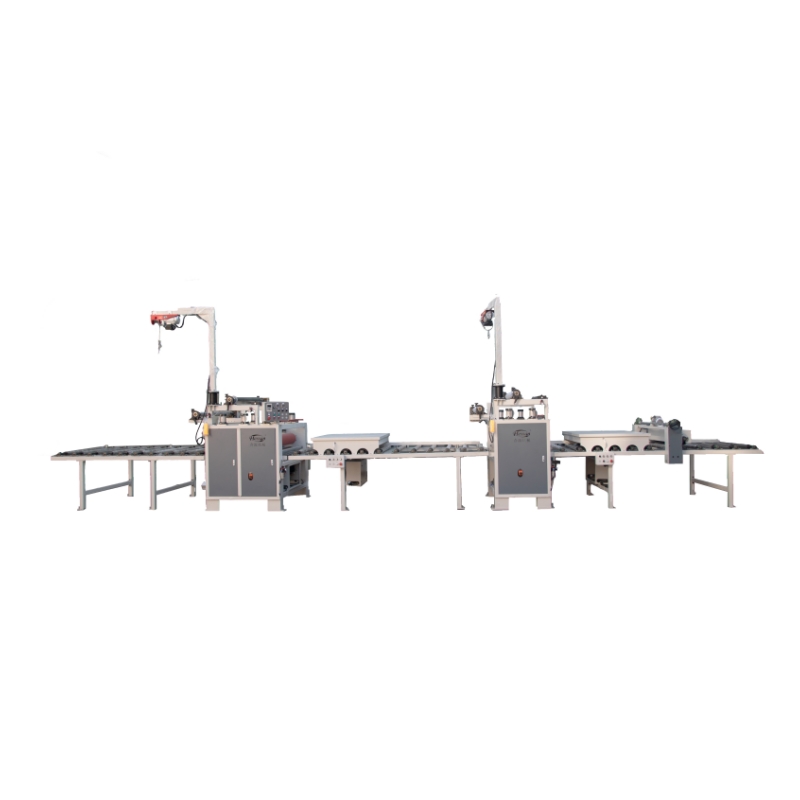

Double Sides Paper Laminating Machine

- Hessan

- China

- 20 Days

- 400PCS/month

Automatic Double Sides Water Glue Paper Laminating Machine Hessan Model :HY-T-350A Description : This is the production line for using cold glue,water base glue sticking paper ,PVC on plywood,MDF,chipboard double sides etc.hydraulic pressing system,automatic feeding/unloading device 1.Automatic feeding machine,2.Convyeor unit ,3.Double side brushing machine,4.Double side glue spreader,5.Double side sticking machine,6.Paper trimming device,7.Auto cutting machine,8.Hot roller press machine,9. Conveyor,10.Automatic unloading machine.

Double Sides Paper Laminating Machine

Hessan Model:HY-T-350A

Description:

This is the production line for using cold glue,water base glue sticking paper ,PVC on plywood,MDF,chipboard double sides etc.hydraulic pressing system,automatic feeding/unloading device

1.Automatic feeding machine

Table lift: 2set

Roller feeding device:1set

Transmission power:2×1.5KW

Hydrualic power: 2×2.2K Manual thickness adjustment

2.Convyeor unit

Roller: φ88×1190 Driven by brushing machine

Panel divider: 1 set

3.Double side brushing machine

Fans: 3×0.25KW

Transmission power:1.5KW

Brushing power:1.1KW

Brushing roller:φ190×1350

Rubber roller:φ120×1350

4.Double side glue spreader

Transmission power: 3KW

Lifting power:0.37KW

Coating roller:φ270×1350,EPDM

Dosing roller:φ156×1350,chrameplate surface

Double side electrial thincknes adjust

Front and back folding conveyors

5.Double side sticking machine

Transmission power: 2×1.5kw

Pnuematic pressing Lifting power: 0.37kw

PVC heating roller:2×2kw

Sticking roller:φ270×1350,

Rubber Bottom roller: φ270×1350,

Steel Foil expending roller:φ125×1350;

Chrameplate surface Crane:0.55kw

Expending shalft:φ74×1350

Tension brake:2×100N.M

6.Paper trimming device

Sanding motor:4×0.75kw

7.Auto cutting machine

Cutting power:0.37kw

Sever motor power: 0.75kw (for precisely chasing the panels)

Transmission power:0.75kw

Conveying roller: φ66×1410mm

8.Hot roller press machine

Transmission power: 3kw

Hydrualic pressing power:2.2kw

Lifting power: 0.37kw

First pair of pressing rollers: Rubber: φ320×1350

Steel rollers:φ320×1350

Chrameplate surface Heating power:6×7.5kw(oil heating)

9. Conveyor: Roller: φ66×1410

Transmit power: 0.75kw

10.Automatic unloading machine

Table lift:2 sets

Tranmsission power:2×1.5kw

Hydrualic pressing power:2×2.2kw

Working data

Size of board:1220mm×2440mm

Thickness:2.5-40mm Speed : 5-25m/min

Transmissin power: 31.27KW

Heating pwer: 75KW

Size of machine: 23.5m(L)×3.5m(W)×2.9m(H)Invertor speed control PLC touch screen operation.

China, USA, Australia, Poland, Russia, Uzbekistan, Turkey, Mexico, South Korea, Japan, North Korea, Egypt, Saudi Arabia, Iran, India, Pakistan, Malaysia,Singapore,Indonesia, Vietnam, Myanmar, Thailand, Kenya.etc.more than 30 countries....more