In today's fast-paced panel processing industry, integrating automation with precision-driven

PUR laminating machines is no longer optional – it's essential. At Hessan, we introduce the

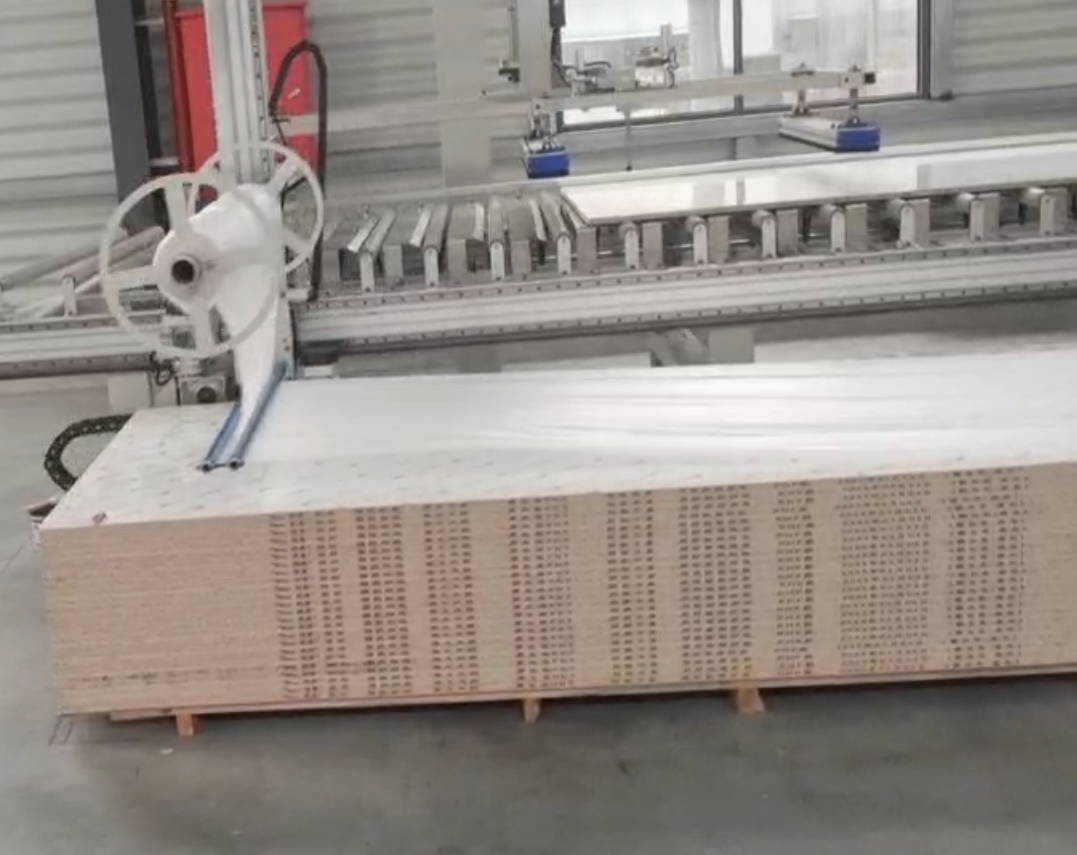

next-generation Auto Crane Frame Loading Machine, engineered to seamlessly pair with your

PUR hot melt laminating equipment, eliminating manual handling while boosting productivity by 300%.

Why Automate Your PUR Laminating Production Line?

PUR (Polyurethane Reactive) adhesives demand rapid, precise material handling due to their

fast-curing properties. Traditional manual loading risks adhesive pre-curing and inconsistent bonding.

Our solution ensures:

✅ 4 panels/minute synchronized with laminator speed

✅ 13 intelligent suction cups (9×120mm + 4×60mm with jiggle separation)

✅ 100% servo-driven positioning (±0.5mm accuracy)

Technical Highlights for PUR Laminate Optimization

Smart Panel Handling System

Processes 4×8ft to 4×10ft panels up to 100kg/pc

60mm jiggle cups prevent double-picking for thin veneers/MDF

120mm heavy-duty cups secure large-format HPL/acrylic sheets

Seamless Integration with PUR Laminators

4.3m(L)×4m(W)×5.3m(H) compact footprint fits inline configurations

Real-time communication with laminating machine PLCs

Dust-resistant design for adhesive coat environments

ROI-Driven Automation

Replace 3-4 workers per shift

Reduce material waste from misalignment by 15%

24/7 operation compatible with edgebanders & cold/hot press lines

Case Study: Automotive Interior Panel Manufacturer

A Zhejiang-based client using PUR laminating machines achieved:

🔹 22% faster cycle times (8hr → 6.5hr/day)

🔹 0% adhesive scrap from delayed loading

🔹 Full ROI in 14 months

Upgrade Your Laminating Workflow Today!

Whether you're bonding decorative films, wood veneers, or composite panels, Hessan's loading

automation ensures your PUR adhesive laminating machine operates at peak efficiency.