Corona Treatment Machine for PVC Film: Enhancing Surface Adhesion for Superior Coating.

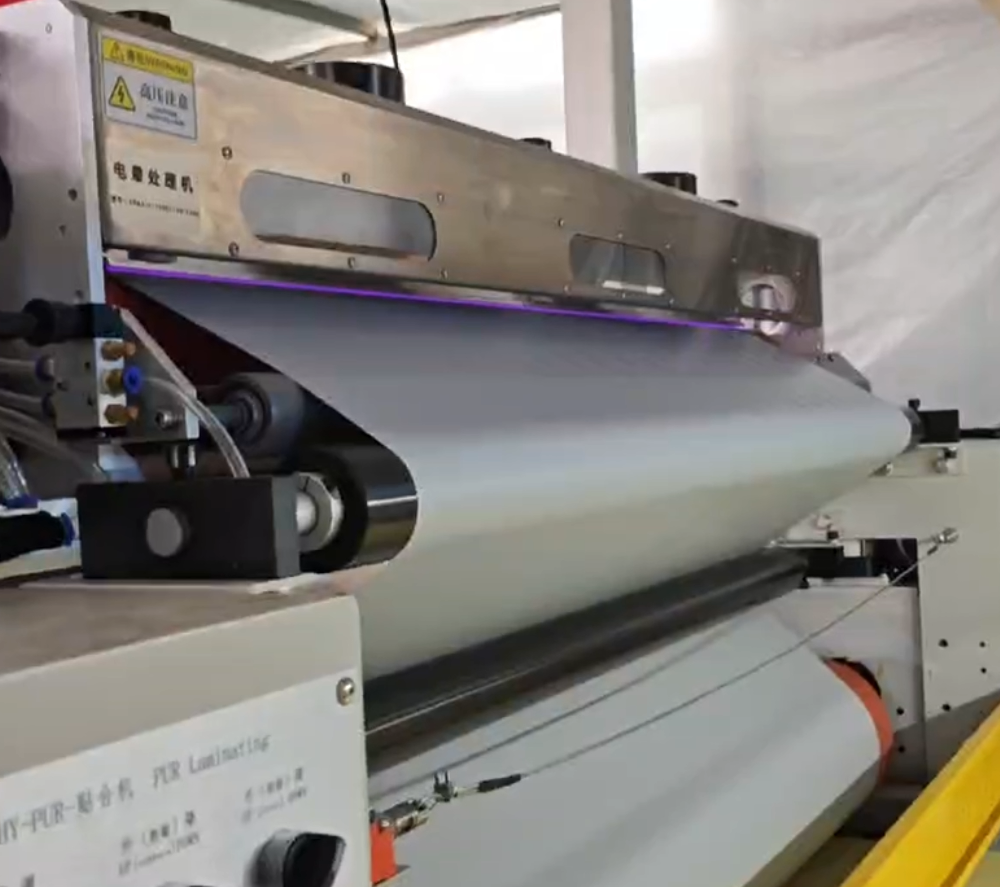

In the panel processing, PVC (Polyvinyl Chloride) film is widely used due to its durability, flexibility, and cost-effectiveness. However, one of the key challenges in working with PVC film is its inherently low surface energy, which makes it difficult for adhesives and coatings to adhere properly. To overcome this issue, Corona treatment machines are employed to modify the surface properties of PVC film, ensuring optimal adhesion for subsequent processes like laminating

Benefits of Corona Treatment for PVC Film

Improved Adhesion – Enhances bond strength for coating and lamination.

Increased Wettability – Allows adhesives to spread evenly, reducing defects.

Cost-Effective Solution – More economical than chemical primers or flame treatment.

Fast and Continuous Processing – Can be integrated into production lines without slowing down throughput.

Long-Lasting Effects – Properly treated PVC film retains its enhanced surface energy for weeks

(if stored correctly).

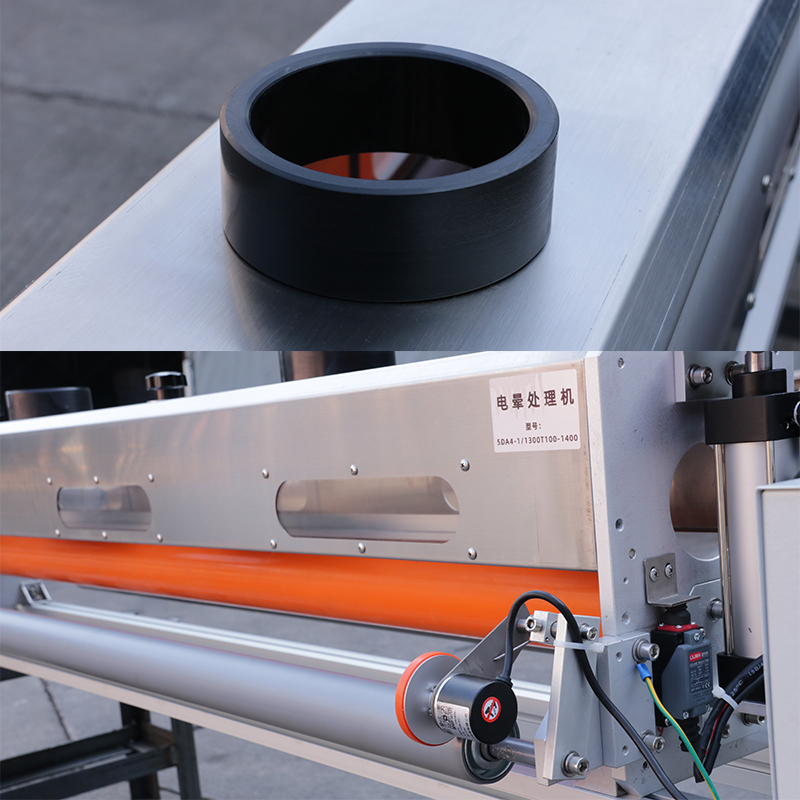

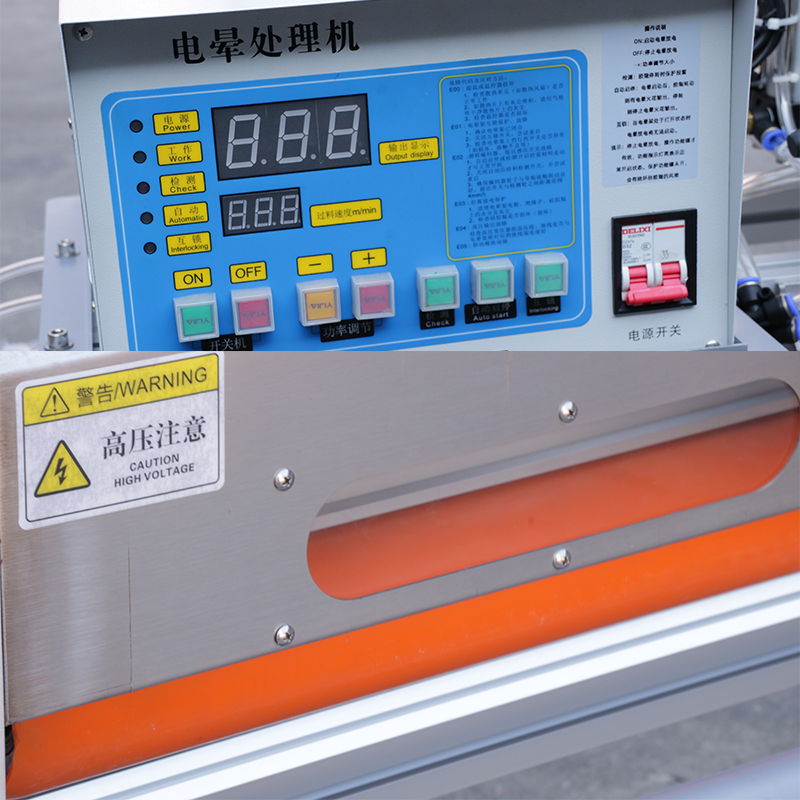

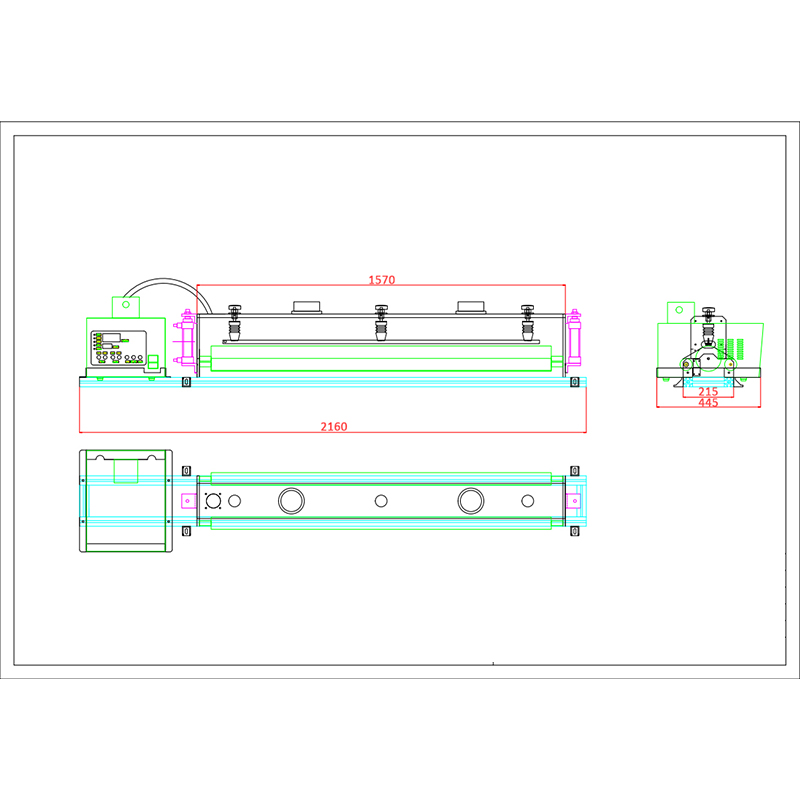

Main unit functions:

main power switch, start, stop, power display, material passing speed display,

power + and - adjustable at will, detection, automatic start and stop.

Detection protection: When the detected material stops moving, the machine will automatically

shut down with an audible alarm.

Automatic start and stop:

When the electric motion sensor is in operation and stops halfway, the

high-voltage output of the electric motion sensor stops. If the material moves again, the high-voltage

output of the electric motion sensor will automatically start without manual operation.

Interlock protection:

When the halo frame is not closed or opened during operation, high voltage is output.

At this time, the operation start button is invalid, ensuring the safety of personnel and equipment

Over-temperature protection:

When the temperature of the main rectifier power supply and the drive

module is too high, the machine will automatically shut down for protection.

Corona treatment machines play a critical role in enhancing the surface properties of PVC film, enabling superior laminate quality, strong adhesive bonding, and high-performance coatings. By selecting the right machine and maintaining proper treatment parameters, manufacturers can significantly improve product performance while reducing material waste.

As the demand for high-quality laminated PVC films grows, advanced corona treatment systems will continue to be an indispensable tool in modern manufacturing.

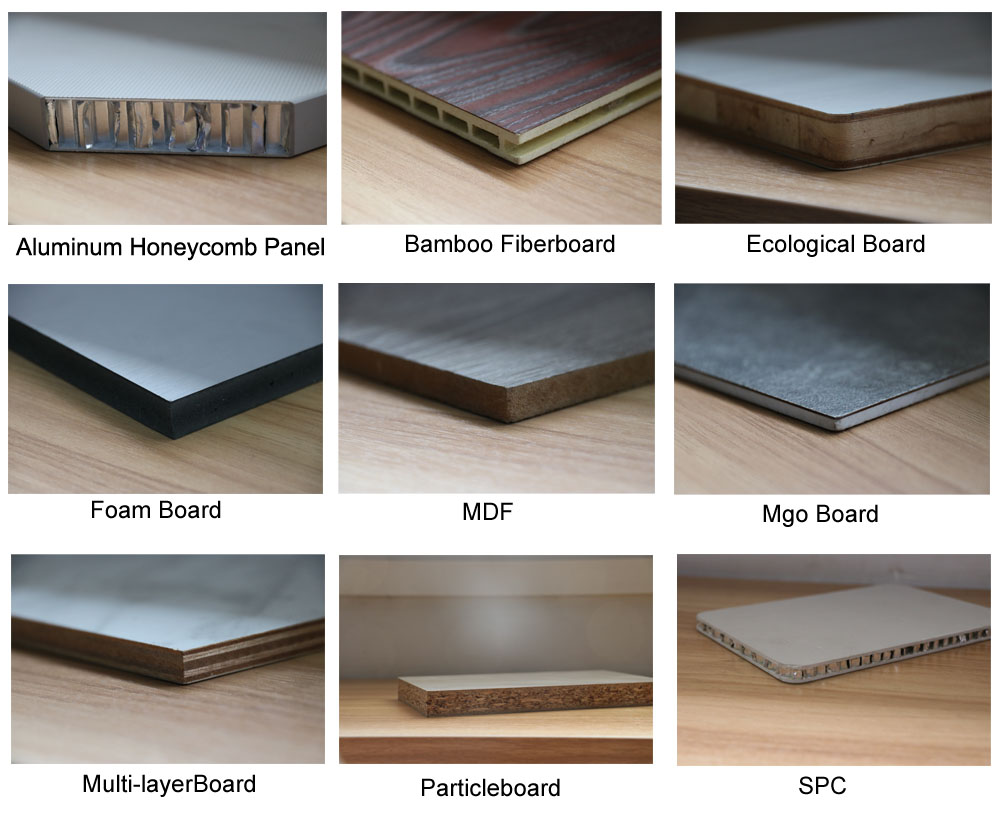

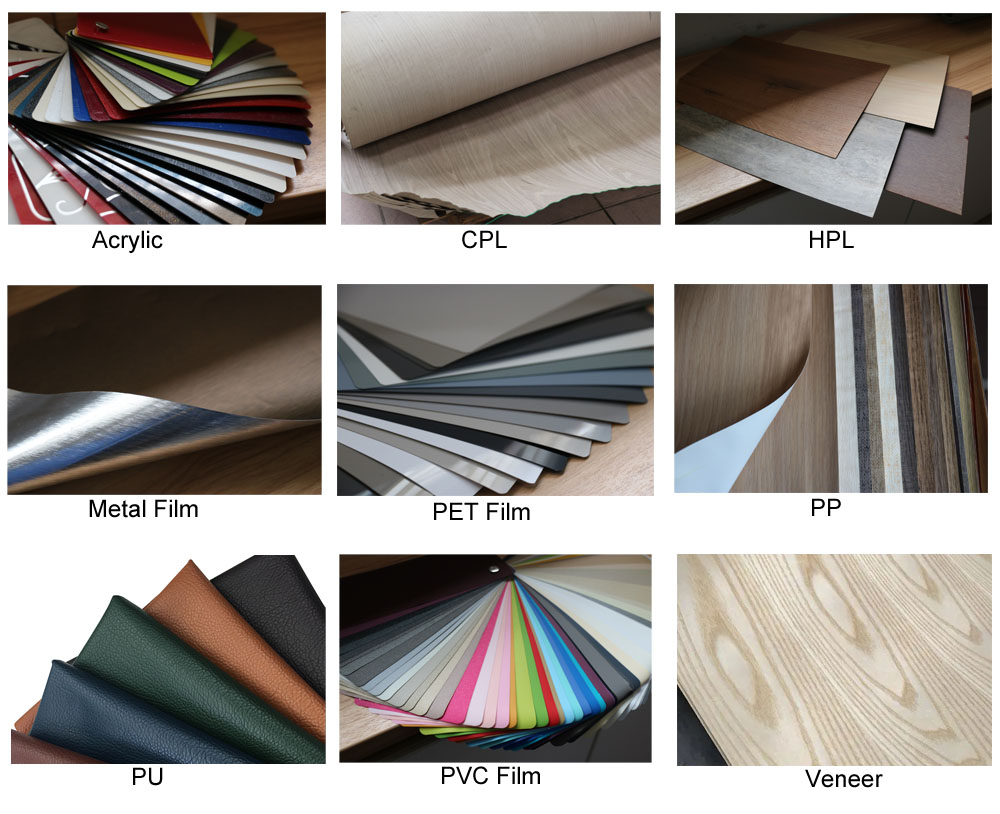

Material Plate

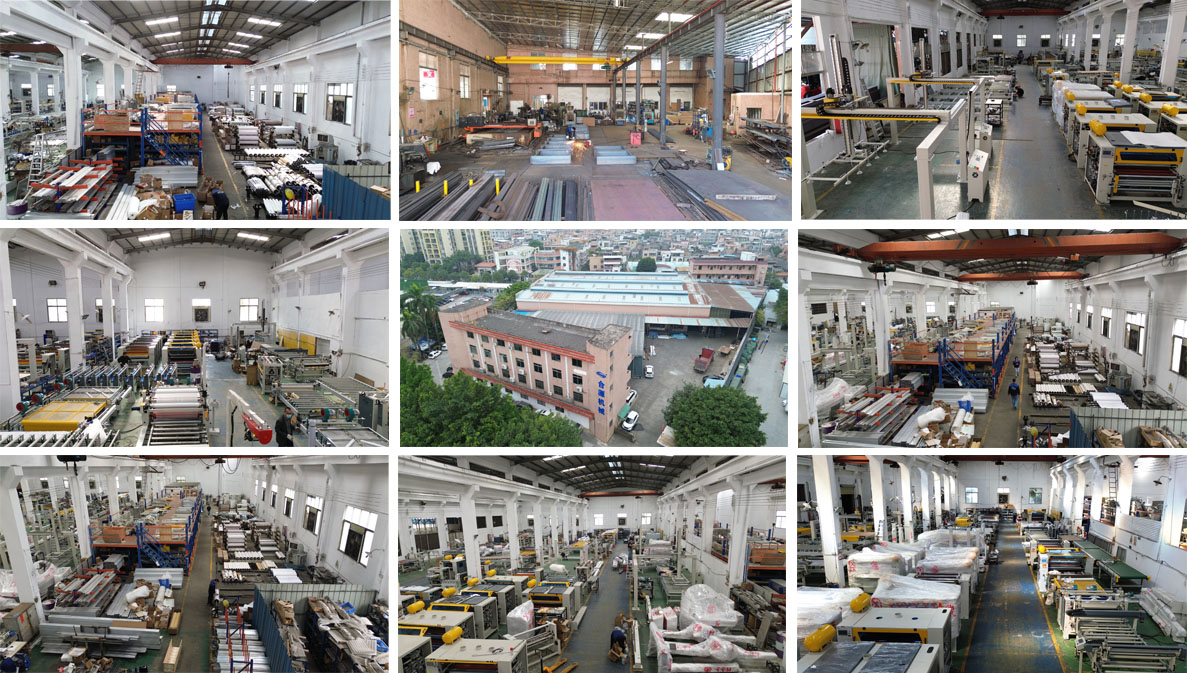

Our Factory

Company Certificate

Our Clients

Our Partners