The Advantages of Using a Single Pair Roller for Lamination

Lamination is a critical process in various industries, from packaging to printing, where materials are

bonded together to enhance durability, appearance, and functionality. One method of achieving

effective lamination involves the use of rollers. Among the various configurations available, the single

pair roller setup stands out for its unique advantages. This article explores why a single pair roller

system is often the preferred choice for lamination processes.

1. Simplicity and Ease of Use

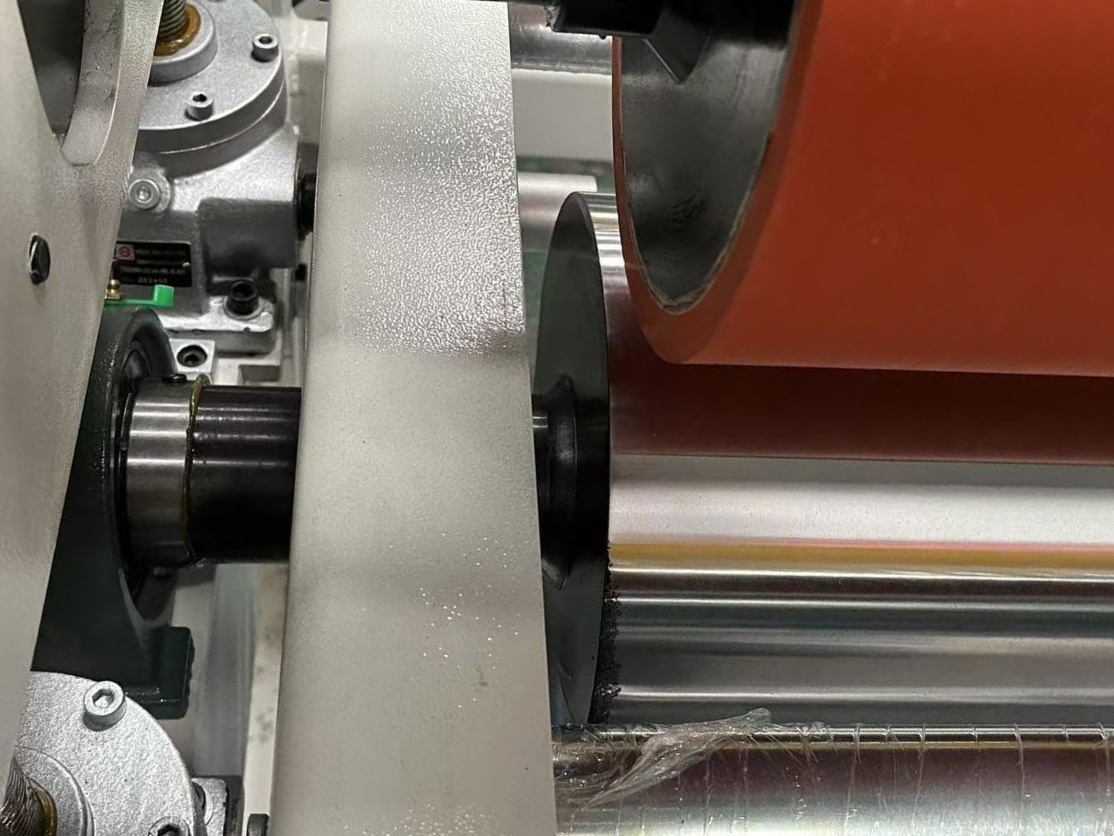

One of the primary benefits of a single pair roller system is its simplicity. This configuration typically

consists of two rollers: one driven and one idler. The straightforward design allows for easier operation,

making it accessible for operators with varying levels of experience. Fewer components mean less

complexity, which can lead to reduced training time and quicker onboarding for new staff.

2. Cost-Effectiveness

In an era where cost efficiency is paramount, single pair rollers present a compelling financial advantage.

With fewer parts than multi-pair systems, they are generally less expensive to manufacture and maintain.

This reduction in initial investment and ongoing maintenance costs can significantly lower the total cost

of ownership, making single pair rollers an attractive option for businesses looking to optimize their budgets.

3. Space Efficiency

Manufacturing environments often have limited space for equipment. The compact design of a single

pair roller system allows it to fit comfortably into smaller production areas without sacrificing performance.

This space efficiency is particularly beneficial for small to medium-sized operations that need to maximize

their equipment footprint.

4. Consistent Pressure Distribution

Uniform pressure is crucial in achieving high-quality lamination. A single pair roller setup can provide consistent

pressure across the entire width of the material being laminated. This uniformity ensures that the adhesive bonds

effectively, resulting in a superior final product.

5. Ease of Adjustment

Another significant advantage of single pair rollers is the ease of making adjustments. The gap between the rollers

can be quickly modified to accommodate different material thicknesses, allowing for rapid changes in production

without extensive downtime. This flexibility is essential in today's fast-paced manufacturing environments, where

adaptability can be a key differentiator.

6. Ideal for roll Materials

Single pair rollers are particularly effective for lamination processes involving roll materials. These applications

require precise control over the lamination process to avoid damaging delicate substrates. A single pair roller

system provides the necessary control and sensitivity, ensuring that materials are laminated effectively without

compromising their integrity.

7. Lower Energy Consumption

Energy efficiency is a growing concern for manufacturers seeking to reduce operational costs and environmental

impact. Single pair roller systems typically consume less energy than more complex multi-roller configurations.

This reduced energy consumption not only lowers operating costs but also contributes to a more sustainable

production process.

Conclusion

In conclusion, the single pair roller system offers numerous advantages for lamination processes. Its simplicity,

cost-effectiveness, space efficiency, consistent pressure distribution, ease of adjustment, suitability for roll materials,

and lower energy consumption make it an ideal choice for many applications. As industries continue to seek efficient

and high-quality production methods, the single pair roller stands out as a reliable and effective solution for achieving

superior lamination results. Whether in packaging, printing, or other sectors, investing in a single pair roller system can

lead to improved operational efficiency and product quality.