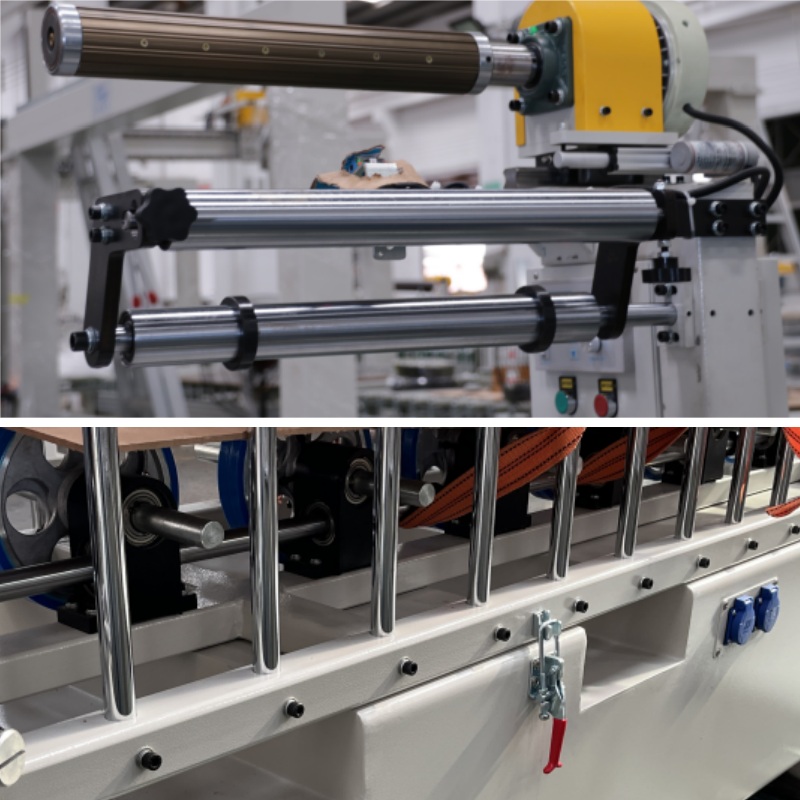

HY-FE-350 Hot Melt Adhesive Profile Wrapping Machine is a highly efficient automatic machine designed for wrapping all kinds of profile surfaces with decorative materials (e.g. PVC film, woodgrain paper, leather, etc.). Through the precise hot melt adhesive coating technology, it can achieve fast and even coating effect, which is widely used in the surface treatment of door and window frames, furniture edge strips, decorative lines, car interiors and other industries. The equipment adopts advanced control system, easy to operate, suitable for a variety of complex profile processing needs.

Technical Parameters:

Model: HY-FE-350| Processing speed: | 0-15m/min(adjustable) |

| Heating power: | 6kW (energy efficient, fast heating) |

| Tank capacity: | 5 gallons (support continuous operation) |

Applicable profile width: | 10-300mm |

Applicable profile thickness: | 5-80mm |

Voltage: | 380V/50Hz (customised) |

Machine size: | 6000×800mm×1700mm(L×W×H) |

| Machine weight: | about 2000kg |

| Applicable film material: | Decorating papper, PVC foils, PU paper, Veneer, PP, CPL etc. |

Application Fields

Building materials industry: door and window frames, skirting, ceiling decorative strips.

Furniture manufacturing: cabinet edging, table and chair coverings, decorative lines

Automotive interiors: dashboards, door trims

Advertising: Acrylic signage, exhibition props

Core Advantages

Strong stability: all-steel body structure, anti-vibration design, suitable for long time continuous production.

Convenient operation: modular design, changeover time <10 minutes, greatly improving production efficiency.

Low maintenance cost: Key components are made of imported wear-resistant materials (e.g. German cylinders,

Japanese bearings), which extends the service life by 50%.

After-sales service

Free technical support: provide remote guidance and on-site installation and commissioning services.

Warranty Policy: 1 year warranty for the whole machine.

Training: Operation and maintenance training (video tutorials + on-site teaching).

After-sales service

·Free technical support: provide remote guidance and on-site installation and commissioning services.Warranty Policy: 1 year

·Warranty Policy: 1 year warranty for the whole machine.

·Training: Operation and maintenance training (video tutorials + on-site teaching).

Environmental protection and safety: Comply with CE standard, equipped with smoke filters to ensure a clean

working environment.