INTORDUCTION

In the modern manufacturing industry, PUR (polyurethane hot melt adhesive) flat lamination line

is highly valued for its efficient bonding performance and environmental protection and a wide range

of applications. However, in the production process, the generation of static electricity and the dust

problems it brings often affect product quality and production efficiency. In order to solve this problem,

many companies began to use electrostatic spray dust removal technology of belt brush. This paper will

introduce the working principle, application advantages and practical precautions of this technology.

Working principle

During the operation of the plate in the PUR flat laminating machine, the friction between the conveying

row and the original dust on the surface of the plate will produce static electricity, which will not only

adsorb the dust, but also may have a negative impact on the adhesion and bonding of the product.

In order to solve this problem, the belt brush electrostatic spray dust removal technology came intobeing.

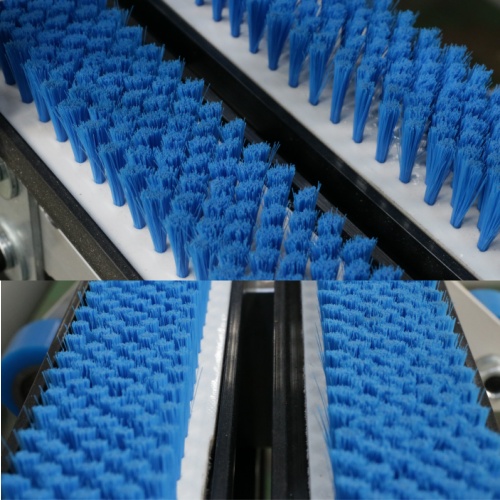

The core of this technology is the combination of belt brush and automatic electrostatic water spraying

two functions. The brush removes dust from the surface of the belt through physical contact, and the

spray system sprays a small amount of electrostatic water mist on the brush surface to further clean the

surface and reduce dust generation. In the specific operation, the spray of water is sprayed on the brush,

and the brush will take away the dust attached to the surface, so as to achieve efficient dust removal

effect.

Application advantage

Effectively improve product quality: By removing static electricity and surface dust, the bonding effect

of the PUR laminating machine is significantly improved, ensuring the quality and appearance of the

final product.

Increased production efficiency: Removal of static electricity and dust reduces line downtime and cleaning

frequency, thereby increasing overall production efficiency.

Environmental protection and safety: Compared with the traditional dust removal method, the spray

dust removal technology is more environmentally friendly, reducing the use of chemical cleaners, and

the spraying of electrostatic water also helps to control static electricity and ensure the safety of the

production environment.

Maintenance equipment: The combination of brush and spray system can effectively reduce the

accumulation of dust on the surface of the equipment, extend the service life of the equipment, and

reduce the frequency of maintenance and replacement of parts.

Precautions for actual operation

In practical applications, the belt brush electrostatic spray dust removal technology of PUR flat

laminating machine should pay attention to the following aspects:

Equipment selection: Select the appropriate brush and spray system according to the production requirements.

The tension of the belt should not be adjusted too tightly to avoid damage to the belt.

Installation position: The installation position of the brush and spray system should be rationally arranged

to ensure that the spray can cover the entire brush working area to achieve the best dust removal effect.

Regular maintenance: Check the working status of the brush and spray system regularly to ensure its

normal operation. The wear degree of the brush should be replaced in time to maintain a good dust

removal effect.

Water quality management: The water used in the spray system should be kept clean to avoid secondary

pollution caused by water quality problems. Clean the spray system regularly to ensure uniform spray.

Operation training: Necessary training for operators, so that they understand the principle of electrostatic

dust removal technology and operation points, to ensure the effective use of equipment.

conclusion

The belt brush electrostatic spray dust removal technology used in PUR flat laminating provides an

efficient and environmentally friendly solution for modern manufacturing industry. By effectively removing

static electricity and dust, it not only improves product quality and production efficiency, but also

reduces safety risks. With the continuous progress of technology, the technology will continue to

develop in the future, providing stronger support for the sustainable development of the manufacturingindustry. Enterprises that adopt this dust removal technology will occupy a favorable position in the

fierce market competition and promote the progress and innovation of the entire industry.