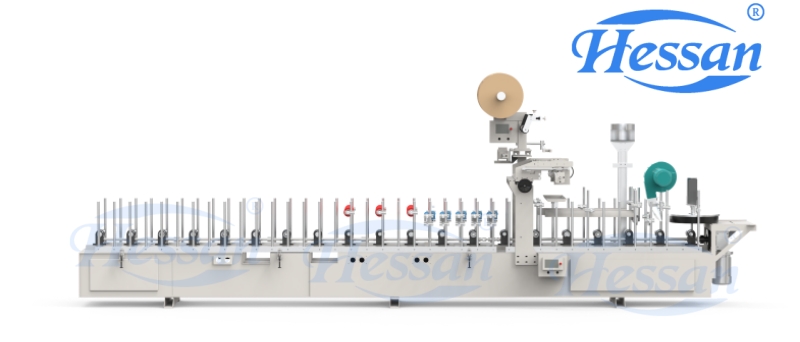

In today’s fast-paced manufacturing landscape, efficiency, precision, and versatility are non-negotiable

for industries ranging from furniture production to architectural design. Enter the High-Speed PUR

Profile Wrapping Machine—a cutting-edge solution engineered to redefine surface finishing for wood,

WPC (wood-plastic composite), and aluminum profiles. Leveraging advanced

PUR (polyurethane reactive) hot melt glue technology, this machine delivers unmatched speed,

durability, and aesthetic quality for coating PVC/PP films, CPL (continuous pressure laminate),

and natural veneers. In this article, we explore its groundbreaking features, operational workflow,

and transformative impact on modern manufacturing.

1. The Core Technology: PUR Hot Melt Glue

At the heart of this machine lies PUR hot melt adhesive, a game-changer in industrial bonding.

Unlike traditional adhesives, PUR glue reacts with moisture in the air to form an exceptionally strong,

flexible, and heat-resistant bond. This thermosetting property ensures:

Superior Adhesion: Bonds seamlessly to diverse substrates, including porous wood, slick aluminum,

and composite materials.

Resistance to Environmental Stress: Withstands temperature fluctuations, humidity, and UV exposure,

making it ideal for indoor and outdoor applications.

Eco-Friendly Efficiency: Generates minimal waste and eliminates solvent emissions, aligning with green

manufacturing standards.

The machine’s PUR melter maintains precise glue viscosity and temperature (typically 120–140°C) to

ensure optimal flow through the slot nozzle, a critical component for uniform glue application.

2. Key Components and Workflow

The PUR profile wrapping machine integrates a meticulously designed system to automate and streamline the coating process. Let’s break down its components and workflow:

A. Pre-Treatment Phase

Dual Dust Cleaners:

The process begins with two-stage particle removal:

Air Blowing System: High-pressure jets dislodge loose dust and debris from the profile surface.

Vacuum Extraction: A suction mechanism removes residual particles, ensuring a contaminant-free

substrate for maximum adhesive bonding.

Primer Application (Optional):

For challenging materials like non-porous aluminum, a primer is applied to enhance surface receptivity

to glue.

Preheating Lamps:

Infrared lamps heat the profile to a controlled temperature (typically 40–60°C). This step:

Removes residual moisture.

Softens the substrate for better glue penetration.

Prepares the surface for immediate film/veneer application.

B. Glue Application

PUR Melter and Slot Nozzle:

The PUR adhesive is fed from the melter to a slot nozzle, which deposits a thin, even layer of glue onto

the substrate. The nozzle’s adjustable width (e.g., 5–50 mm) accommodates profiles of varying sizes.

Glue Thickness Control:

Precision sensors regulate glue application down to ±0.1 mm, preventing overuse and ensuring

consistent coating quality.

C. Film/Veneer Wrapping

Unwinding Shaft:

Rolls of PVC/PP film, CPL, or veneer are mounted on motorized shafts that feed material seamlessly

into the wrapping unit. Automatic tension control prevents wrinkles or tears.

Quick-Change Wrapping Unit:

A patented mechanism allows operators to switch between film types or veneers in under 60 seconds,

minimizing downtime during batch changes.

D. PLC Control System

The machine’s brain is its programmable logic controller (PLC), which automates every parameter:

Speed synchronization between glue application and film feeding.

Temperature monitoring for glue, preheating lamps, and rollers.

Error detection (e.g., film jams, glue shortages) with instant alerts.

User-friendly HMI (human-machine interface) for recipe storage and one-touch adjustments.

3. Unmatched Speed and Precision: 25 Meters Per Minute

The machine’s headline feature is its 25 meters per minute (m/min) maximum speed—a 30–50%

improvement over conventional systems. To contextualize:

A standard 10-meter profile is wrapped in 24 seconds.

For a factory operating 8-hour shifts, this translates to 12,000 meters of output daily.

This leap in productivity is achieved through:

High-Torque Servo Motors: Enable rapid acceleration/deceleration without sacrificing precision.

Optimized Thermal Management: Preheating lamps and glue melters maintain stable temperatures

even at peak speeds.

Real-Time Feedback Loops: Sensors adjust parameters dynamically to prevent defects like uneven

glue spread or film misalignment.

4. Applications Across Industries

The versatility of the PUR profile wrapping machine makes it indispensable for:

A. Furniture Manufacturing

Cabinet and Door Profiles: Coating MDF or particleboard edges with PVC film for scratch-resistant,

waterproof finishes.

Luxury Veneers: Applying walnut, oak, or exotic wood veneers to create high-end aesthetic surfaces.

B. Architectural and Construction

Window and Door Frames: Wrapping aluminum or WPC profiles with weather-resistant films for UV

protection and color retention.

Interior Cladding: Coating decorative panels with CPL for fire-resistant, easy-to-clean surfaces in

commercial spaces.

C. Automotive and Marine

Trim Components: Durable film wrapping for dashboards, door handles, and boat interiors resistant

to saltwater and humidity.

5. Cost and Sustainability Benefits

Investing in this machine delivers rapid ROI through:

Material Savings:

Glue consumption reduced by 15–20% via precision slot nozzle coating.

Film/veneer waste minimized through automated tension control.

Quick-change units reduce setup time by 70%.

Energy Efficiency:

Infrared preheating consumes 30% less power than traditional convection heating.

PUR glue’s low application temperature cuts energy costs versus hot melts.

6. The Future of Profile Wrapping

As industries demand faster, greener, and more customizable solutions, Hessan’s PUR wrapping

machine is poised to lead the charge. Upcoming innovations include:

AI-Powered Defect Detection: Camera systems integrated with machine learning to identify and correct

flaws in real time.

IoT Connectivity: Remote monitoring of machine performance and predictive maintenance alerts via

cloud platforms.

Hybrid Adhesive Systems: Combining PUR with UV-curable adhesives for ultra-fast curing in

high-humidity environments.

Conclusion

The High-Speed PUR Profile Wrapping Machine is not just a tool—it’s a transformational force for

manufacturers aiming to dominate competitive markets. By marrying blistering speed with surgical

precision, it addresses the pain points of quality control, production costs, and sustainability head-on.

Whether you’re crafting bespoke furniture or engineering storm-resistant building components, this machine ensures every profile leaving your facility is a testament to perfection.

Stay tuned to the Hessan Knowledge Channel for deep dives into operational tips, case studies,

and live demonstrations. The future of industrial coating is here—don’t let your competitors reach it first.