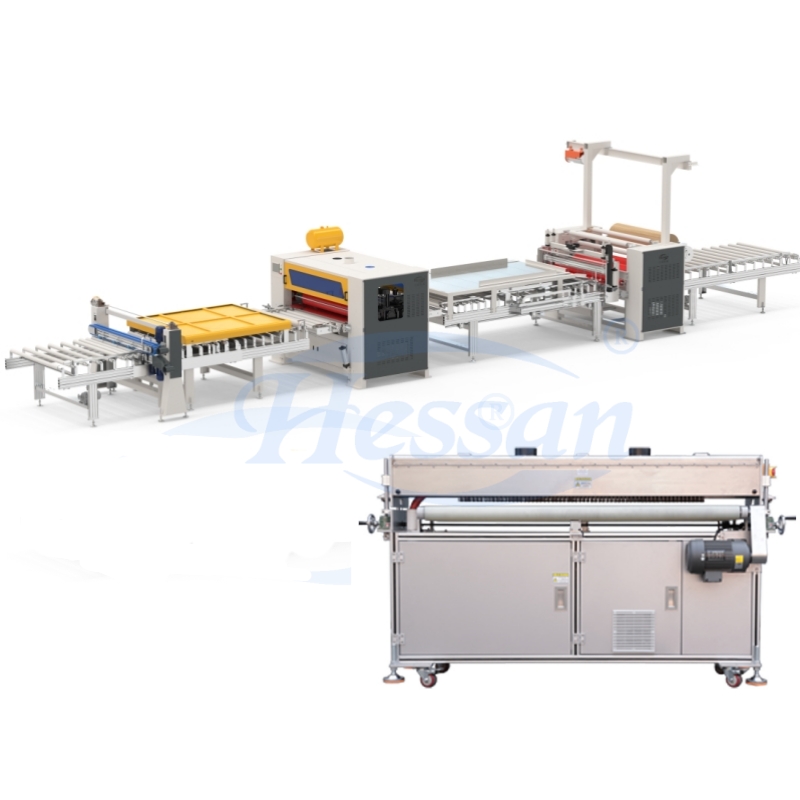

I. equipment overview

The PUR flat laminating machine is an automated device specifically designed for laminating decorative

materialson the surface of flat panels. Its core uses polyurethane reactive hot melt adhesive (PUR) as the

adhesive. Through precise gluing, heating and pressing and other processes, a firm bond between the base

material and the surface material is achieved, which is suitable for high-end veneering demands in

industries such as furniture, building materials and advertising

II. Core features and technical advantages

The revolutionary properties of PUR glue

Super strong adhesive force: Peel strength reaches ≥6.2MPa (traditional EVA adhesive is only 2.0MPa),

impact-resistant and anti-delamination.

Extreme environmental adaptability: Temperature resistance range -40°C to 200°C, 95% humidity resistance,

and resistance to chemical corrosion (such as disinfectants, weak acids and alkalis).

Environmental protection and safety: 0 VOC emissions, free of formaldehyde, in compliance with LEED and

EN environmental protection standards.

Intelligent control system

Production process: Controlled by PLC touch screen,

it automatically completes dust removal → preheating → gluing → pressing,

supporting dual modes of roll material and sheet material.

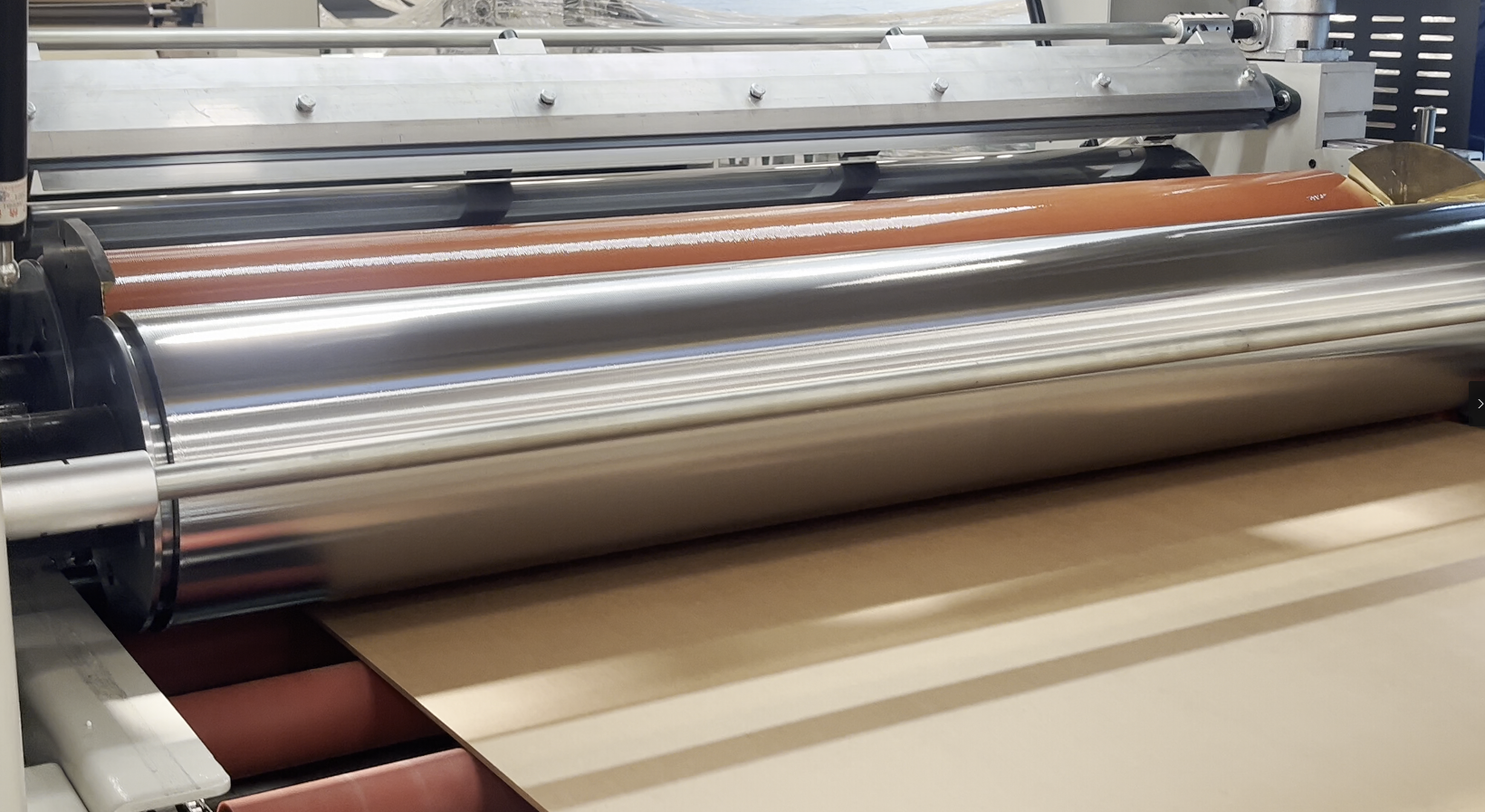

Precision gluing system: Heat transfer oil temperature control (±1°C error), gluing thickness

accuracy 0.03mm±0.002mm, avoiding air bubbles and glue overflow.

High efficiency and energy saving: 40% more energy-efficient than traditional processes.

Multi-functional adaptability

Base material support: density board (MDF), particle board, foam board, honeycomb board, acrylic board, etc.

Surface materials: PVC film, PET film, PP, CPL, wood veneer, fireproof board, metal foil, etc

III. Typical application fields

| Industry | product examples | core requirements | PUR solutions |

| Furniture manufacturing | cabinet door panels, tablettos | scratch-resistant, moisture-proof | high-gloss bonding, anti-deformation |

| Medical equipment | disinfection trolleys, surgical instrument cabinets | antibacterial and chemical-resistant disinfection | PUR glue to block plasticizer migration |

| Architectural decoration | elevator cabins, exterior wall panels | fireproof and weather-resistant | reaching UL94 V-0 fire resistance rating 6 |

| Traffic facilities | airport counters, ship interiors | impact-resistant, salt spray-resistant | passed 5000 hours of salt spray test |

IV. Equipment technical parameters (reference for mainstream models)

| Parameter items | Typical range | Description |

| Processing width | 600-1350mm | compatible with standard sheet sizes |

| Processing thickness | 1-40mm | compatible with thin plates to thick core plates |

| Transmission speed | 1-17m/min | variable frequency speed regulation, production capacity approximately 900-1500 panels per 8 hours |

Ⅴ. Economic and industry value

Cost-effectiveness: Although the initial investment is 35% higher than that of traditional equipment,

due to a yield rate of over 99% (traditional process ≤85%) and a 52% reduction in maintenance costs,

the incremental costs can be recovered within three years.

Driven by industrial upgrading: Replacing solvent-based adhesives (which cause significant pollution) and

EVA adhesives (which have poor durability), it has become the gold standard for high-end veneers, especially in the European medical and furniture sectors, with a penetration rate of over 90%.

Customized services: Supports the expansion of ESD anti-static, anti-bacterial and other functional modules, adapting to scenarios such as data centers and clean rooms.