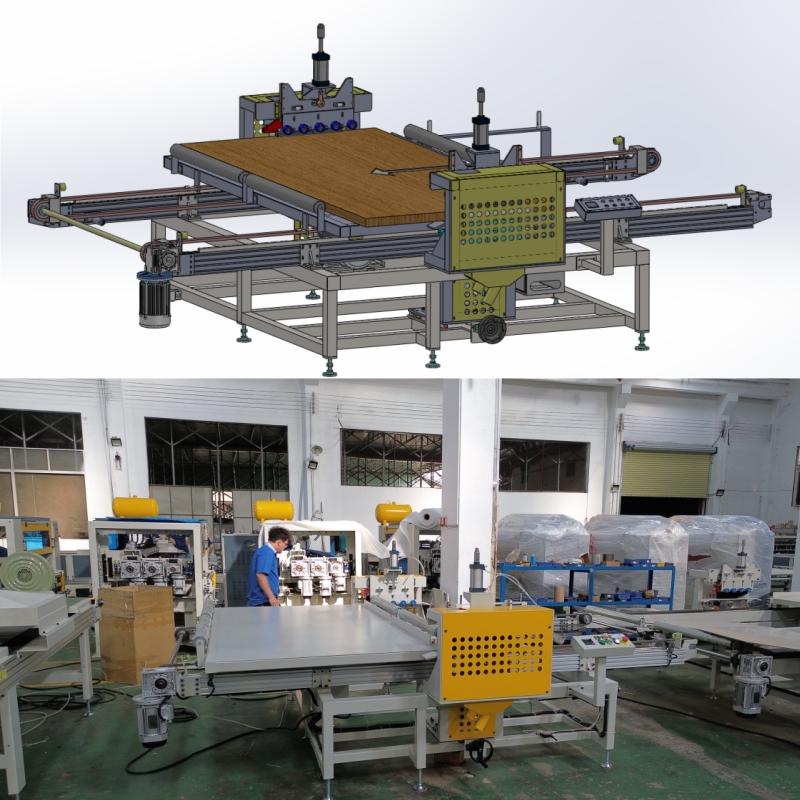

Acrylic edge sawing machine:

Advantageous features

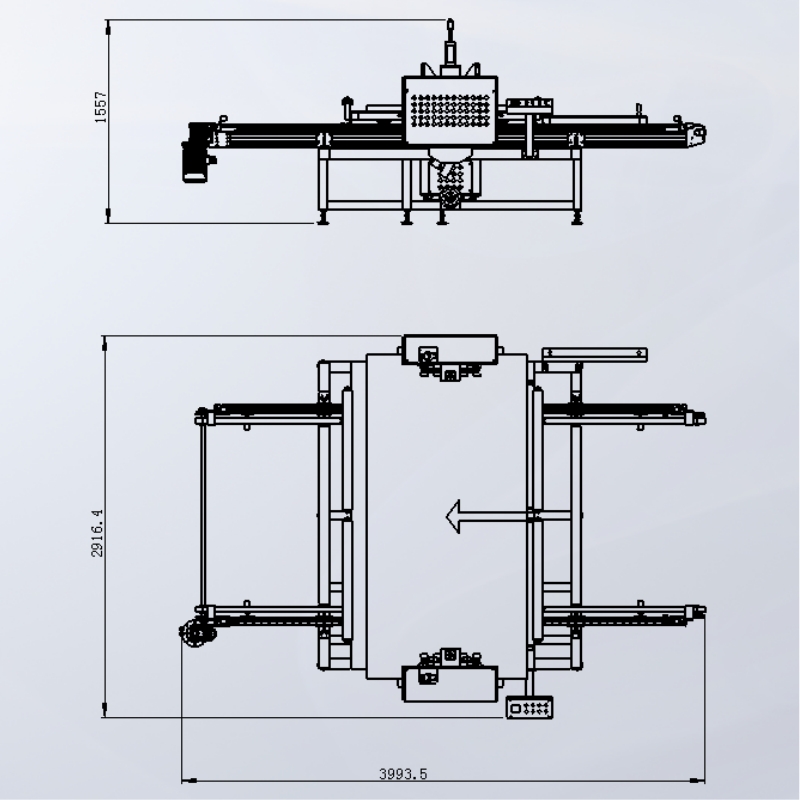

High precision: sensor and pneumatic platen control synergistically, accurate cutting size.

High efficiency and stability: dual motor division of labor, adapting to continuous mass production.

Safe and convenient: manual loading combined with automated cutting, reducing the risk of manual intervention.

Suitable for advertising decoration, display products and other acrylic processing industry, is the ideal equipment

to optimize the production process.

(Note: according to the actual demand for further supplemental technical parameters or customized features.)

Workflow

Manual loading: stack the acrylic boards on the working table.

Automatic conveyor: start the conveyor motor, chain drive to send the sheet to the sensor position.

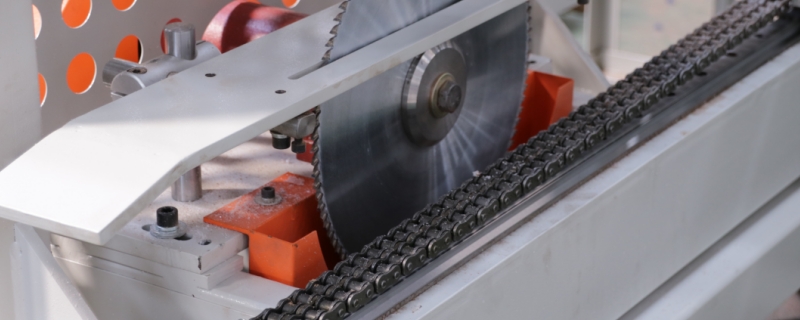

Pressure cutting: press down to fix the plate, electric sawing system synchronized to remove the short

side of the excess waste, to ensure that the edge is neat.

Core Configuration

Short edge sawing motor: double 4KW strong power, ensure the edge cutting fast and smooth, no burr.

Conveyor motor: 1.5KW drive, stable transmission of plates, with sensors to achieve accurate positioning

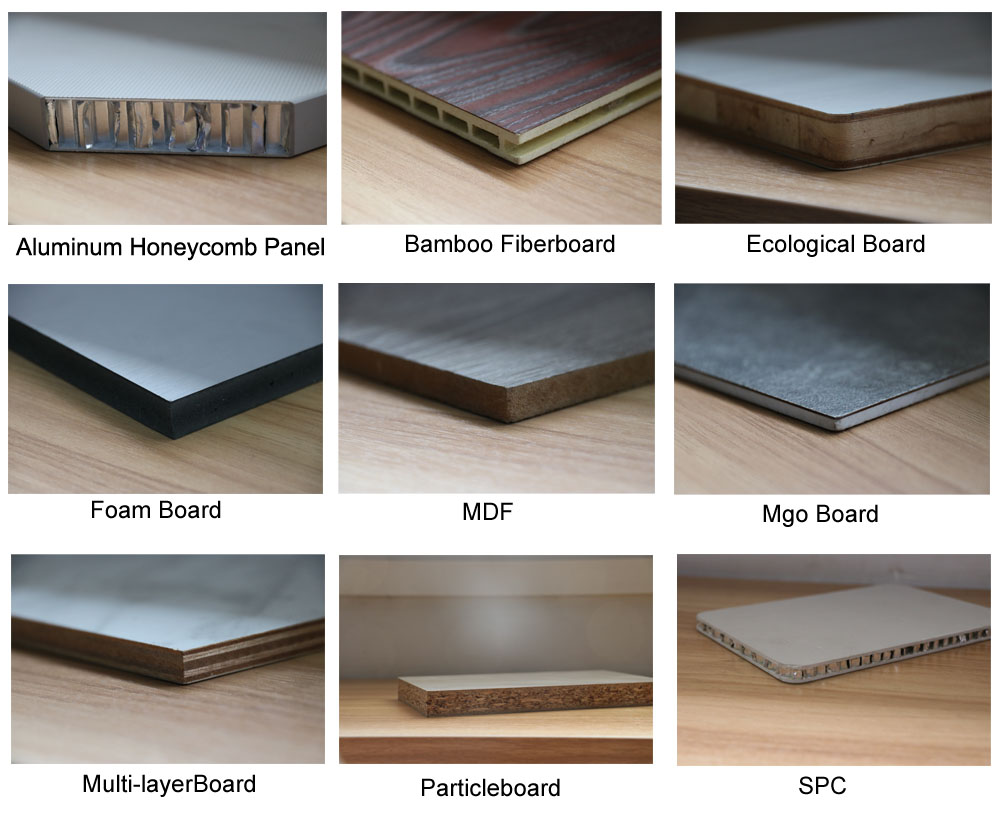

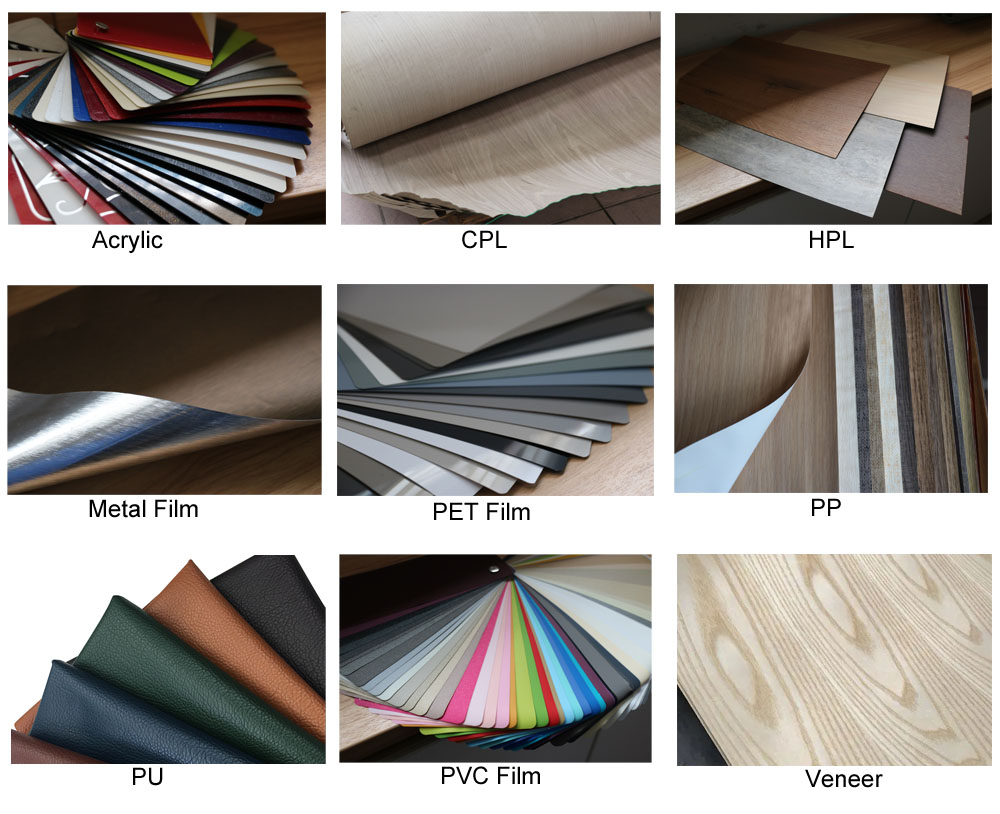

Material Plate

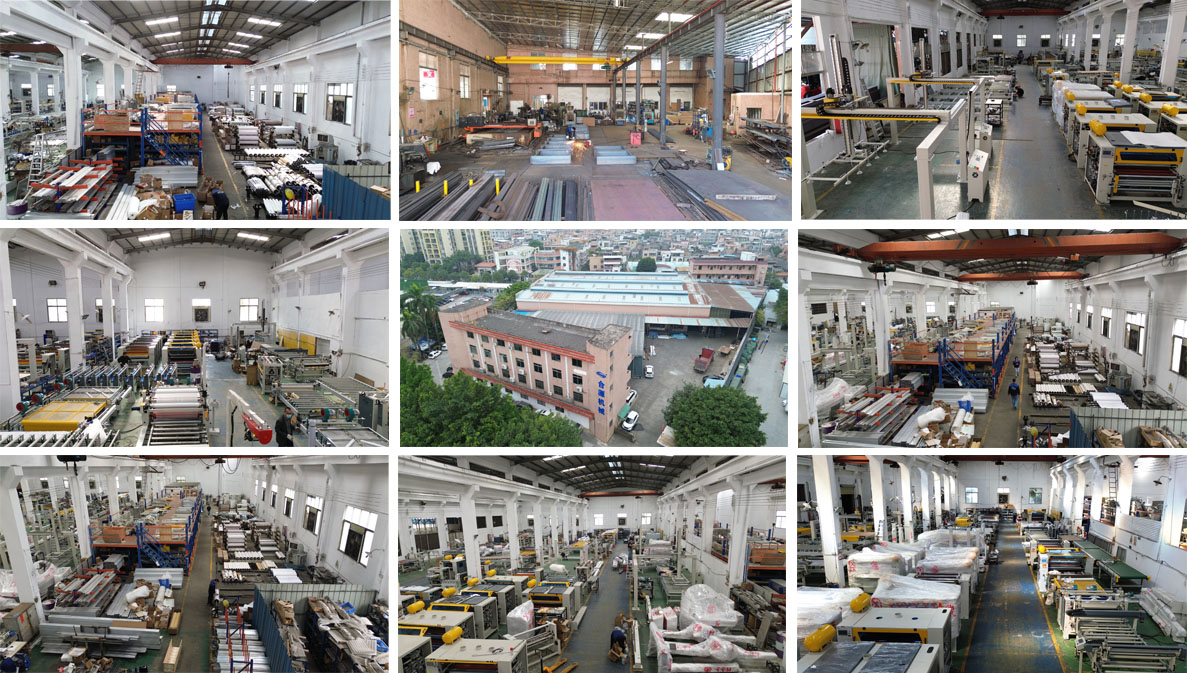

Our Factory

Company Certificate

Our Clients

Our Partners