In the PUR (polyurethane) flat lamination process, the corona treatment of the sheet has the following main benefits:

Enhanced surface energy

The surface energy of untreated sheets is low, like some plastic sheets WPC SPC, etc. It is difficult for glues and other coating materials to adhere well to their surfaces. Corona treatment can significantly improve the surface energy of the sheet. For example, an untreated PP sheet may have a surface energy of only 30 - 32 dyne/cm, whereas after corona treatment the surface energy can be increased to about 38 - 42 dyne/cm. This allows the PUR adhesive to spread and wet better on the surface of the sheet, resulting in a strong bond.

From a microscopic point of view, the corona treatment introduces polar groups on the surface of the sheet. These polar groups can interact with the polar components of the PUR adhesive. For example, corona creates polar groups such as hydroxyl (-OH) and carbonyl (C = O) groups on the surface of the sheet, which can form hydrogen or other chemical bonds with groups such as the isocyanate group (-NCO) in the PUR adhesive, enhancing the chemical bonding between the adhesive and the sheet.

Improved wettability

The wettability of the corona-treated sheet to the PUR adhesive is greatly improved. Wettability is the ability of a liquid (glue) to spread on a solid (sheet) surface. Good wettability ensures that the glue covers the surface of the sheet uniformly and avoids localized glue loss or aggregation.

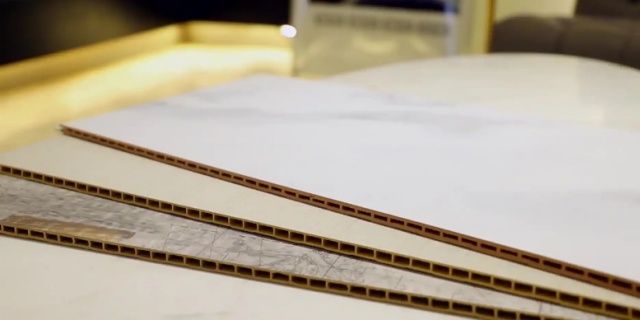

In the case of wood composite panels, for example, after corona treatment, when PUR glue is applied, the glue is able to spread quickly on the surface of the panel, just like water on a cleaned and treated glass surface, and is able to be evenly distributed, which helps to improve the flatness and bonding quality of the laminated panels. If the sheet is not corona treated, the glue may form filaments and cannot spread well, resulting in quality problems such as delamination of the laminated sheet easily.

Improvement of laminating strength

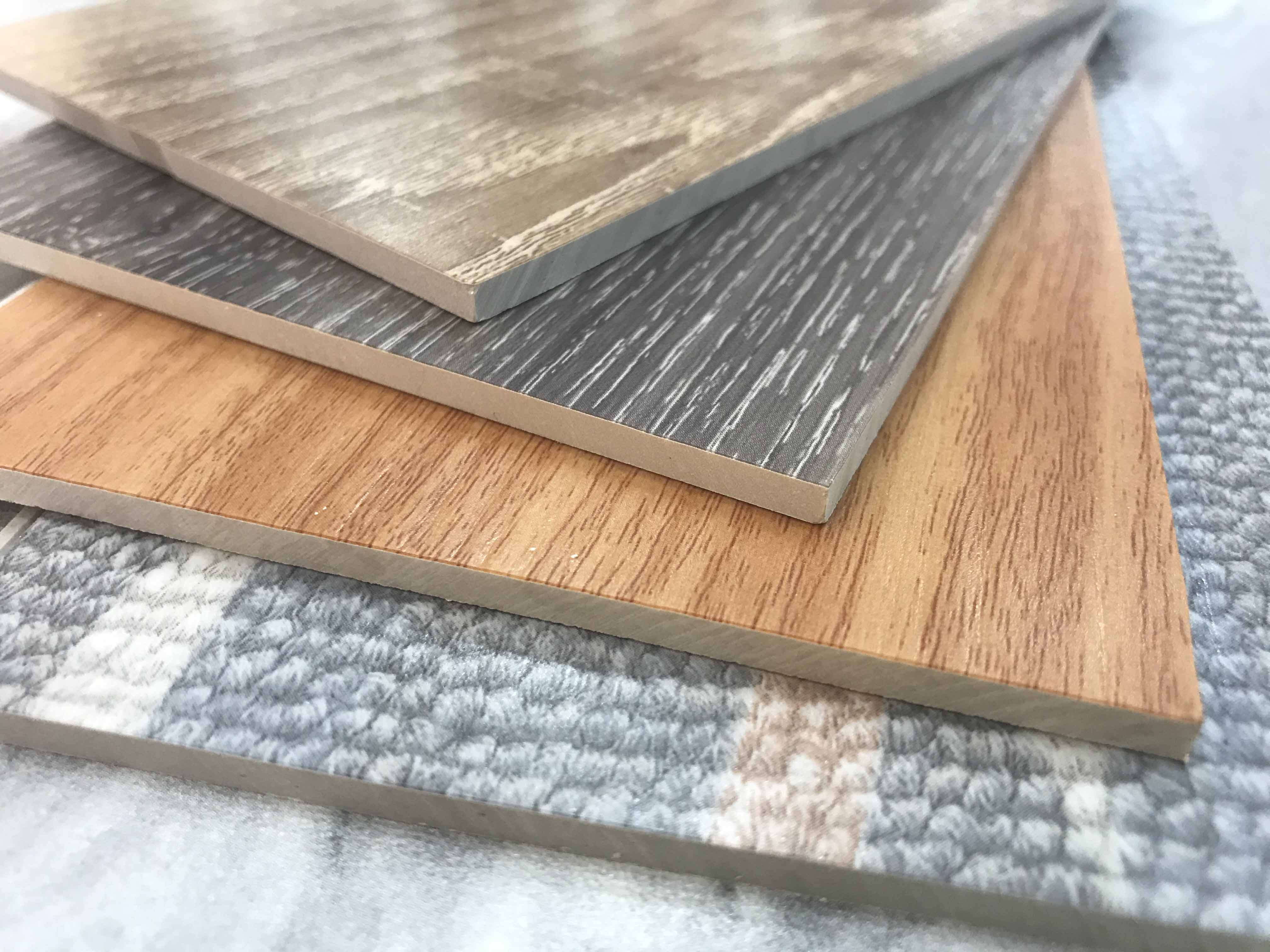

As the corona treatment enhances the physical adsorption and chemical bonding between the adhesive and the sheet, the laminating strength of the sheet after PUR lamination is significantly improved. Whether it is for the same kind of material laminating between the sheets, or different materials (such as metal and plastic, wood and plastic, etc.) between the laminating, can play a very good enhancement effect.

For example, in the PVC and stone plastic plate through the PUR flat paste process, after corona treatment of stone plastic plate and PVC between the peel strength can be than untreated increased 30% - 50%. Thus, in the subsequent processing and use of the process, such as cutting, sanding, installation and other operations, the PVC on the surface of the plate is not easy to fall off, improving the quality and service life of the product.

Enhance the stability of product quality

Corona treatment is a relatively stable and controllable surface treatment method. It can make the surface state of the plate more uniform, thus ensuring the stability of the PUR flat lamination process. In the mass production process, to ensure that each piece of plate after treatment have similar surface properties, so that the glue in each piece of plate bonding effect is more uniform.

For example, in the furniture manufacturing enterprises, the use of corona-treated plates for PUR flat paste, can effectively reduce the product quality fluctuations caused by differences in surface properties of the plate. The appearance of the product is more flat and beautiful, and in the long-term use of the process, will not be because of the local bonding is not firm and appear deformation, blistering and other quality problems.