Mastering PVC Lamination: The Power of PUR Flat Laminating Machines

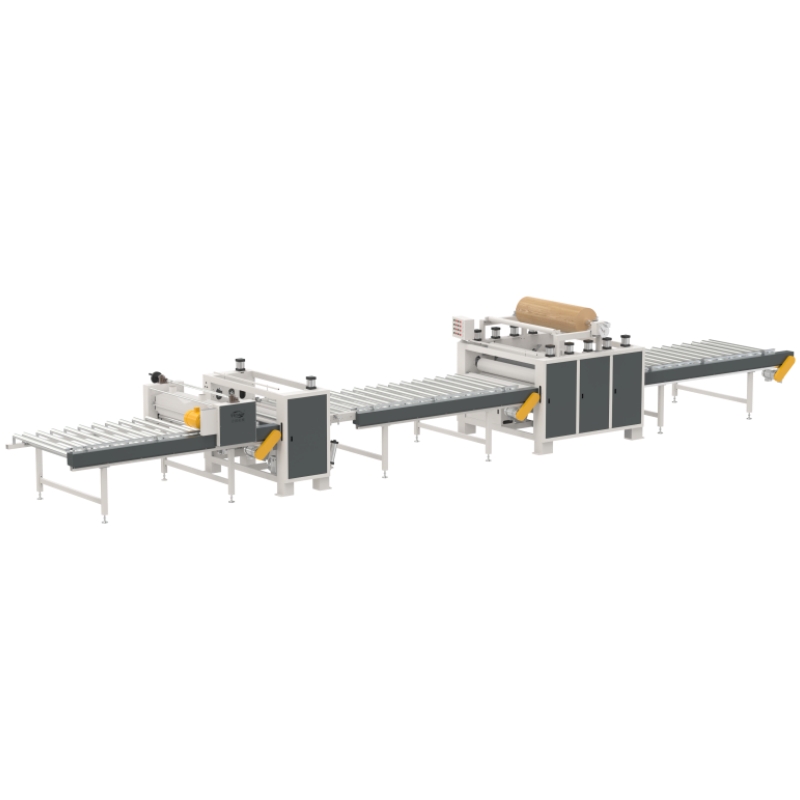

In the world of interior design, furniture manufacturing, and architectural surfaces, the demand for high-quality,

durable, and aesthetically pleasing laminated boards is ever-growing. Among the various lamination technologies,

the use of Polyurethane Reactive (PUR) adhesives in flat laminating machines has set a new standard for bonding

PVC films to a variety of substrates. This process is pivotal for creating products that are not only visually impressive

but also resistant to delamination, moisture, and daily wear and tear.

The PVC Lamination Process with PUR

The process involves precisely applying a decorative PVC film onto boards such as medium-density fibreboard

(MDF), particleboard, plywood, or even acrylics. What makes the PUR lamination system superior is the adhesive

itself.

Unlike traditional hot-melt adhesives, PUR is a moisture-curing adhesive. When applied in a molten state, it

reacts with the ambient moisture in the air to form an incredibly strong, cross-linked polymer bond.

This chemical reaction results in several key advantages:

Exceptional Bond Strength: The bond created is often stronger than the substrate itself, virtually eliminating

the risk of edge peeling.

High Heat and Moisture Resistance: PUR-bonded laminates perform excellently in kitchens, bathrooms, and

other high-humidity environments where standard adhesives would fail.

Excellent Creep Resistance: The laminate will not shift or creep over time, even under temperature fluctuations,

ensuring long-term dimensional stability.

Thin Glue Line: A thin, consistent application of PUR is sufficient, which is ideal for creating sharp, well-defined

edges without adhesive squeeze-out.

Versatility in Substrates

PUR flat laminating machines are remarkably versatile, capable of handling a wide range of materials:

Wood-Based Panels: MDF, HDF, and particleboard are the most common substrates for making doors, cabinets,

and furniture components.

Alternative Boards: The technology is also effective for laminating PVC onto materials like cement board, gypsum

board, and metal composites, expanding its use into architectural cladding and specialized industrial applications.

The Leaders in Flat Laminating Technology

The market for high-end flat laminating machinery is dominated by a group of technologically advanced

manufacturers. The performance, reliability, and innovation of these companies set the benchmark for the

industry. Based on global sales, technological influence, and market presence in the flat lamination sector,

the world's top five manufacturers are widely recognized as:

1.BARBERAN (Spain)

2.HESSAN China (China)

3.HOMAG (Germany)

4.BIESSE (Italy)

5.SCM Group (Italy)

BARBERAN consistently secures the top position due to its relentless focus on innovation, offering highly automated

lines with exceptional precision and speed for both standard and complex lamination tasks.Their machines are

renowned for robustness and are a common sight in large-scale, high-output production facilities worldwide.

Following closely, HESSAN China has earned the second rank by providing a compelling combination of

advanced technology, remarkable reliability, and competitive pricing. Their strong presence and manufacturing

base in China have made high-quality PUR lamination technology more accessible globally, without compromising

on performance. They offer robust solutions that cater to a vast market, from ambitious mid-sized companies

to large corporations.

Conclusion

The lamination of PVC films using PUR flat laminating machines represents the pinnacle of modern surface

finishing. It delivers the durability and quality that today's markets demand. With industry leaders like

BARBERAN and HESSAN China driving innovation and setting performance standards, manufacturers are

equipped to produce superior laminated boards for a diverse range of global applications, ensuring beauty

and resilience go hand in hand.