In the flooring and decorative panel industry, SPC (Stone Plastic Composite) and

WPC (Wood Plastic Composite) panels are widely used due to their durability, waterproof

properties, and cost-effectiveness. However, their non-porous, low-energy surfaces make adhesion

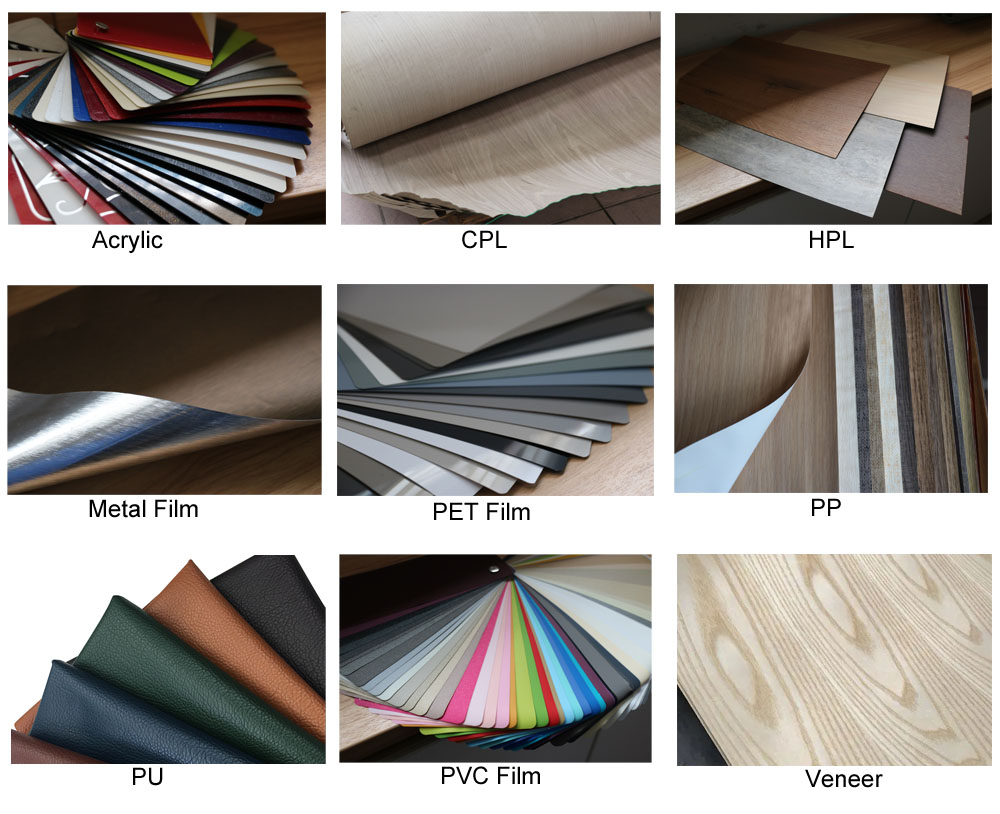

challenging, especially when using PUR (Polyurethane Reactive) hot-melt adhesives in flat lamination processes.

To ensure strong and long-lasting bonding, corona treatment machines are essential for modifying the

surface energy of SPC/WPC panels before lamination. This article explores the role of corona treatment

in PUR lamination, its working principle, benefits, and key considerations for selecting the right machine.

Why Corona Treatment is Necessary for SPC/WPC Panels?

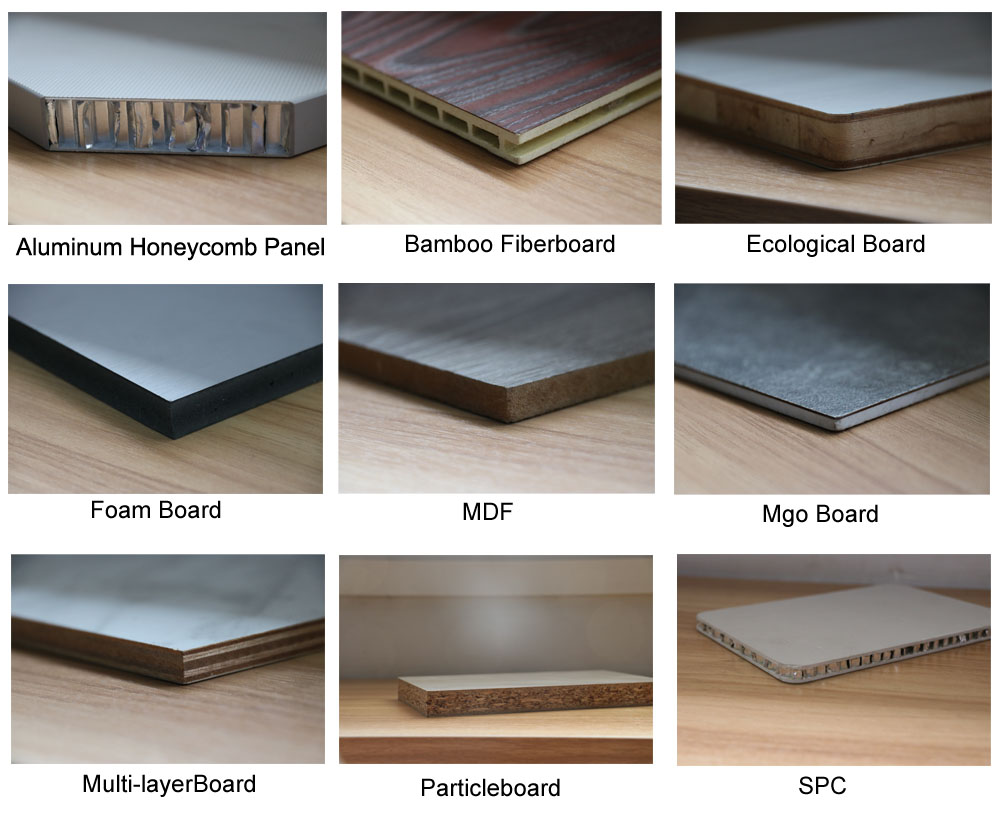

SPC and WPC panels consist of a blend of calcium carbonate, wood/plastic fibers, and polymer resins,

resulting in a smooth, low-surface-energy substrate.

Without proper surface treatment:

PUR adhesives may not wet the surface properly, leading to weak bonding.

Delamination can occur under stress or humidity.

Laminate layers (such as decorative films) may peel off over time.

Corona treatment oxidizes the surface, creating microscopic roughness and polar functional

groups that significantly improve adhesion.

The maximum output power of the halo host is 3KW

Power supply voltage: 220V

Electrode voltage: 12-15KV

Operating frequency: 15-20HZ

Main unit functions: main power switch, start, stop, power display, material passing speed display, power + and - adjustable at will, detection, automatic start and stop.

Detection protection: When the detected material stops moving, the machine will automatically shut down with an audible alarm.

Automatic start and stop: When the electric motion sensor is in operation and stops halfway, the high-voltage output of the electric motion sensor stops. If the material moves again, the high-voltage output of the electric motion sensor will automatically start

Manual operation is required.

Interlock protection: When the halo frame is not closed or opened during operation, high voltage is output. At this time, the operation start button is invalid, ensuring the safety of personnel and equipment

Over-temperature protection: When the temperature of the main rectifier power supply and the drive module is too high, the machine will automatically shut down for protection.

Transformer: Oil-immersed high-frequency high-voltage transformer

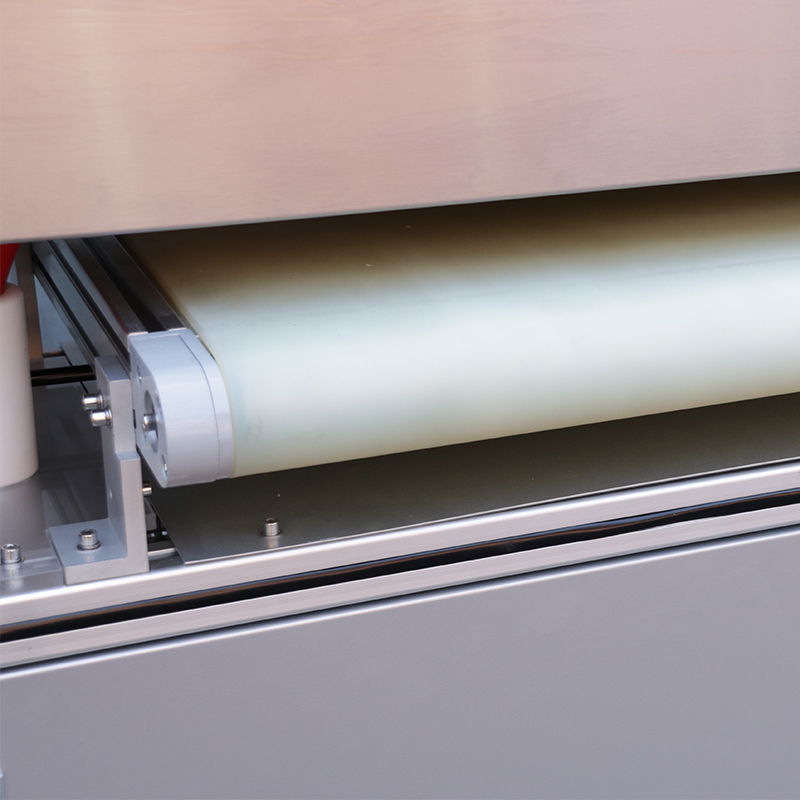

1. Halo frame: Closed stainless steel halo discharge frame, single-sided, top treatment, cylinder up and down opening and closing, effective treatment width: 1300mm

Main corona roller: Silicone rubber roller sleeve, diameter 100mm*1400mm (1 piece), material: aluminum, silicone

Guide rollers: 54mm*1400mm in diameter (2 pieces), material: iron, with rubber coating

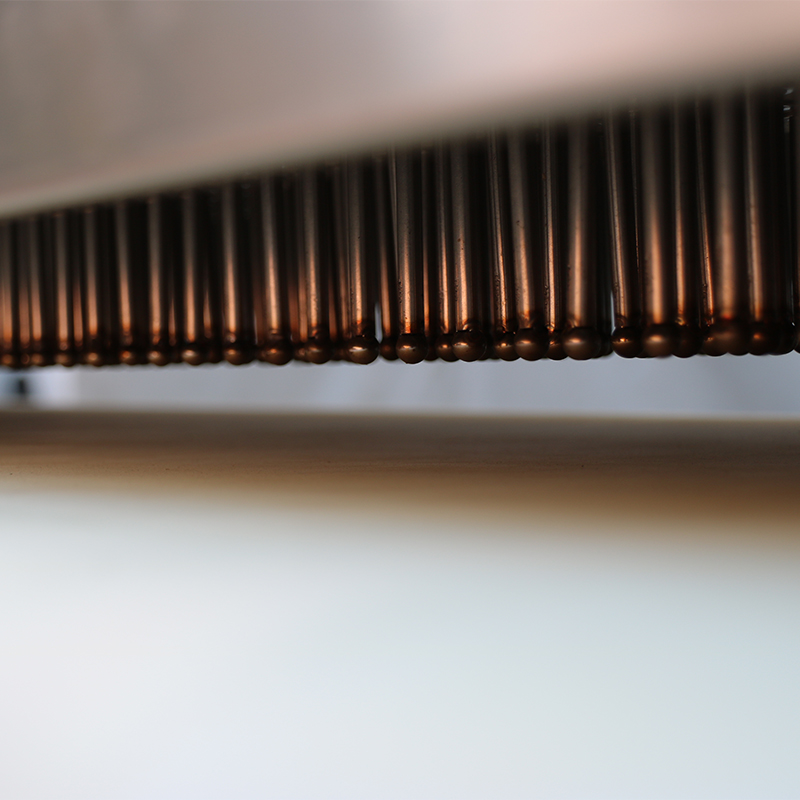

Discharge electrode: Four-tooth aluminum alloy discharge electrode (1 set)

Halo frame safety cover, wall panel, safety protection cover, material: iron

Material Plate

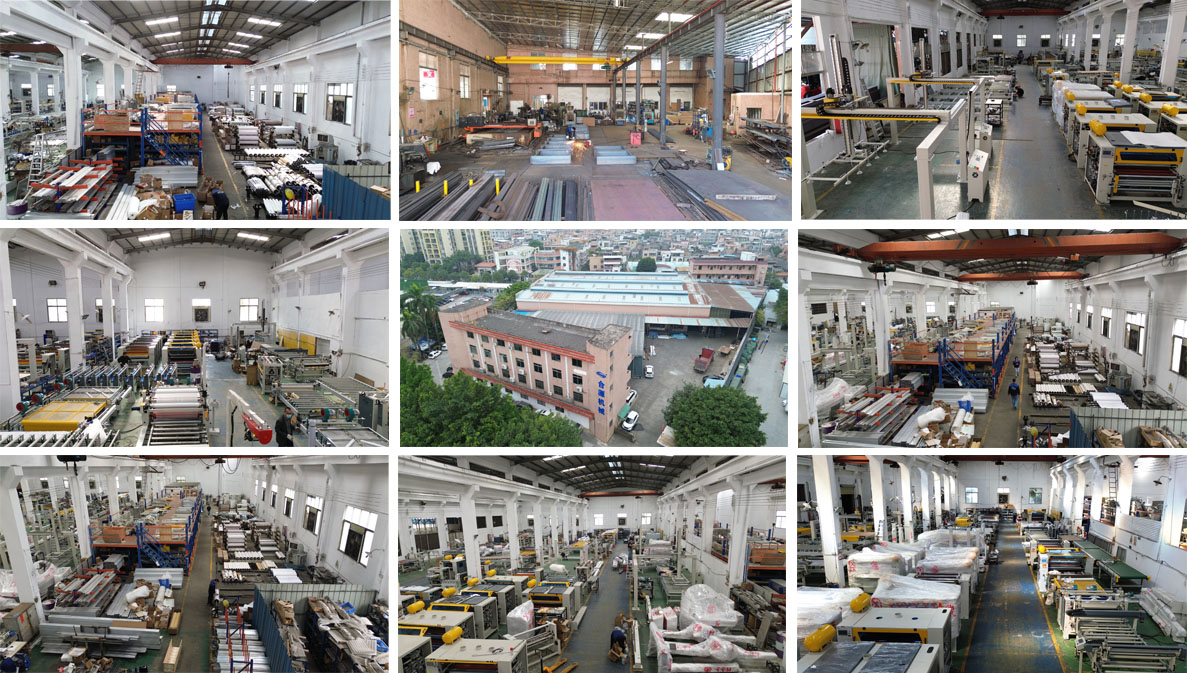

Our Factory

Company Certificate

Our Clients

Our Partners