I. Core applicability (strong signals for choosing full automation)

1. High-volume, large-scale production

This is the central determining factor.

High capacity requirements: If you need to process hundreds or even thousands of boards (e.g., cabinet doors, table tops, decorative boards) every day, every week, the unrivalled speed and continuity of a fully automated line can dramatically increase capacity and ensure that orders are delivered on time.

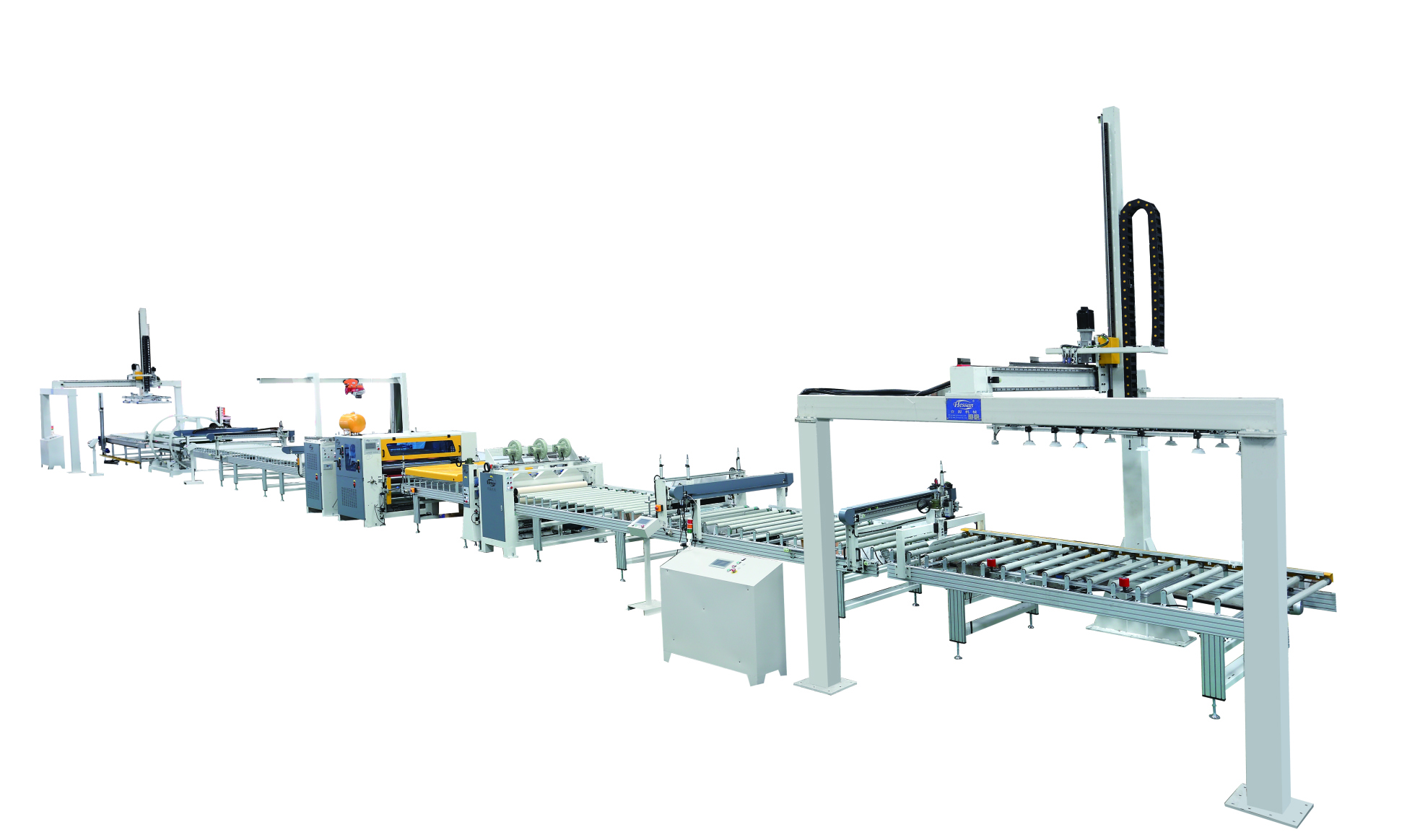

Continuous operation: Fully automated machines can run 24 hours a day (with only occasional stops for refilling and glue changes), making them ideal for use with upstream and downstream production lines (e.g., openers, edgebanders) to achieve automated assembly line operations.

2. High and stable quality of veneer

‘Zero’ defect rate: Fully automated equipment can completely avoid the errors brought by manual operation, such as: air bubbles, scratches, uneven glue, open edge, inaccurate positioning, surface particles, etc., through the precise sensors, PLC control and robotic operation. This is critical for high-end furniture, medical clean boards, lab countertops, and other areas where absolute flatness and flawlessness are required.

Consistency: The machine ensures that each board is laminated exactly the same way, which is impossible to do manually, and is vital for brand maintenance and consistency of colour and texture for large volume orders.

3. Large size and heavy weight of boards

Handling large format (e.g. 8x4ft/2,440x1,220mm) boards, especially thick substrates (e.g. solid wood particle boards, multilayered boards), manual operation requires multiple people to collaborate, which is labour-intensive, with a high risk of safety hazards, and is highly susceptible to scratches or bumps in the handling process. Conveyor belts, suction cup turners and manipulators on fully automated lines can complete these operations easily, safely and without damage.

4. High labour costs and difficulty in recruiting

In regions where labour costs continue to rise, one fully automated machine can replace several skilled workers. In the long run, the savings in wages, social security and management costs are substantial.

At the same time, flat panel laminating is both technical and physical work, the younger generation is not willing to engage in, fully automated equipment is the fundamental way to solve the problem of "difficult to recruit.

5. Pursuing the ultimate production efficiency and beat

fully automated line will be loading, gluing, laminating, pressing and discharging all processes seamlessly, eliminating the waiting time between processes, and compressing the processing time (beat) of a single workpiece to the shortest possible time. This is significant for the pursuit of JIT (just-in-time production) and rapid response of modern manufacturing enterprises.

6. Special materials and processes need to be handled

For example, when dealing with very expensive finishing materials (e.g. high grade solid wood veneers, thin metal boards), the risk of manual lamination is high, and the losses in case of mistakes are huge. Fully automated equipment maximises material utilisation and reduces wastage.

Or if you need to achieve some special processes, such as front and back side laminating at the same time (double laminating), composite laminating (e.g. boards + aluminium honeycomb core + boards), etc., the fully-automatic line is the only efficient and reliable choice.

II. Challenges that may be faced when choosing a fully automated laminating machine

Of course, choosing fully automated also means that the following challenges need to be met:

High initial investment: Fully automated machines are often several times or even tens of times more expensive than semi-automatic ones.

Higher maintenance costs and skill requirements: Specialist maintenance staff are required, and operators' skills are more demanding.

Relatively less flexibility: When changing product types (e.g., large changes in size and material), set-up times are longer than with semi-automatic equipment. More suitable for mass production than for small, sporadic orders with extreme diversity.

In summary: How do you make decisions?

You can ask yourself the following questions:

Production assessment: What is my current average daily/monthly production? Is there a steady growth expected in the future?

Costing: What are my current labour, scrap and overhead costs? How much can I expect to save with fully automated equipment? Calculate the payback period (usually within 1-3 years ideally).

Quality Requirements: Will my customers be able to accept occasional manual handling defects? Is my product positioning low to medium or high end?

Order structure: Are my orders for large quantities of small samples, or small quantities of various samples?

Development plan: Do I plan to upgrade my entire production line towards ‘Industry 4.0’ or a smart factory?

Conclusion:

If your production volume is large enough, quality requirements are stringent, labour costs have become a burden, and you have stable capital investment and long-term development plans, then investing in fully-automatic flat-bed laminating machine is undoubtedly a better choice, which will become a powerful weapon for you to enhance your core competitiveness and achieve large-scale, standardized production.

On the other hand, if your business is mainly small batch, multi-variety customised products, or the initial budget is limited, then a high-quality semi-automatic flat laminating machine may be a more flexible and economical choice.