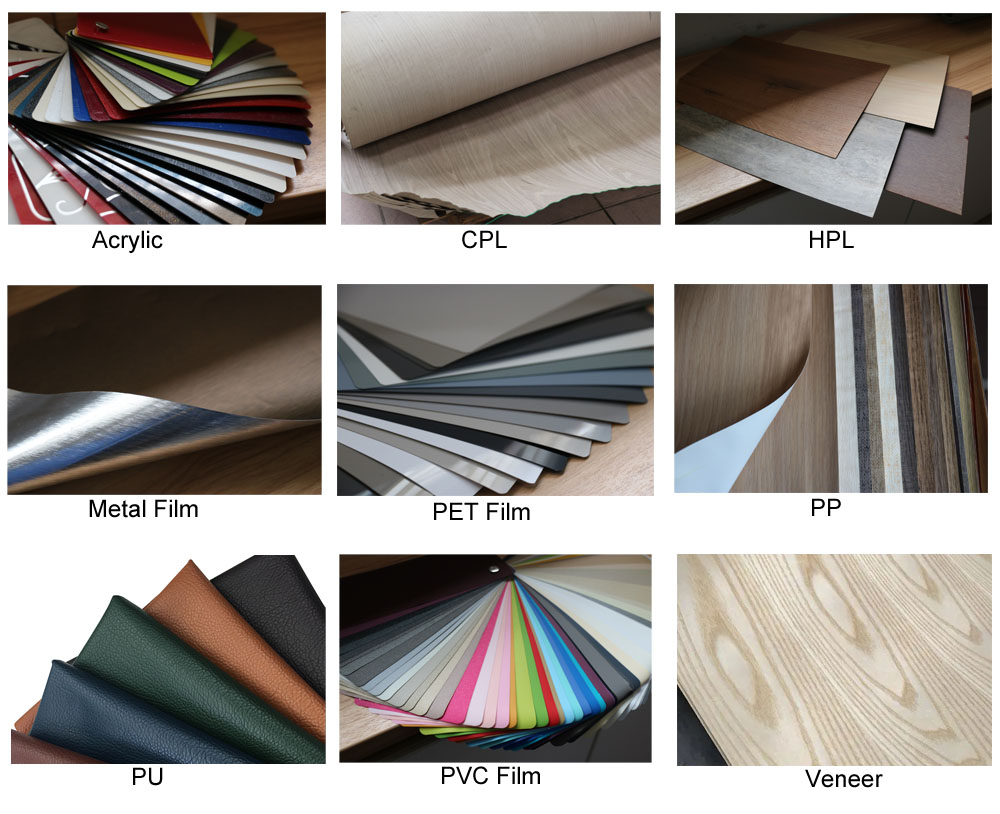

Applications in PUR Flat Lamination

Sisal brush dust removal systems are essential in:

Furniture Manufacturing – Ensures flawless veneer and laminate bonding.

Decorative Panels – Prepares MDF/HDF for high-gloss finishes.

Door & Window Production – Improves PUR adhesive performance for waterproof laminates.

Floor panel production – Cleans composite panels before adhesive application.

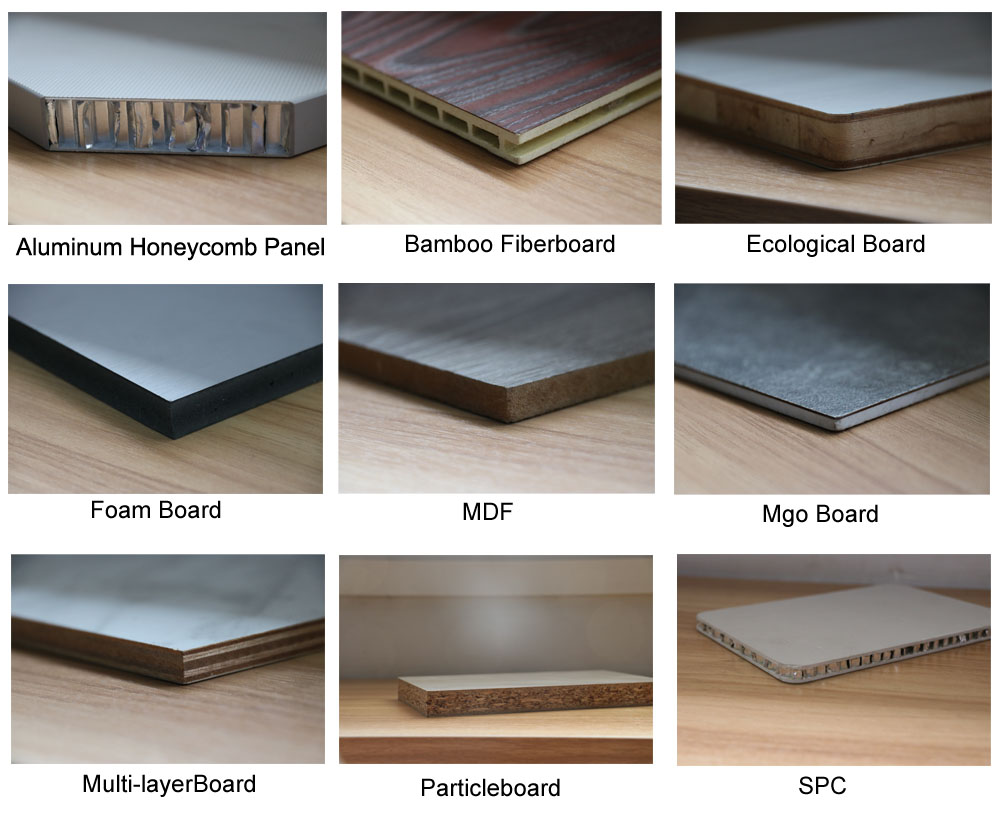

Material Plate

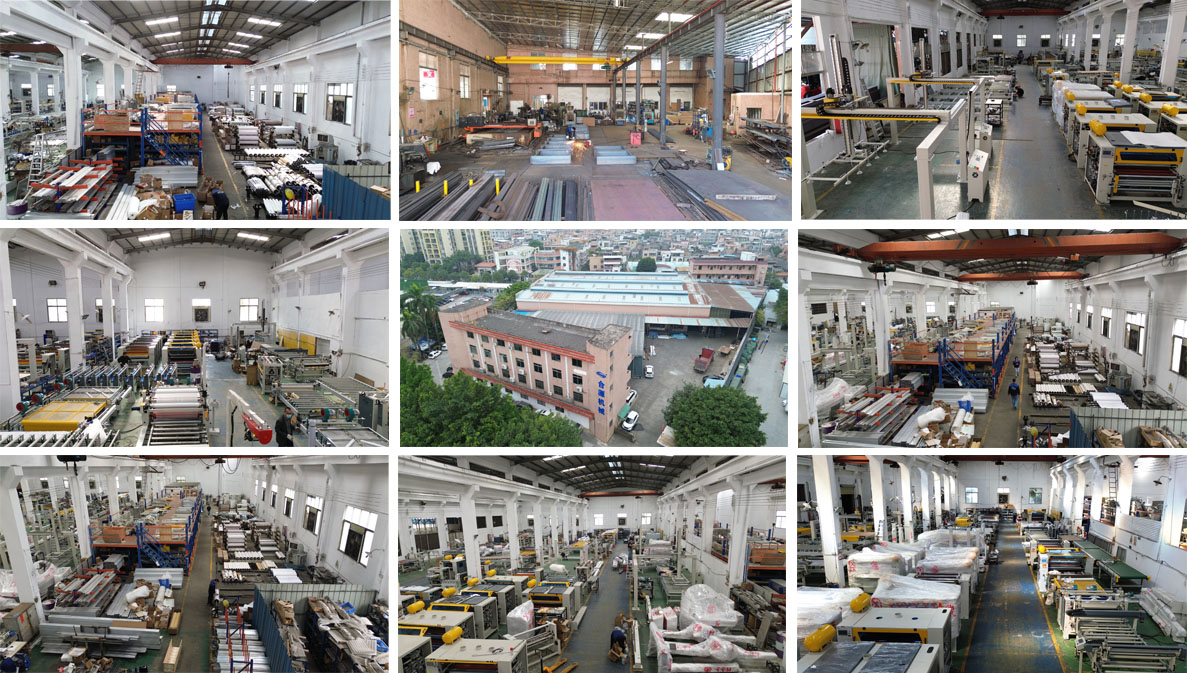

Our Factory

Company Certificate

Our Clients

Our Partners