Cold Laminating Technology Surges to Prominence: Efficiency and Cost Advantages Challenge PUR Laminating, Offering New Options for Furniture Panel Manufacturing!

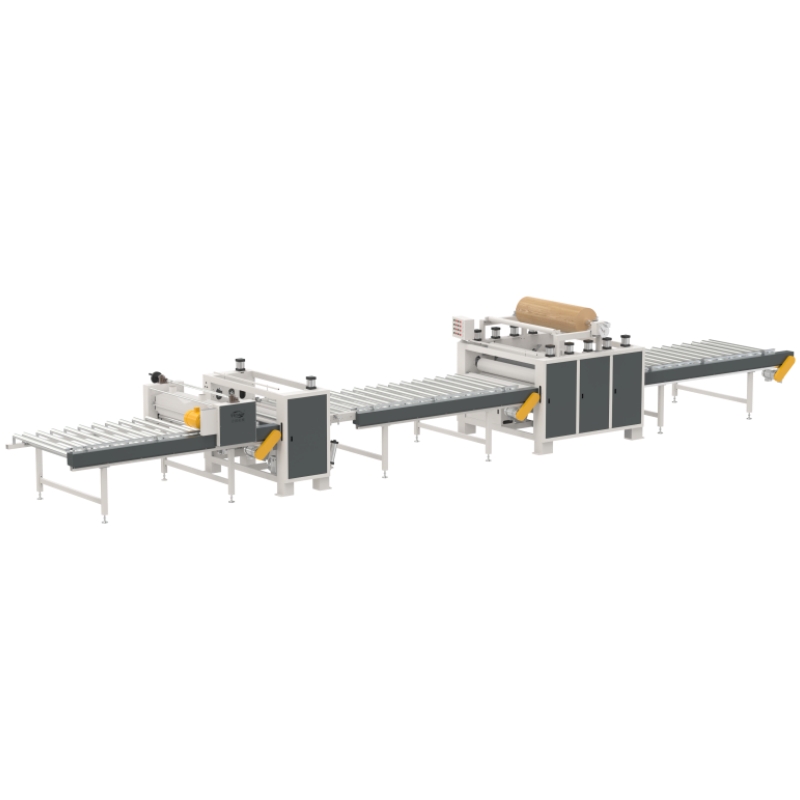

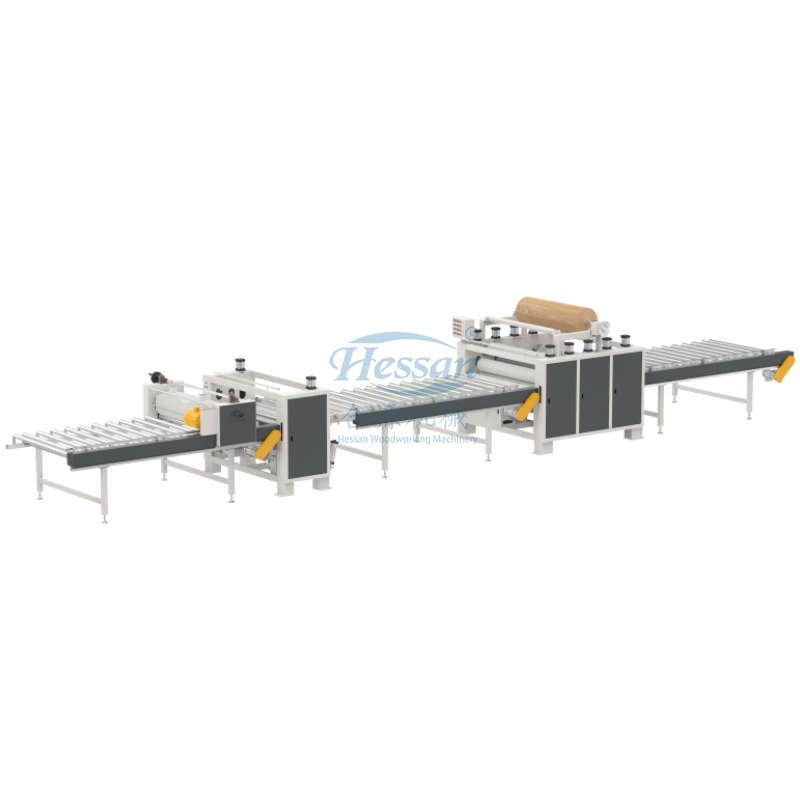

Industry Focus: In the core process of furniture panel manufacturing—precisely bonding decorative paper or PVC film to MDF (medium-density fibreboard), particleboard, and plywood substrates to achieve efficient production and perfect surface finishes—the choice of laminating processes is undergoing significant transformation. Recently, cold laminating technology (Cold Laminating) has gained traction in the industry due to its notable efficiency and cost advantages, posing a strong challenge to the traditional PUR (moisture-curing reactive polyurethane) hot-melt adhesive lamination process.

Core Advantages Drive Surge in Demand for Cold Laminating Machines

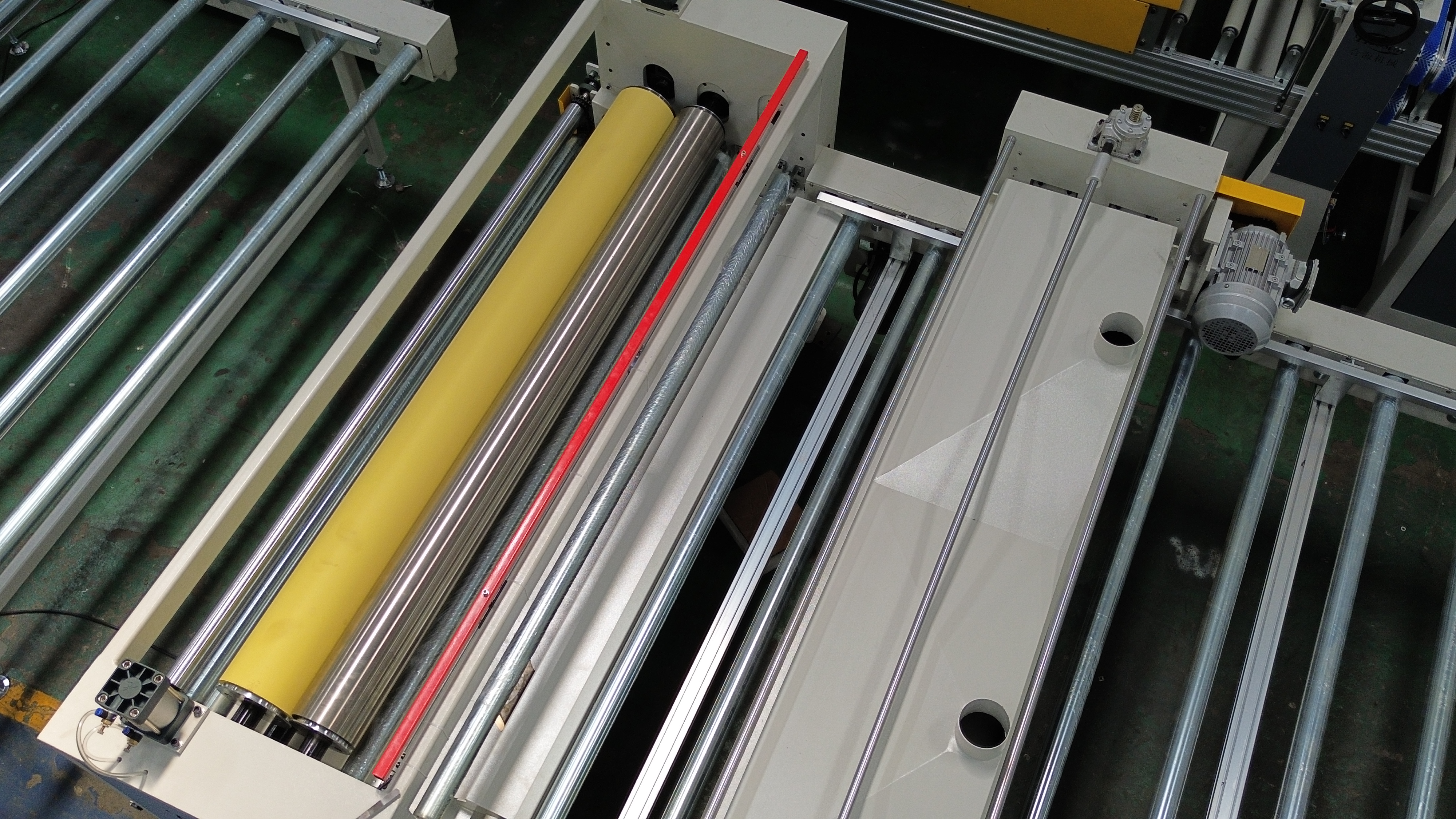

The core of cold laminating technology lies in its unique bonding mechanism that does not require high-temperature heating. This directly translates into multiple competitive advantages, perfectly aligning with the furniture manufacturing industry's urgent need to enhance efficiency and reduce costs:

1. Lightning-Fast Speed: By eliminating the need for hot-melt adhesive heating, melting, and cooling/curing time, cold laminating machines can achieve faster production cycles, significantly improving equipment utilisation rates and over all factory capacity.

2. Energy-saving pioneer: By completely eliminating the high energy consumption requirements of large heating devices (such as glue pots and rollers), cold laminating machines significantly reduce factory electricity costs, aligning with green manufacturing trends.

3. Cost optimiser: Not only do they save electricity, but cold laminating adhesives typically offer better price competitiveness, and the equipment requires relatively simple maintenance (no high-temperature component cleaning or hot melt adhesive carbonisation issues), resulting in significantly reduced overall operational costs.

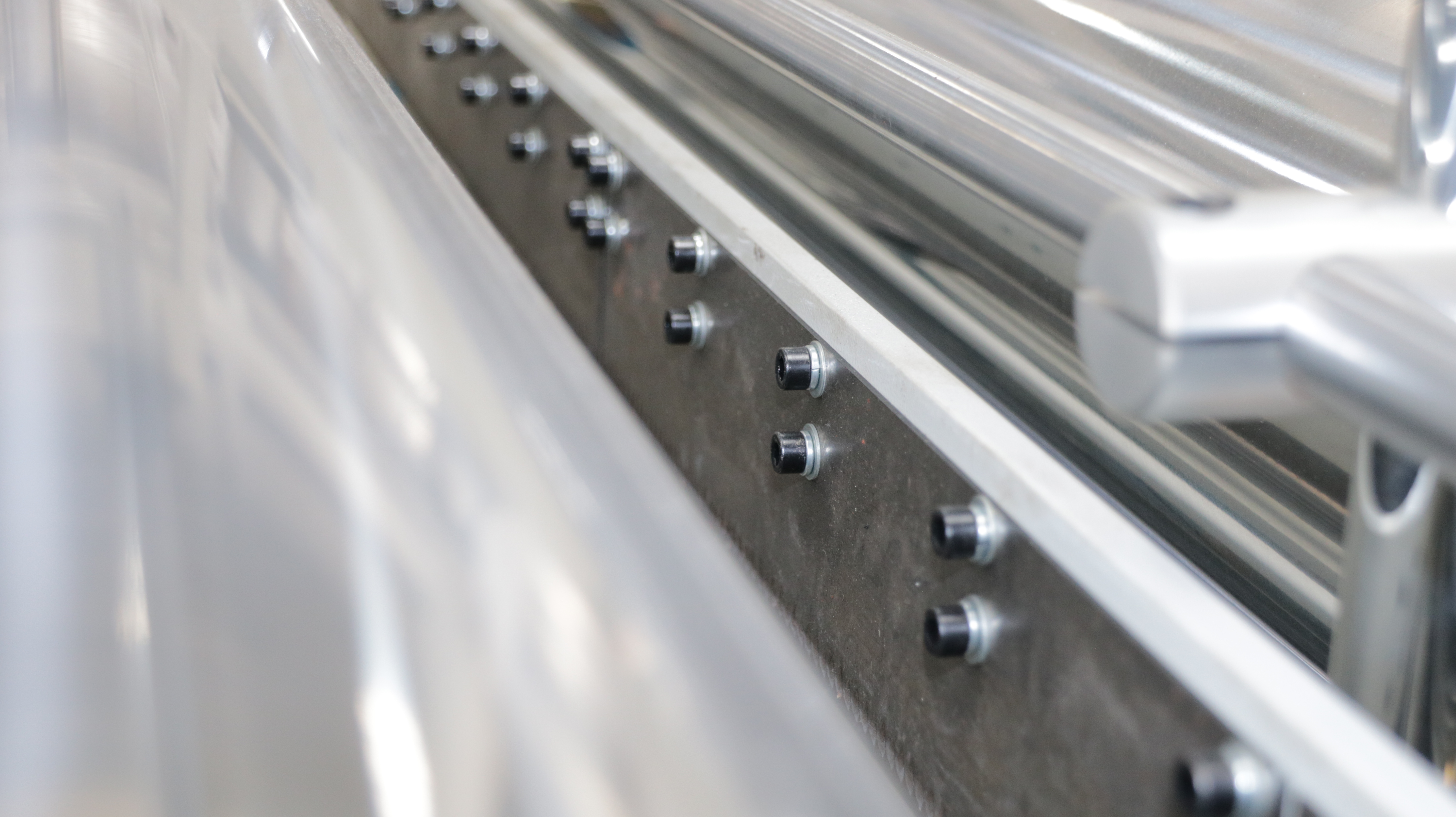

4. Substrate-Friendly: Low-temperature operation (typically ≤60°C) avoids the risk of warping, deformation, or surface damage to heat-sensitive substrates (such as certain specially treated particleboard or thin MDF), expanding the range of applicable materials.

5. Environmental Improvement: Reducing high-temperature work areas helps improve the workshop working environment.

Cold Laminating vs. PUR: Key Process Comparison

| Characteristics | (Cold Laminating) | (PUR Laminating) |

|---|---|---|

| Adhesion Principle | Pressure-sensitive adhesive (no heating required) | Moisture-curing reactive polyurethane adhesive (heating required to melt) |

| Production Speed | 5-25m/min | 5-17m/min |

| Energy Consumption | Lower | Normal |

| Cost | Lower | Normal |

| Base Material Suitable | / | / |

| Initial strength | / | / |

| Final bonding strength/resistance | Excellent (meets most furniture requirements) | Outstanding (extreme heat, chemical and moisture resistance) |

Typical applications | Mainstream furniture panels, interior door panels, decorative mouldings | High-end cabinets, bathroom furniture, panels for extreme environments |

Application focus: efficiently creating perfect surfaces

As industry practice emphasizes, cold laminating technology is particularly suited to the efficient production of furniture panels with high demands on decorative surface effects. By means of a precisely controlled pressure system, the cold laminator ensures a perfect fit between the decorative paper or PVC film and the substrate (MDF, chipboard, plywood) with no air bubbles, no wrinkles, high gloss or precise texture reproduction, and an excellent surface quality of the finished product.

Industry outlook: cold laminating to establish the mainstream position, PUR to hold on to high-end areas

Industry experts generally believe that the maturity and promotion of cold laminating technology is reshaping the furniture panel laminating market pattern. Its unparalleled efficiency, energy-saving features and comprehensive cost advantages, so that it has become a high-volume, standard and high-end furniture panel production process of choice, equipment purchasing enthusiasm continues to rise.

At the same time, PUR laminates, with their ultimate resistance (to heat, humidity and chemicals) due to their nearly irreversible chemical bonding, continue to have irreplaceable core value in the high-end segment where extreme durability is required(e.g., kitchen and bath furniture, lab countertops, outdoor furniture components).

Conclusion:

The rise of the cold laminator does not mean the obsolescence of PUR technology, but rather marks the segmentation and maturity of the furniture panel lamination process. Manufacturers can now more precisely choose the optimal laminating solution based on product positioning, performance requirements, cost budgets and capacity targets. Cold laminating technology is rapidly becoming a strategic investment hotspot for furniture manufacturers in pursuit of scale, cost-effectiveness and consistent quality, thanks to its excellent efficiency, economy and guarantee of perfect surface results. This“hot and cold war”is ultimately driving the industry towards a more efficient, flexible and sustainable development.