Flat lamination process and primer treatment for acrylic machine and PVC

In the modern manufacturing industry, acrylic and PVC (polyvinyl chloride), as two commonly used

plastic materials, are favored for their unique properties and wide range of application scenarios.

Flat laminating acrylic and PVC and applying primer treatment with a primer coating machine in the

process can significantly improve the quality and performance of the product. This paper will discuss

the specific process, advantages and application areas of this process.

1. Acrylic and PVC properties

Acrylic, often referred to as PMMA (polymethyl methacrylate), known for its excellent light transmission,

weather resistance and mechanical strength. Its transparency is comparable to that of glass, and its light

weight makes it easier to process, while PVC is widely used in construction, packaging and automotive

applications for its good corrosion resistance, abrasion resistance and economy.

Despite the advantages of each, when combined, especially in coating and bonding, they may face a lack

of adhesion. This is where the primer treatment becomes particularly important.

2. Steps in the flat lamination process

Step 1: Preparation

Before flat lamination of acrylic to PVC, surface preparation of the acrylic is first required. This includes

cleaning the surface, tear off the protective film.

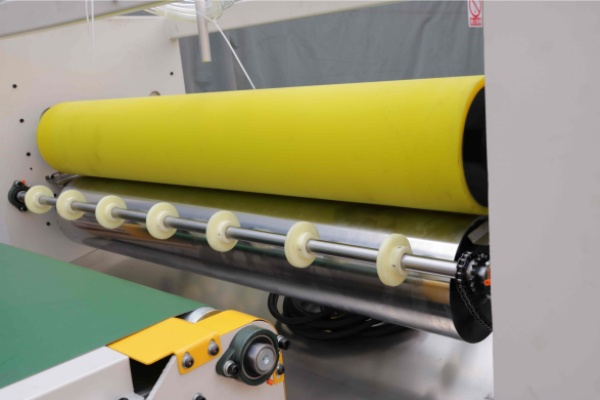

Step 2: Application of acrylic machine

Acrylic machine is a specialized equipment for processing acrylic materials, through the application of

adhesive and laminating process, to get the required acrylic. In this process, acrylic and PVC materials

need to be accurately aligned and laminated to ensure that they can be perfectly combined. The high

precision and automation function of the acrylic machine can effectively improve the production efficiency

and the quality of the finished product.

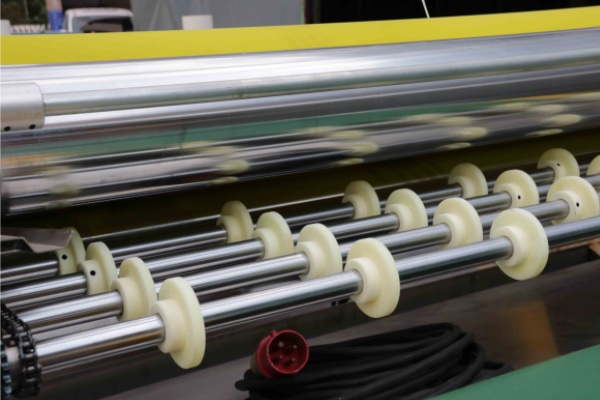

Step 3: primer treatment

After the completion of the flat paste, the use of primer coating machine for PVC primer treatment is to

enhance the adhesion of the key steps. By evenly coating the primer, the primer can effectively fill the

small defects on the PVC surface and enhance the adhesion of the subsequent coating. The choice of

primer material is crucial, and there are usually water-based and solvent-based primers available.

Water-based primers are environmentally friendly and easy to clean, while solvent-based primers usually

have stronger adhesion.

3. Advantages of primers

Improved adhesion: A primer can significantly improve the adhesion of the coating to the PVC, preventing

flaking due to temperature changes or humid conditions.

Smooth surface: After primer coating, the smoothness of PVC surface is improved, which lays a good

foundation

for subsequent coating or printing process.

Environmental protection: Modern primer coating machines are mostly made of environmentally friendly

materials, which reduces the emission of harmful substances and meets the requirements of today's green

manufacturing.

Automation: The bottom coating machine is equipped with automation control system, which can realize

accurate coating, improve production efficiency and reduce labor cost.

4. Application areas

The products that are flat-pasted with acrylic and PVC and treated with undercoating are widely used in

many fields:

Building decoration: in the building facade and interior decoration, the combination of acrylic and PVC

can achieve beautiful and durable effect.

Advertising signs: the combination of transparent acrylic and PVC can produce brightly colored and

weather-resistant billboards.

Automotive interior: Through this process, vehicle interiors can realize rich visual effects and improve

durability at the same time.

Household goods: acrylic and PVC combination of storage boxes, display racks and other products,

due to its good aesthetic and practicality and popular.

5. Conclusion

Flat-pasting acrylic with PVC, combined with the use of primer coating machine, can not only improve

the adhesion and surface quality of the product, but also improve production efficiency and environmental

protection. This process has demonstrated its unique advantages in a number of industries, meeting the

market demand for high-quality products. With the continuous progress and innovation of technology,

this process is expected to be applied in more fields in the future, promoting the development of the

plastics processing industry.