Scope of application

1. Basic function: laminating high-grade PVC, PETG film, transfer film and other decorative materials.

2. Extended function: after adding silicone film, it can be laminated with leather, wall cloth or wood veneer and other decorative materials.

3. Application areas: interior doors, wardrobe doors, casement doors, bathroom cabinet doors, computer desks, office furniture and other door surfaces of the decorative production.

Technical characteristics

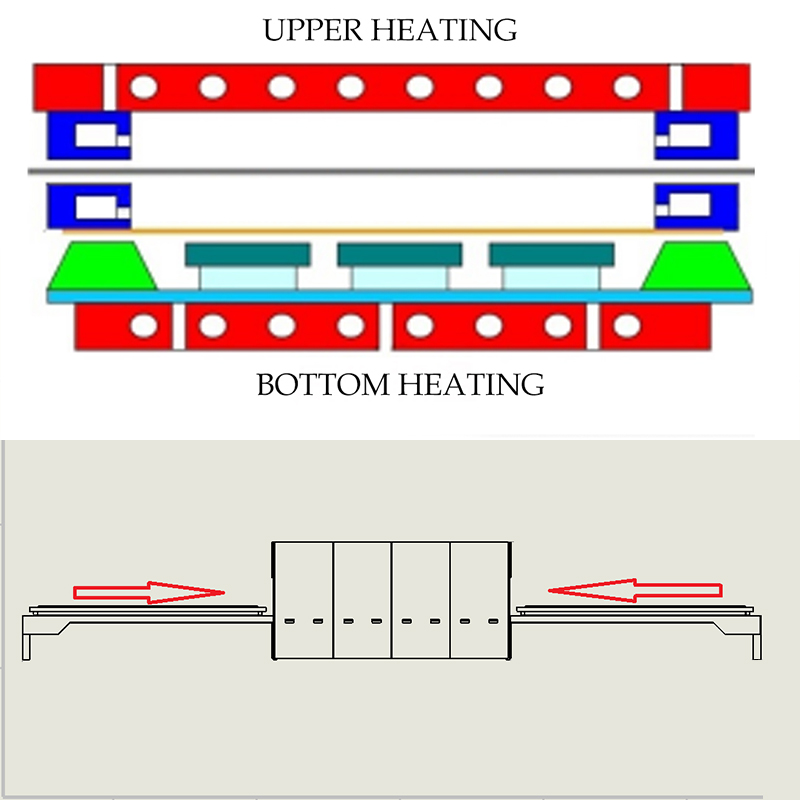

1. Infrared fast double heating: top and bottom synchronous heating, ensure the even heating of the sheet and film, improve the quality of wrapping.

2. Lifting heating box: adjust the heating area flexibly, adapt to different thickness of the board.

3. Aerogel heat insulation layer: super heat insulation and fireproof performance, reduce heat loss, energy saving effect is enhanced by more than 30%.

4. Automatic framing system: simplify the operation process, reduce manual intervention, and increase the efficiency greatly.

5. Fast film cutting device: two sets of automatic film cutting devices, saving manual film cutting time and reducing material waste.

6. High-speed vacuum pump (100m³/h) equipped with large vacuum tank, quickly reach the set pressure value, shorten the time of suction-coating and moulding, improve the production efficiency.

7. Frequency conversion speed control operation: prevent the board from shifting, shorten the running time and improve the working efficiency.

8. Cooling fan: introduce rapid cooling, fast shaping of boards, reduce the deformation of boards.

Core Advantage

1. Automatic dual-station design: the worktable can run continuously without waiting, and the automatic press frame saves time, which can maximise the working efficiency.

2.PLC control system: support multi-mode switching (low pressure/high pressure), preset parameters to adapt to different materials (e.g. PVC film ductility difference), adapt to all kinds of materials of PVC film and boards; fault alarm function, foresee faults in advance, easy to check and maintain.

3. Wide and narrow film universal worktable: After upgrading, it supports wide and narrow film universal (e.g. width 1400, 1250mm film material), no need to change the worktable or add the separator frame, more convenient for processing and wider range of use.

4. One-button operation: high degree of automation, easy to operate, suitable for zero-based workers, reducing labour costs.

Our Factory

Company Certificate

Our Clients

Our Partners