What is the biggest wear and tear item in a PUR flat laminating machine?

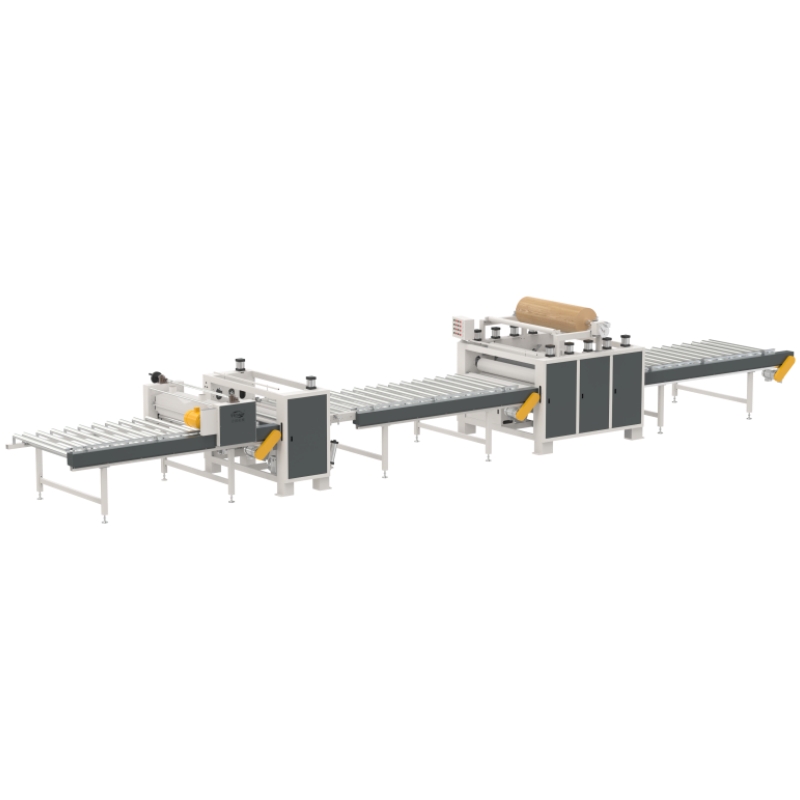

PUR flat lamination line :

In the complex mechanical world of a PUR flat laminating machine, there is one component that stands out as the item most susceptible to wear and tear - the silicone rollers on the coating machine. These silicone rollers play a crucial role in the laminating process, yet their constant interaction with the board and the glue over extended periods of time subjects them to significant deterioration.

Over time, the surface of the silicone rollers can start to show signs of wear. It might develop small scratches, grooves, or a loss of its original smoothness. This change in the roller's surface condition can have a direct impact on the quality of the lamination process. For instance, if the roller's surface becomes uneven due to wear, it can lead to an inconsistent application of glue onto the board. This, in turn, may result in areas where the glue layer is too thin or too thick, affecting the adhesion between the layers being laminated and potentially causing issues like delamination or a less than perfect finish on the final product.

Moreover, as the wear progresses, the ability of the rollers to evenly distribute the glue diminishes. The smooth and precise operation that is essential for achieving a high-quality laminated surface starts to falter. This can be particularly problematic when working with materials that require a very fine and even glue coating, such as high-gloss or delicate substrates where any imperfection in the glue layer can be highly visible and detract from the overall aesthetic and functional quality of the laminated item.

However, it's not all doom and gloom when it comes to the lifespan of these silicone rollers. With proper maintenance and careful cleaning practices, their service life can be significantly extended. Regular cleaning is of utmost importance. After each use or at scheduled intervals, the rollers should be thoroughly cleaned to remove any residual glue or debris that might accumulate on their surface. Special cleaning agents that are compatible with the silicone material and the PUR glue can be used to ensure effective removal without causing any damage to the rollers.

But even with the best maintenance efforts, there comes a time when replacement becomes inevitable. And this is where the design features of certain machines, like those offered by HESSAN Machinery, come into play. HESSAN Machinery has equipped its machines with a quick change roller slide, which is a game-changer when it comes to replacing the heavy PUR glue rollers. These rollers can weigh up to 200KG, and without a proper mechanism,

replacing them would be a cumbersome and time-consuming task.

The quick change roller slide simplifies the disassembly and assembly process to a great extent. Operators no longer have to struggle with heavy lifting and complex maneuvers to remove the old, worn-out rollers and install the new ones. With this innovative feature, the process becomes straightforward and efficient. It not only saves valuable time but also reduces the physical effort required from the workers, enabling them to focus more on the actual

production process.