Advantages of Using Solvent-Based Adhesives for Acrylic (PMMA) Lamination with PVC Films

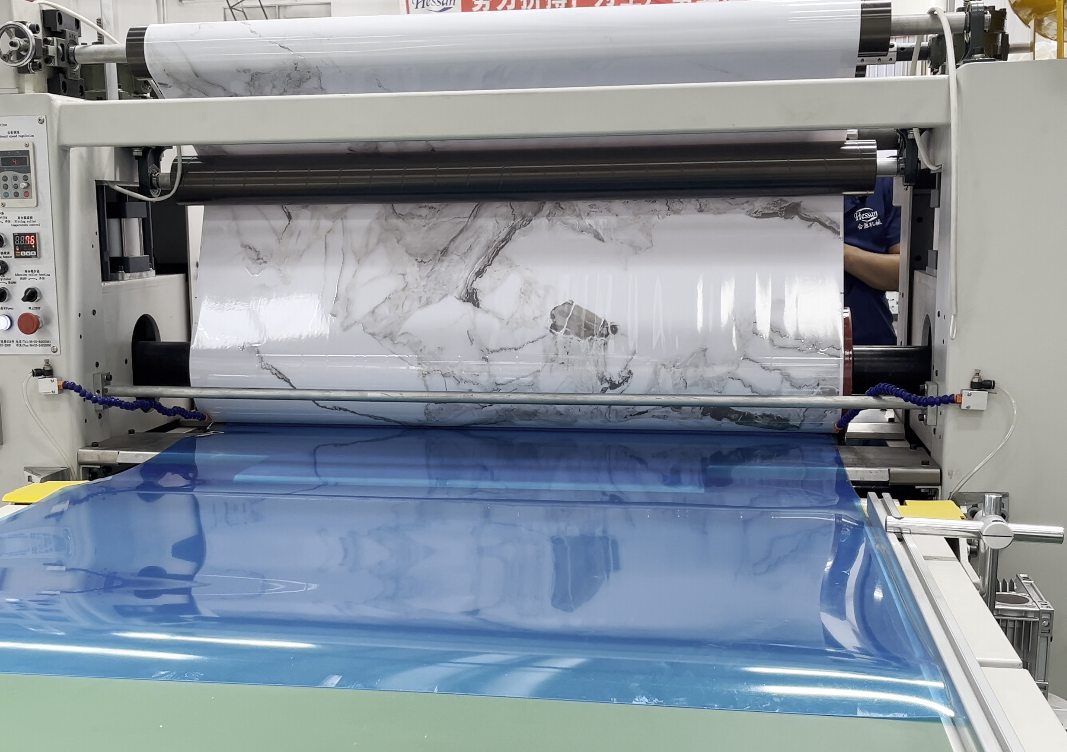

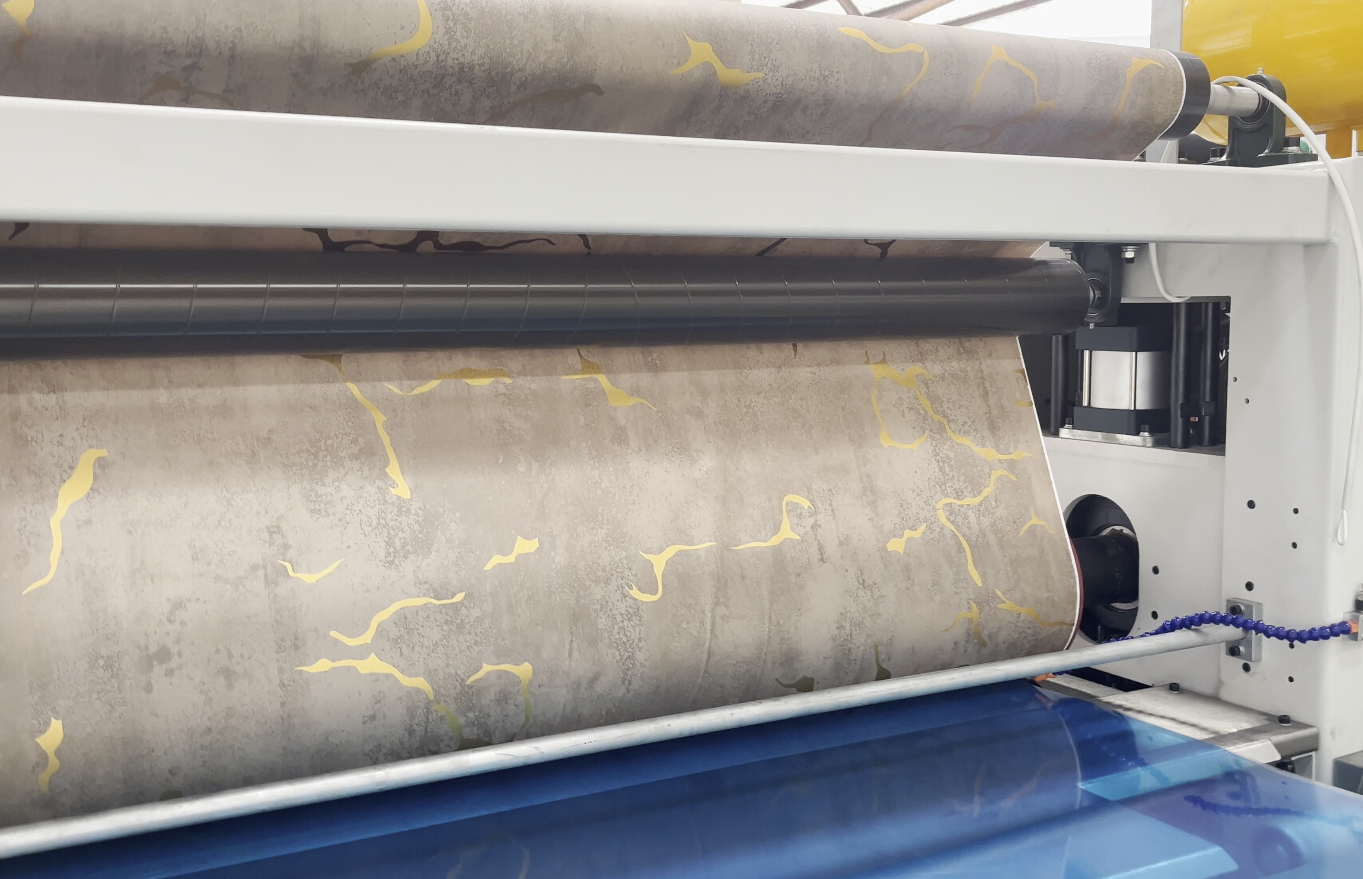

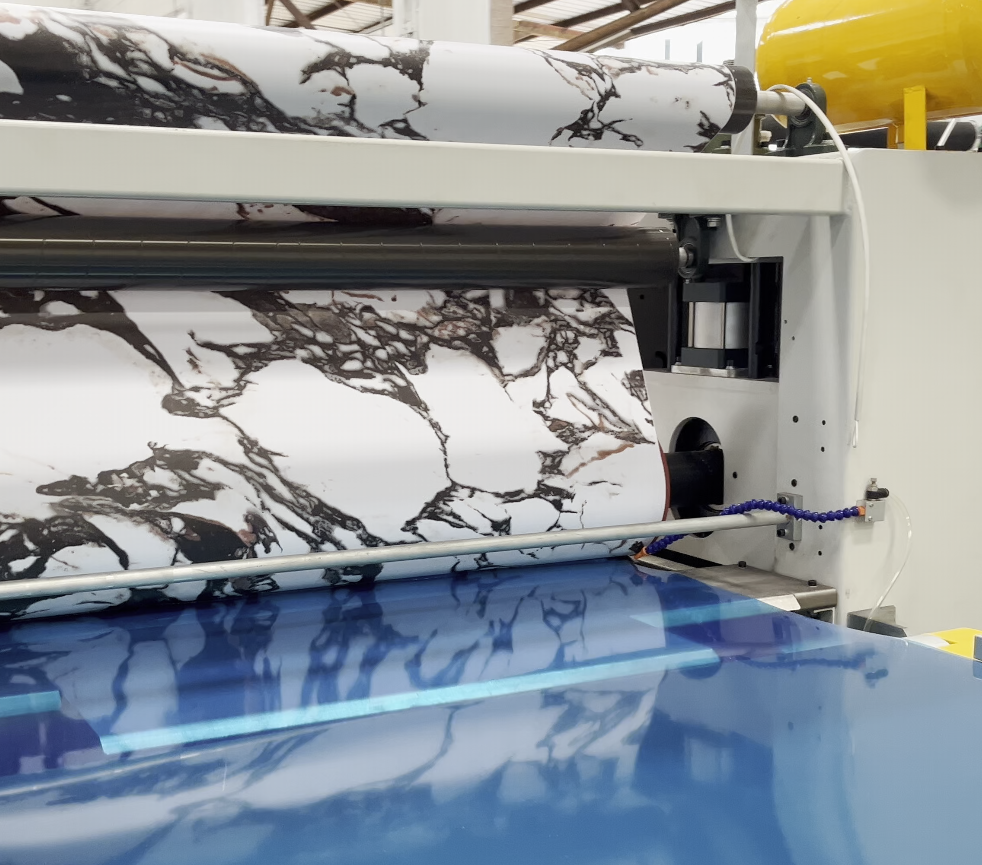

The process of laminating PVC films onto acrylic (PMMA) substrates using solvent-based adhesives offers significant advantages in applications requiring high bond strength, weather resistance, or rapid curing. Below is a detailed analysis of its key benefits and suitable use cases.

Key Advantages of Solvent-Based Adhesives for PVC Film Lamination

1. High Bonding Strength

Solvent-based adhesives (e.g., solvent-borne acrylic or polyurethane adhesives) form a tough adhesive layer after curing, achieving a peel strength of 8-15 N/cm—far exceeding some water-based adhesives. This makes them ideal for long-term applications requiring resistance to warping or delamination (e.g., outdoor signage, automotive interiors).

2. Superior Weather Resistance

Resistant to UV rays, high temperatures, and humidity, with stable performance in temperatures ranging from -30°C to 80°C. Suitable for long-term outdoor use (e.g., architectural facades, traffic signs).

3. Fast Initial Tack

Solvent evaporation ensures quick initial adhesion (5-30 seconds), minimizing film shifting during production and improving assembly line efficiency.

4. Compatibility with Complex Surfaces

The solvents slightly dissolve the acrylic surface, enhancing penetration and filling minor scratches or uneven areas, reducing bubble formation.

5. Chemical Resistance

Resistant to oils, cleaning agents, and other chemicals, making it suitable for frequently cleaned surfaces (e.g., kitchen panels, medical equipment housings).

Typical Applications

Outdoor Signage: High-durability film lamination resistant to rain and UV exposure.

Automotive Interiors: PVC film lamination on acrylic dashboards, withstanding heat and vibration.

Industrial Equipment Panels: Protective layers exposed to oils or chemicals.

Process Considerations

1. Ventilation & Safety

Solvent-based adhesives contain volatile organic compounds (VOCs). Work in well-ventilated areas or facilities with exhaust treatment systems to minimize health risks.

2. Adhesive Thickness Control

Apply adhesive precisely (typically 50-100 g/m²). Excess adhesive may lead to solvent retention, causing bubbles or delayed curing.

3. Curing Time Optimization

Surface drying: 2-5 minutes

Full curing: 24 hours (can be reduced to 1-2 hours with heat curing at 60°C).

Comparison with Water-Based and UV Adhesives

| Property | Solvent-Based Adhesive | Water-Based Adhesive | UV Adhesive |

|---|---|---|---|

| Bond Strength | High (heavy-duty applications) | Medium (lightweight products) | High (but more brittle) |

| Curing Speed | Fast (solvent evaporation) | Slow (requires drying) | Instant (seconds under UV) |

| Cost | Low to medium | Low | High |